2

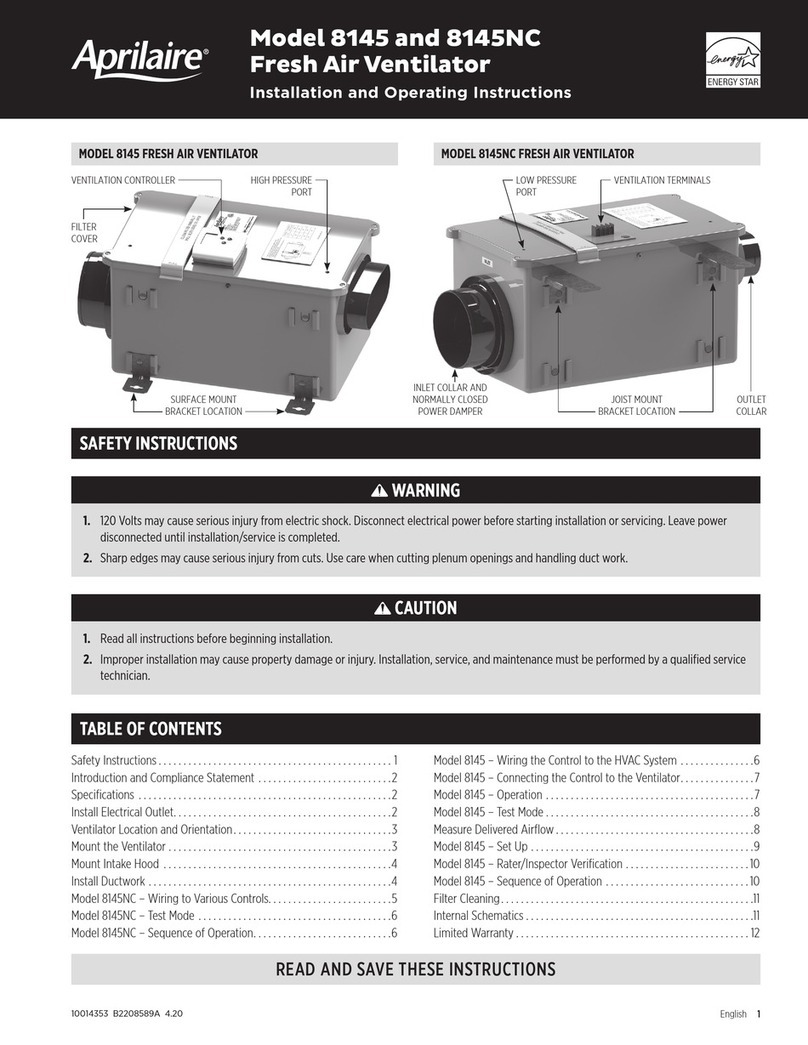

SAFETY INSTRUCTIONS

WARNING

1. 120 Volts may cause serious injury from electric shock. Disconnect electrical power before starting installation or servicing.

Leave power disconnected until installation/service is completed.

2. Sharp edges may cause serious injury from cuts. Use care when cutting plenum openings and handling duct work.

CAUTION

1. Read all instructions before beginning installation.

2. Improper installation may cause property damage or injury. Installation, service, and maintenance must be performed by a

qualied service technician.

TABLE OF CONTENTS

Safety Instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2

Introduction and Compliance Statement � � � � � � � � � � � � � � � � � � � � � � � � 3

