chiefs ST164 User manual

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

ST164 Two Way Chemical Injector

The ST164 is a manual, two chemical dispensing unit, specifically designed for use with Nerta and Chiefs touchless

cleaning products.

Most fleets generally have a variety of vehicles that require more than one cleaning product. The ST164 can dispense

and automatically dilute up to two chemicals, pre-set at the correct ratios (from 100:1 to a maximum of 10:1)

The ST164 is designed to work under high pressure and is connected to the wash bay pressure cleaner(s). It can

dispense both foaming single step products and low and high PH dual products, under high pressure.

The ST164 is made by RM Suttner in Germany. It will cope with harsh wash bay conditions and is safe to use with

both low and high pH water soluble products.

The ST164 is supplied with a number of standard accessories, dependent on the wash bay and chemical

requirements, which are listed in the following section.

In addition to the standard accessories, there may be a requirement for additional equipment such as hose reels,

high pressure hose, fittings etc. This will be discussed and documented on a site visit with your Chiefs representative.

The ST164 is setup at our factory to match the specifications of the pressure cleaner. The chemical injector in ST164

relies on the pressure rating (psi) and the flow rate (lpm) to operate correctly and perform to maximum efficiency.

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

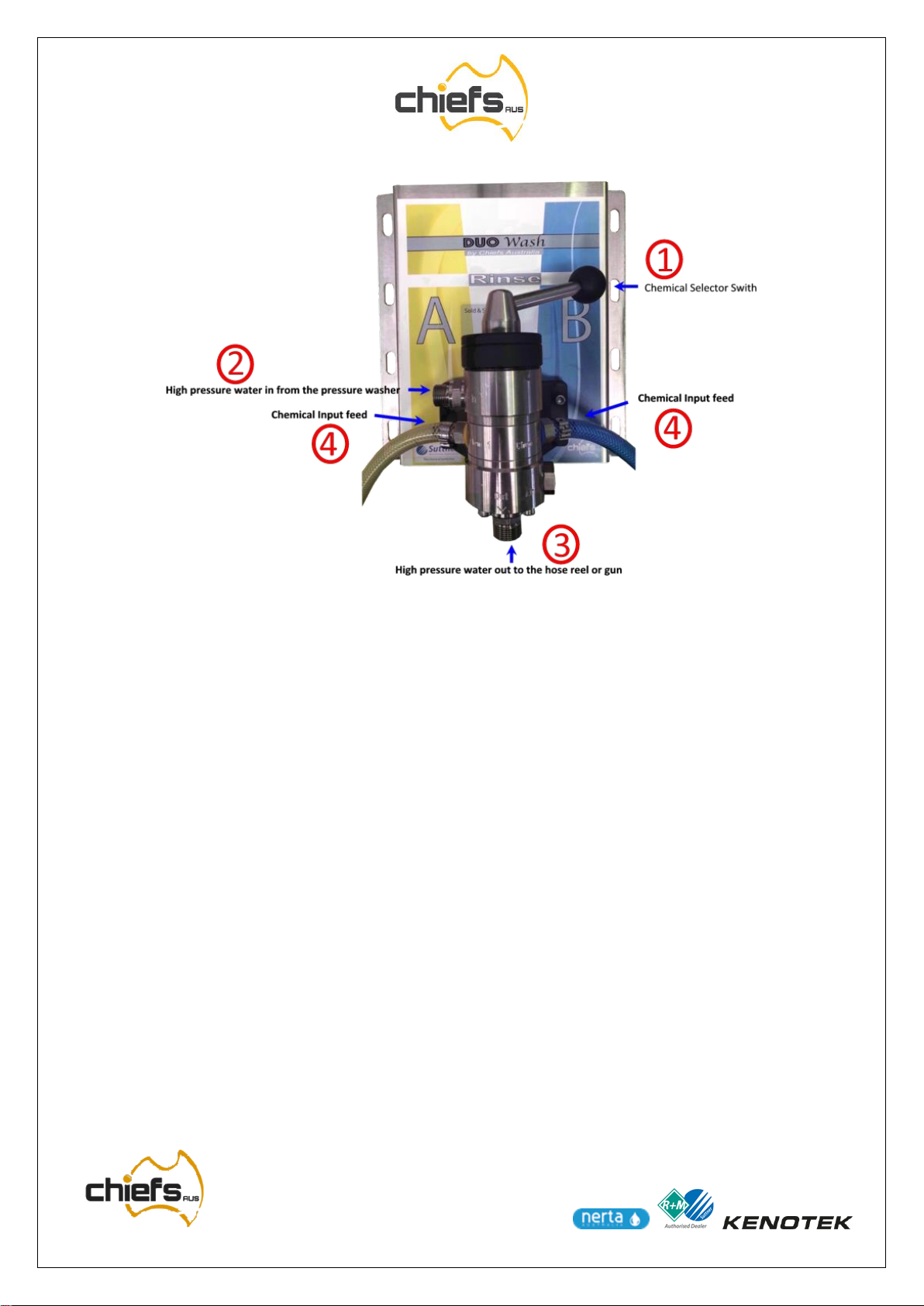

1. Chemical Selector Switch

The chemical selector switch is used to select the required chemical and corresponds via colour to the

chemical input feeds, i.e. if you select green the chemical line attached to the green input feed will draw that

chemical.

2. High Pressure water in from pressure cleaner.

A high-pressure connecting hose is required to connect your pressure cleaner to the Injecta Chem. The

length will depend on the distance between your pressure cleaner and Injecta Chem. When this hose is

made up, ensure the correct fittings are attached.

3. High Pressure water out to the hose reel or gun

Your high-pressure hose connects to this connector which comes standard with a 3/8” BSP thread.

