© 1998 - 2022 Applied Photonics Ltd Page 3 of 41

1 Introduction

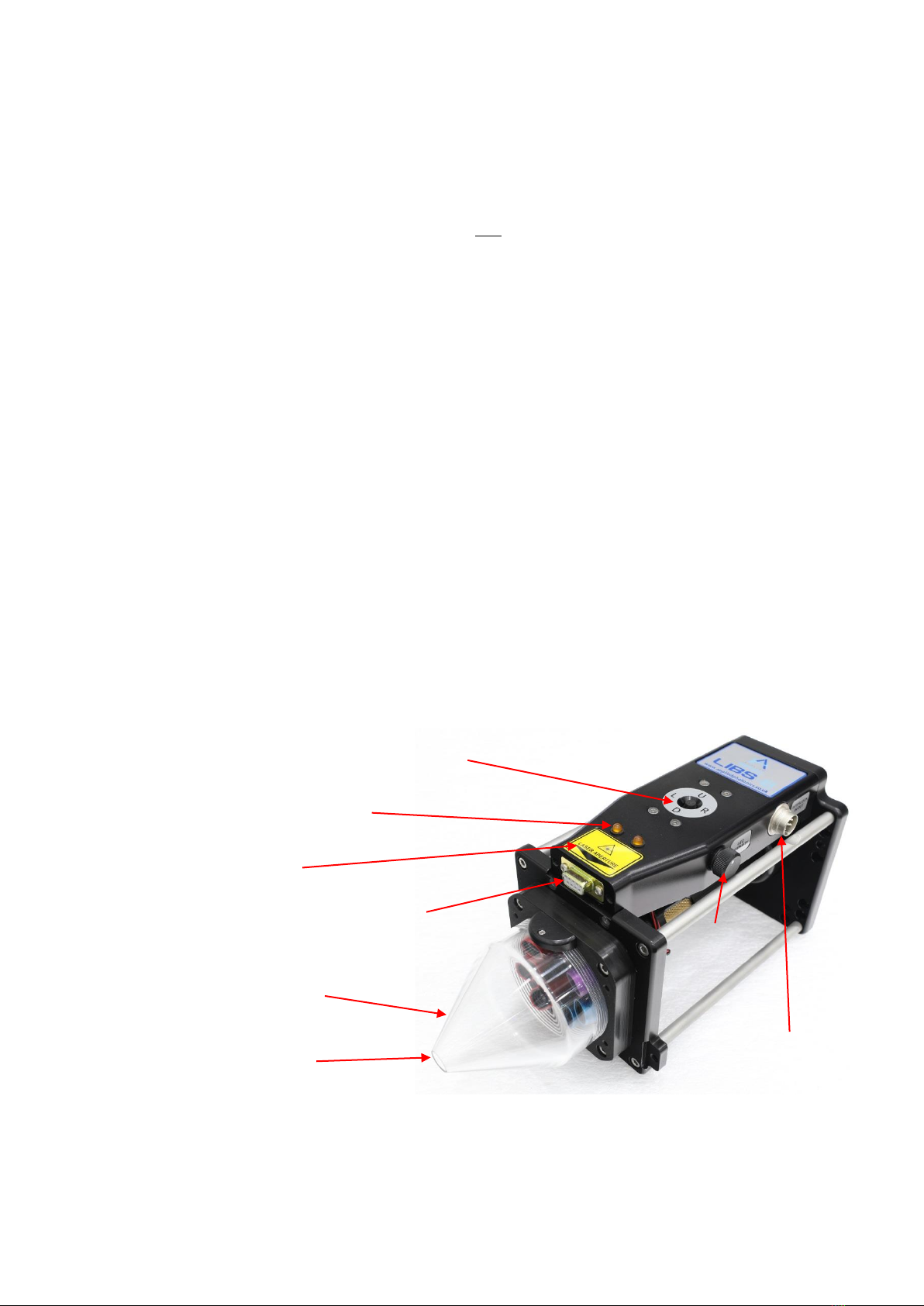

The modular Laser-Induced Breakdown Spectroscopy (LIBS) system described in this User’s Manual is

designed to be a highly versatile product for use by research scientists, application engineers and OEMs.

Essentially a “LIBS system building block”, the LIBS-6 and LIBS-8 modules may be used together with a

variety of Q-switched Nd:YAG lasers and optical spectrometers to form a customised, modular LIBS

system tailored to suit the requirements of a specific application or experimental research project. The

LIBS modules remove the need for the research scientist or application engineer to design and construct

their own laser focussing optics and plasma light collection optics by combining these features into a

compact, integrated and easy to use device. An optional imaging kit may be added to the LIBS module,

increasing further its functionality and versatility.

