SV

SV7-IP Quick Setup Guide

Requirements

▪A compatible servo motor.

▪A small at blade screwdriver for tightening the connectors (included).

▪A personal computer running Microsoft Windows 98, NT, Me, 2000, XP, Vista, or 7.

▪Quick Tuner™ software (version 2.2.17 or later) available at www.applied-motion.com/products/software.

▪A CAT5 network cable (not included).

▪For more detailed information, please download and read the SV7 Hardware Manual, available at www.applied-motion.com/support/manuals.

To begin, make sure you have the following equipment:

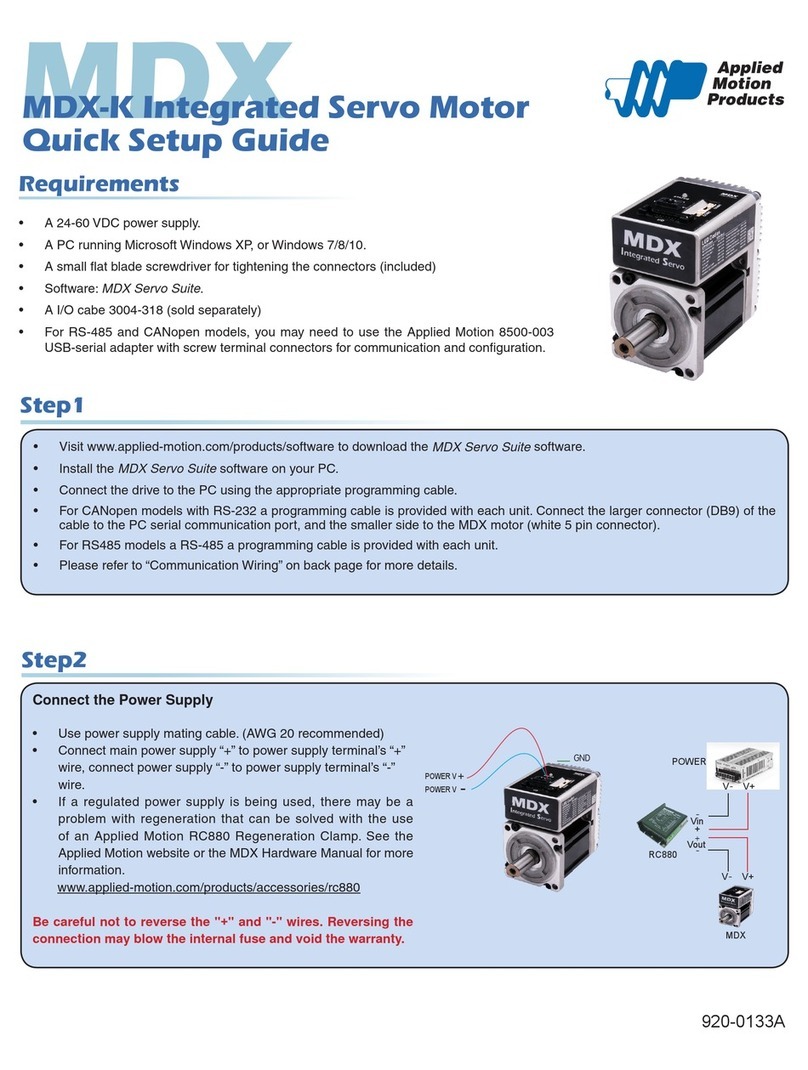

Step 1

a) Download and install the QuickTuner™ software.

b) Launch the software by clicking:

Start / Programs / Applied Motion Products / Quick Tuner

c) Connect the drive to your network or PC using a standard CAT5 cable.

d) Select an appropriate IP address using the rotary switch on the SV7-IP. For more information

about network congurations and IP addressing, please consult the SV7 Hardware Manual.

Step 2

Wire the drive to the DC power source.

(Do not apply power until all connections to

the drive have been made)

Note, the SV7 drives accept DC power from

24-80 VDC.

For a non-Applied Motion Products motor, please

refer to your motor specs for wiring information.

Be sure to connect the motor case ground to the

grounding screw as indicated, leaving the last

pin on the motor/power connector unconnected.

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

V+

V-

Motor A (or U) phase

Motor B (or V) phase

Motor C (or W) phase

Motor

Grounding

Screw

a) Connect the I/O

b) Connect the Encoder

▪Applied Motion motor cables

are available with connectors

that mate directly to the

encoder connector on the drive.

Step 4

encoder Z+ (5)

Hall 1-(10)

encoder B- (4)

Hall 1+ (9)

encoder B+ (3)

Hall 3+ (13)

Hall 3- (14)

GND (15)

(12) Hall 2-

(11) Hall 2+

(6) encoder Z-

(1) encoder A+

(7) +5VDC 200mA

(2) encoder A-

(8) GND

Front View

ENCODER

Front View

X COMMON

not used

X3 / Enable

X5 / CWJOG

X4 / Alarm Reset

Analog IN2

Analog IN1

X2 / DIR-

X2 / DIR+

X1 / STEP +

X1 / STEP -

GND

GND

+5V OUT

Y COMMON

Y3 / FAULT

Y2 / MOTION

Y1 / BRAKE

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

2

3

1

19

20

21

22

23

24

25

X6 / CCWJOG

IN/OUT

X8/CCWLIMIT+

X8/CCWLIMIT-

X7/CWLIMIT-

X7/CWLIMIT+

Y4-

Y4+

920-0053 rev A