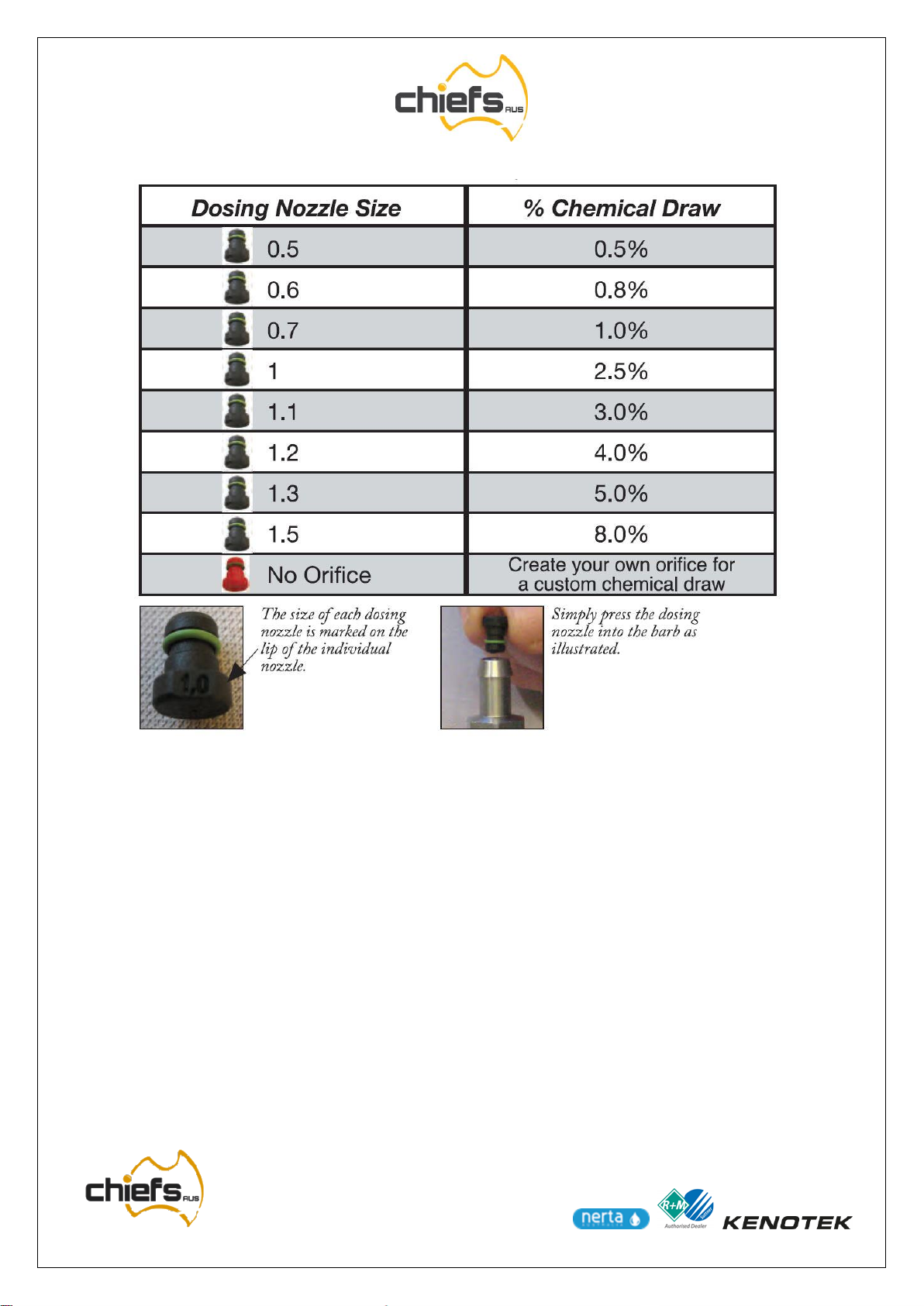

4. Chemical input feeds (lid kits supplied for 20L, 25L, 200L or 1000L). This is also where the dosing nozzle to

determine the chemical ratio is inserted. This is generally pre-set on your injector and depending on your

setup you may be supplied with a dosing nozzle kit. Please see the below diagram for more information.

Please note that these dosing nozzles are specifically setup for your wash bay requirements and it is VERY

IMPORTANT that these nozzles are not tampered with or removed as this will strengthen the soap to water

ratio and at higher concentrations could cause damage.

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

ST-164 Injector Nozzle Sizes (Plug-In)

Letter Guide

Product ID

Product SKU

Nozzle Size

Diffuser Size

C

124421

ST-164

1.6

2.0

A

124488

ST-164

1.7

2.0

B

124855

ST-164

1.4

1.7

H

124944

ST-164

1.3

1.7

J

125158

ST-164

1.8

2.3

F

125203

ST-164

1.5

1.7

R

125204

ST-164

1.9

2.3

125205

ST-164

2.0

2.3

ST-164

1.7

2.0

K

124388

ST-164

2.2

2.8

L

125389

ST-164

2.0

2.8

M

125390

ST-164

1.2

1.7

N

125391

ST-164

2.4

2.8

P

125392

ST-164

2.3

2.8

The ST164 Two Way Chemical Injector will either be installed by a Chiefs technician, accredited dealer or by

customer workshop staff.

The diagram below illustrates a typical layout of an Injecta Chem installation

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

Before installation, the following will be required.

1. High pressure hose between the pressure cleaner and ST164 Two Way Chemical Injector. Ensure the correct

length is measured and that the correct fittings are ordered. The ST164 Two Way Chemical Injector has a

3/8” BSP male, which needs to match the outlet of the pressure cleaner. –Installation process point 2

2. Should any high-pressure fittings be required, ensure that they are correctly rated for the pressure cleaner.

Installation process

1. Secure the ST164 Two Way Chemical Injector to a stable surface as close to the pressure cleaner as possible,

via the mounting bracket at the back of the ST164 Two Way Chemical Injector.