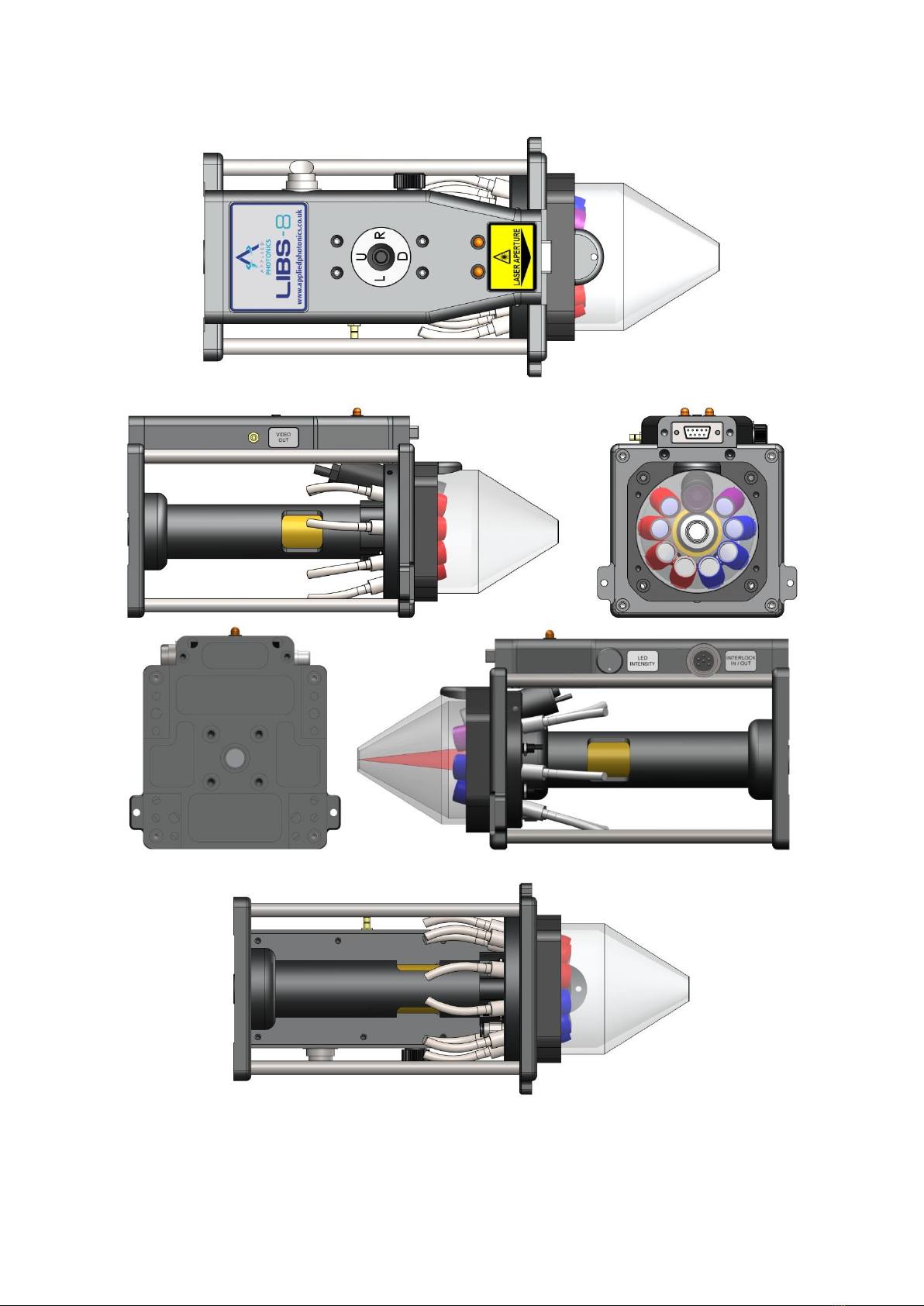

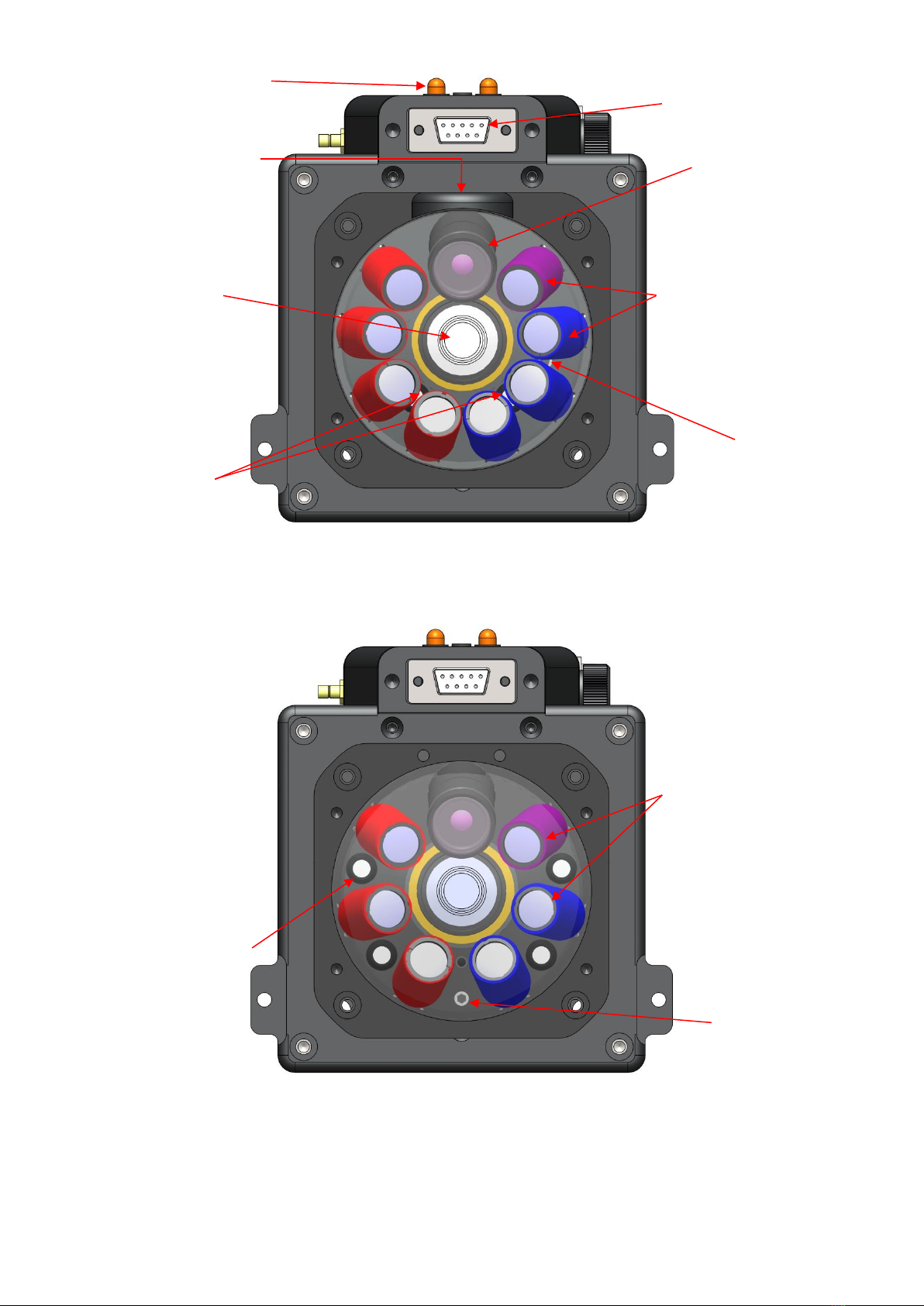

The modular LIBS system described in this User’s Manual comprises the following main components: a

LIBS-6 module fitted with an optional imaging camera (IMG-HR), an AP-Nano adaptor platform, a

Litron Nano SG 150-10 laser, a SpectroModule-6 multi-channel LIBS spectrometer, an SC-2L modular

sample chamber and a computer running LIBSoft software. In some sections of this User’s Manual, the

following components and devices are also described: LIBS-8 module, SpectroModule-8 six-channel

LIBS spectrometer, Litron Nano LG 300-10 laser, an XYZ-750 modular sample chamber and a dual-

camera imaging system (IMG-HR-2).

This User’s Manual provides the necessary information needed to configure the LIBS equipment and how

to operate the equipment safely. It is assumed that the user is familiar with the safety issues arising from

the use of high-power lasers and will have preferably been trained in the safe use of high-power (Class 4)

laser products.

2 Safety

2.1 Laser radiation

The modular LIBS system utilises a high-power Q-switched Nd:YAG laser (Class 4) and so it is

imperative the equipment is operated only by suitably trained and experienced persons who are fully

aware of the hazards inherent to this type of high-power laser equipment. It is imperative also that, prior

to using the equipment, an appropriate risk assessment is conducted in such a way as to take account of

the proposed use of the equipment, the environment in which the equipment is to be operated, and how its

use may affect people who are not directly involved with the use of the equipment.

Example of a laser warning product label

The modular LIBS system is designed to meet the laser safety requirements of the relevant European

standards (BS EN 60825) and USA standards (ANSI Z136.1). Although the modular LIBS system is

supplied with a sample chamber which provides adequate containment of the laser radiation to Class 1

Accessible Emission Limits, it is possible for the user to operate the LIBS equipment without the sample

chamber (i.e. operation in “open beam” mode as may be required for certain types of experiment).

Accordingly, it is necessary to consider the modular LIBS system to be a Class 4 Laser Product and so,

by definition, the equipment poses a risk of personal injury (eye, skin injury) and poses a fire risk. As