7.1.9 Servo On Status Output ...........................................................................................................................77

7.1.10 Timing Diagram .....................................................................................................................................78

7.1.10.1 Timing Diagram at Power up....................................................................................................................... 78

7.1.10.2 Timing Diagram for Fault alarm .................................................................................................................. 78

7.2 Position Mode ....................................................................................................................................................79

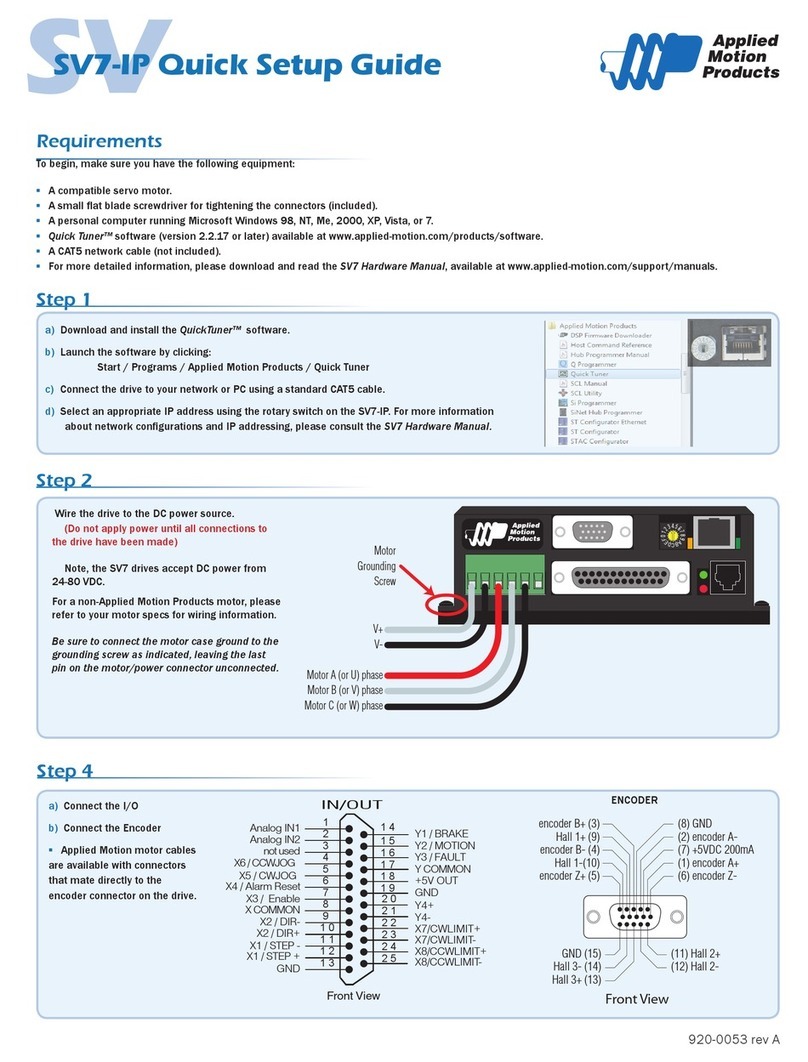

7.2.1 Digital Pulse Position Mode Connection Diagram....................................................................................79

7.2.2 Input Pulse Type And Input Noise Filter ...................................................................................................80

7.2.3 Input Pulse Dividing Ratio Setting and Dividing Switch............................................................................82

7.2.4 Pulse Inhibit .............................................................................................................................................83

7.2.5 Electronic Gearing Ratio............................................................................................................................84

7.2.6 Jerk Smoothing Filter................................................................................................................................85

7.2.7 In-Position Error Output............................................................................................................................85

7.2.8 Gain Parameters For Position Control Mode.............................................................................................86

7.2.9 Software Configuration For Position Mode...............................................................................................87

7.3 Velocity Mode ....................................................................................................................................................88

7.3.1 Velocity Mode Connection Diagram..........................................................................................................89

7.3.2 Parameter Settings For Analog Velocity Control Mode .............................................................................90

7.3.3 Basic Settings For Analog Velocity Control Mode.....................................................................................91

7.3.3.1 Command Signal For Analog Velocity Mode ................................................................................................ 91

7.3.3.2 Analog Velocity Gain..................................................................................................................................... 92

7.3.3.4 Analog Input Deadband................................................................................................................................. 93

7.3.3.5 Run/Stop And Direction Signal .................................................................................................................... 93

7.3.3.6 Torque Limit ................................................................................................................................................. 94

7.3.3.7 Target Velocity Reached ................................................................................................................................ 94

7.3.3.8 Velocity Mode Control Type.......................................................................................................................... 95

7.3.3.9 Velocity ripple............................................................................................................................................... 96

7.3.4 Analog Input Filter ....................................................................................................................................97

7.3.5 Software Configuration for Analog Velocity Mode.....................................................................................98

7.4 Torque Mode .......................................................................................................................................................99

7.4.1 Analog Torque Mode Connection Diagram ..............................................................................................100

7.4.2 Parameters For Analog Torque Mode.......................................................................................................101

7.4.3 Basic Settings For Analog Torque Mode ..................................................................................................101

7.4.4 Software Configuration for Analog Torque Mode .....................................................................................106

7.5 Position Table Mode...........................................................................................................................................107

7.5.1 Linear motion...........................................................................................................................................107

7.5.1.1 Linear Motion Software Configuration ......................................................................................................... 107

7.5.1.2 Basic Configuration ..................................................................................................................................... 108

7.5.1.3 Homing settings........................................................................................................................................... 109

7.5.1.4 Print............................................................................................................................................................. 109

7.5.1.5 Position Definition ....................................................................................................................................... 109

7.5.1.6 Simulate....................................................................................................................................................... 110

7.5.1.7 Linear motion input definition...................................................................................................................... 110

7.5.2 Rotary motion .........................................................................................................................................110

7.5.2.1 Rotary motion software configuration .......................................................................................................... 111

7.5.2.2 Rotary motion input definition...................................................................................................................... 112

8 Parameters and Functions .............................................................................................................................. 113

8.1 Parameter Category............................................................................................................................................113

8.2 Parameter List ....................................................................................................................................................113

8.3 Parameter Description........................................................................................................................................118

9 Communication .............................................................................................................................................. 140

9.1 RS-232 communication .....................................................................................................................................140

9.1.1 What is SCL?...........................................................................................................................................140

9.1.2 RS-232 Connections................................................................................................................................140

9.2 RS-485 Communication.....................................................................................................................................141

9.2.1 RS-485 PIN definition .............................................................................................................................141

9.2.2 RS-485 Connection Method ...................................................................................................................142

9.3 Modbus/RTU Communication............................................................................................................................143

9.3.1 Data Encoding..........................................................................................................................................143