2. Attach the high-pressure hose from the pressure cleaner outlet to the ST164 Two Way Chemical Injector

inlet

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

3. Attach the high-pressure hose from the gun or hose reel to the ST164 Two Way Chemical Injector outlet.

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

4. Attach the supplied chemical hoses and lid kits to the chemical inlet feeds.

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

Read before Operating or installing Equipment

WARNING - Some equipment can cause death or serious Injury if used or operated incorrectly. Read and understand

these instructions carefully before installing or using this equipment. Know the controls and how to stop the unit

quickly in an emergency. The safety and those around you is your responsibility.

WARNING –Your own Risk Assessment should be carried out before commencing any work. Five steps to basic risk

assessment.

1 - Identify the hazards

2 - Decide who might be harmed and how

3 - Evaluate the risks and decide on precaution

4 - Record your findings and implement them

5 - Review your assessment and update if necessary.

Personal Protective Equipment (PPE)

Always wear correct and appropriate Personal Protective Equipment (PPE) for the job at hand, such as but not

limited to:

•Safety glasses or goggles. - Ear muffs or ear plugs - Dust mask or respirator - Protective gloves - Close fitting

protective clothing - Hard hat / hairnet - Protective or safety boots and footwear - Weld mask - Harnesses.

•Be alert and cautious when wearing hearing protection as your ability to hear warnings (shouts, alarms etc.)

is restricted.

•You must do your own risk assessment with regard to the correct PPE to wear. Refer to the General Safety

Guide

•Do your own risk assessment for all jobs to be undertaken.

•Seek advice from your doctor if you suspect you have any medical condition that may be affected by manual

work or the operation of equipment.

•Do not use machinery if you feel tired or under the influence of alcohol, drugs or medication. Do take regular

rest breaks.

•Do not operate equipment that you are not licensed, unfamiliar with or are not competent to operate. Never

let untrained people use the equipment.

•Ensure you know how to operate it safely and be able to shut it down correctly in an emergency or if you

experience unexpected movement.

•Check controls for proper response. Shut down the machine or equipment if a fault is detected. Do not try to

repair faulty equipment.

•Check the condition of the machine and equipment at the start and end of each day or shift and report any

damage or defects. Do not operate if faulty.

•Operate in clear open spaces were possible and if not possible be conscious of your surroundings and

consider having an observer stand by.

•You should never operate high risk equipment without someone observing you at all times.

•Ensure clear access and egress to where you are working. Always keep the work area well-lit and hazard

free. A tidy work area is a safe area.

•Always have secure footing and balance and firm two handed grip. Never work on damp, wet or slippery

surfaces. Use harnesses where applicable.

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

•Always run and operate machines and equipment on flat, level and solid ground. • Do not overreach. Hand

tools should not be used above shoulder height. Keep all controls, handles and levers clean, dry and free

from oil & fuel etc.

•Prolonged use of hand operated equipment exposes the user to vibrations. Stop using the tool if they feel

numbness or inability to feel temperatures.

•Always keep guards in place and in working order. Do not continue to use faulty or damaged equipment.

Keep hands away from moving parts.

•Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry which may get caught in the

moving parts. Use hair nets.

•Select the correct equipment for the job you are undertaking. Always use the right tools. Keep hands and

fingers away from pinch areas.

•Never permit children, other people or animals to loiter near the work area.

•Do not fool around while operating equipment; always keep the machine under control. Never leave a

machine running unattended.

•Never force a tool, blade or attachment to do a job for which it was not designed. When using attachments,

ensure they are fitted correctly and practice the operation before beginning work. Isolate power source

before changing accessories, attachments, blades, drill bits or parts.

•Do not rush or take risks when operating equipment. Never force a machine, let the machine do the job.

•Select the correct equipment for the job you are undertaking. Always use the right tools. Keep hands body

away from pinch areas & moving parts.

Safety Guide for use of this Equipment

•Never direct the high-pressure spray onto bare skin as fluid may enter blood stream and cause death or

serious injury.

•Never aim the jet in the direction of people, animals, electric installations or any other electrical conductors

•Ensure all guards are in place before operating machine. Never operate petrol engines in enclosed area.

•Use only high-pressure hoses and fittings that are supplied with this unit. Never attempt to repair defective

high-pressure hoses by yourself.

•Water jets resulting from leaks may be dangerous. They should always be immediately rectified.

•Never attempt to exchange the gun or disconnect the hoses before the high-pressure water cleaner is

switched off and the pressure has been released.

•Always maintain a firm foothold. Do not use on a ladder or any other insecure support.

•Do not drag the machine by the hose.

•Lance and gun should always be held with both hands. Place the high-pressure water cleaner as far away

from the cleaning area as possible.

•Never lever the machine running when not in use and always release the pressure. Even if not using for short

periods of time.

•After use, switch off the high-pressure water cleaner and shut off the water supply. Always release the

pressure by pulling the trigger after each time you shut the unit down.

This is a Guide only. Use your own judgment. Do not use or operate this equipment if you are unsure or in doubt of

its capabilities, designed use, or its proper operation. For further Information, contact Chiefs Australia and ask for

ABN 23 604 979 688 Nerta QLD Pty Ltd t/as Chiefs Australia

P: 07 5493 8868

M: 0476 350 552

A: 3/6 Textile Avenue Warana QLD 4575

E: clientsupport@chiefsaustralia.com

chiefsaustralia.com

more advice or instruction with regard, to the safe operation of this equipment. If the equipment is not operating

correctly, or not doing the job you expected, do not continue. Do not attempt repairs. Please contact Chiefs Australia

and they will take the appropriate action, which may require the unit to be returned to the branch for exchange or

repair.

Run off from roads, drains and gutters causes poor water quality and can be harmful to fish and wildlife.

•Where waste water consists only of soil and organic matter (no oils or chemicals) it is suitable to dispose of

waste water into a garden or grassed area

•Wastewater containing any oil or chemicals must be collected by an appropriate regulated waste company.

For permanent situations, Council approval must be obtained for waste to be disposed of via the sewer

system under a Council Trade Waste permit.

•Use sandbags or a portable bund that to prevent waste water from entering drains

•Sweep up all waste material rather than hosing down

•Avoid using detergents, oils, pesticides or chemicals near drains, gutters and waterways

•Work on a grassed or gravelled area away from drains, roadside gutters and waterways

•Use a bucket to collect waste water for reuse or proper disposal

•Store all detergents, solvents, oils or any other chemicals in a secure area

•Collect all waste and use a licensed recycling operator or disposal facility

•Clean up spills or leaks using dry absorbent materials such as kitty litter, rags or a bund

•Use as little water as possible, or use trigger hoses where necessary

•Ensure all staff are aware of their environmental responsibilities

•Under the Environmental Protection Act, allowing polluted waste water to enter stormwater drains and

roadside gutters and waterways is an offence and non-compliance may result in an on-the-spot fine as

penalties apply.

Remember

•Stormwater is not treated before entering our local creeks, rivers and waterways. Everyone has a

responsibility to keep our waterways clean

Please note to ensure wash bay compliancy with your local council.

Popular Laboratory Equipment manuals by other brands

Giatec Scientific

Giatec Scientific SURF user manual

Biomeme

Biomeme Franklin three9 instructions

Sartorius stedim

Sartorius stedim Sartobind S manual

Ocean Optics

Ocean Optics HPX-2000 Installation and operation

Prestige medical

Prestige medical Classic 2100 operating instructions

Hach

Hach HQ440d Basic user manual

BioLAB

BioLAB BBAL-108 Operation manual

Izon

Izon AUTOMATIC FRACTION COLLECTOR V2 user manual

Conair

Conair 18 Series user guide

Hellma Analytics

Hellma Analytics 3in1 FLOW-THROUGH CUVETTE instruction manual

Bruker

Bruker 500'54 Ascend ULH user manual

NuAire

NuAire LabGard NU-540-300 Operation and maintenance manual