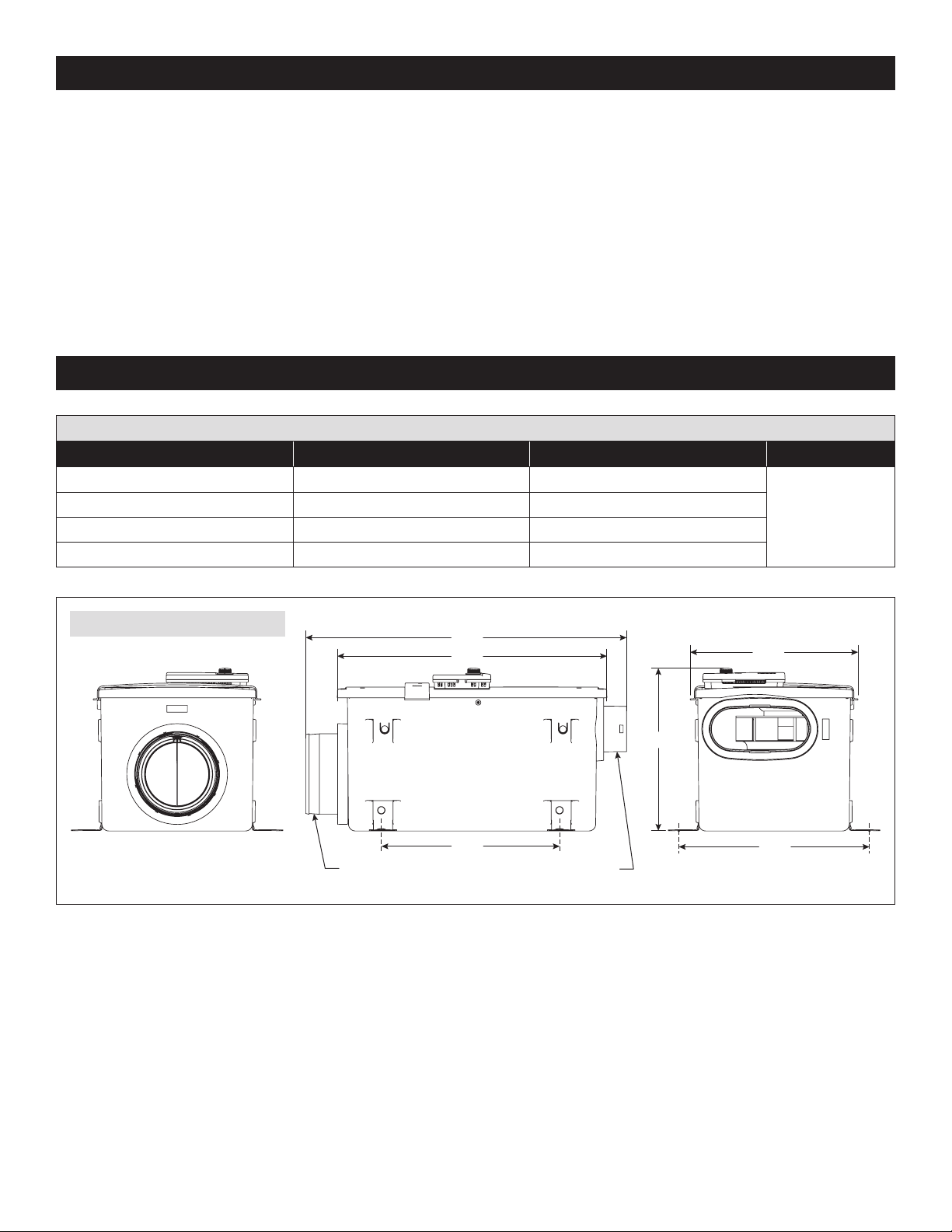

Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Install Electrical Outlet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

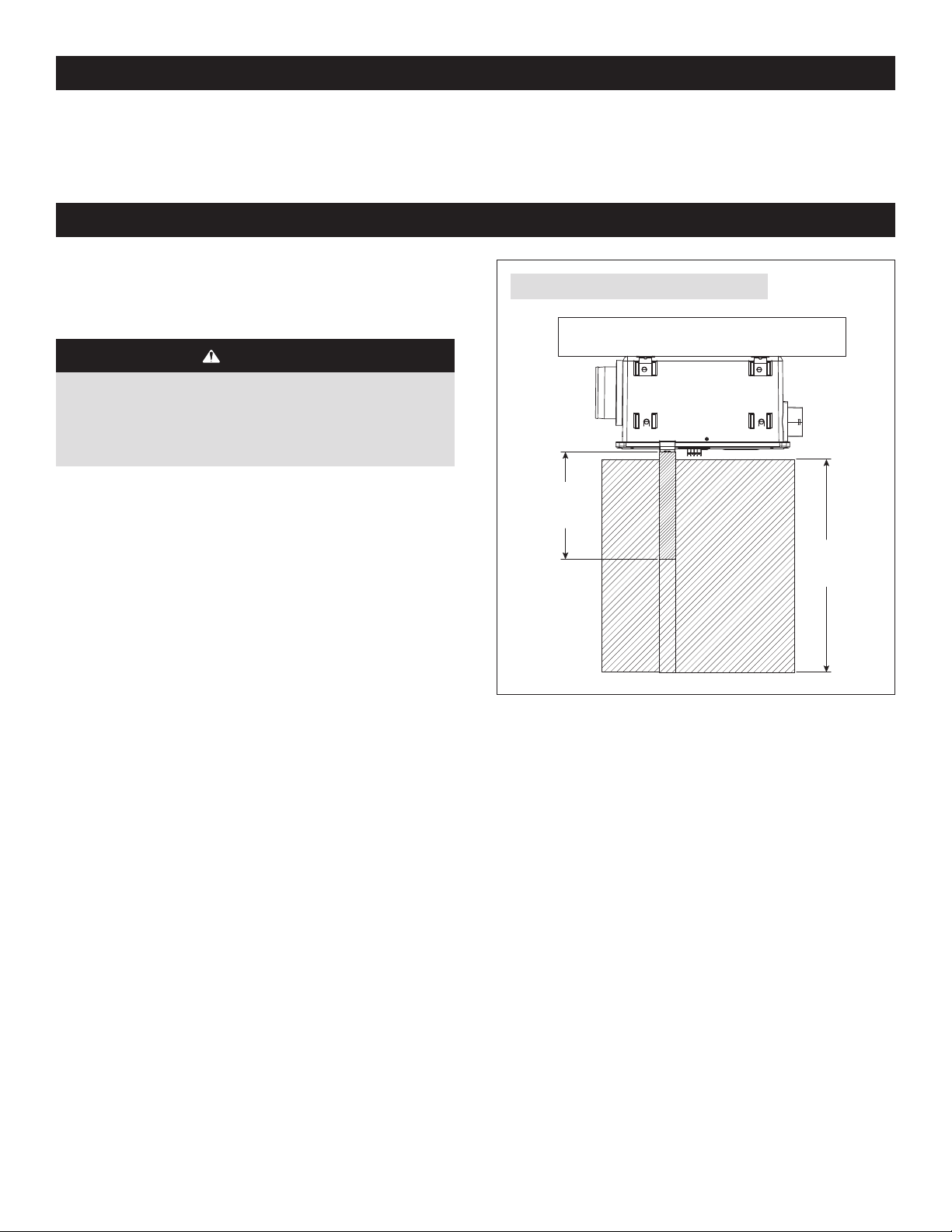

Ventilator Location and Orientation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Mount the Ventilator � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Mount Intake Hood � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Install Ductwork � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

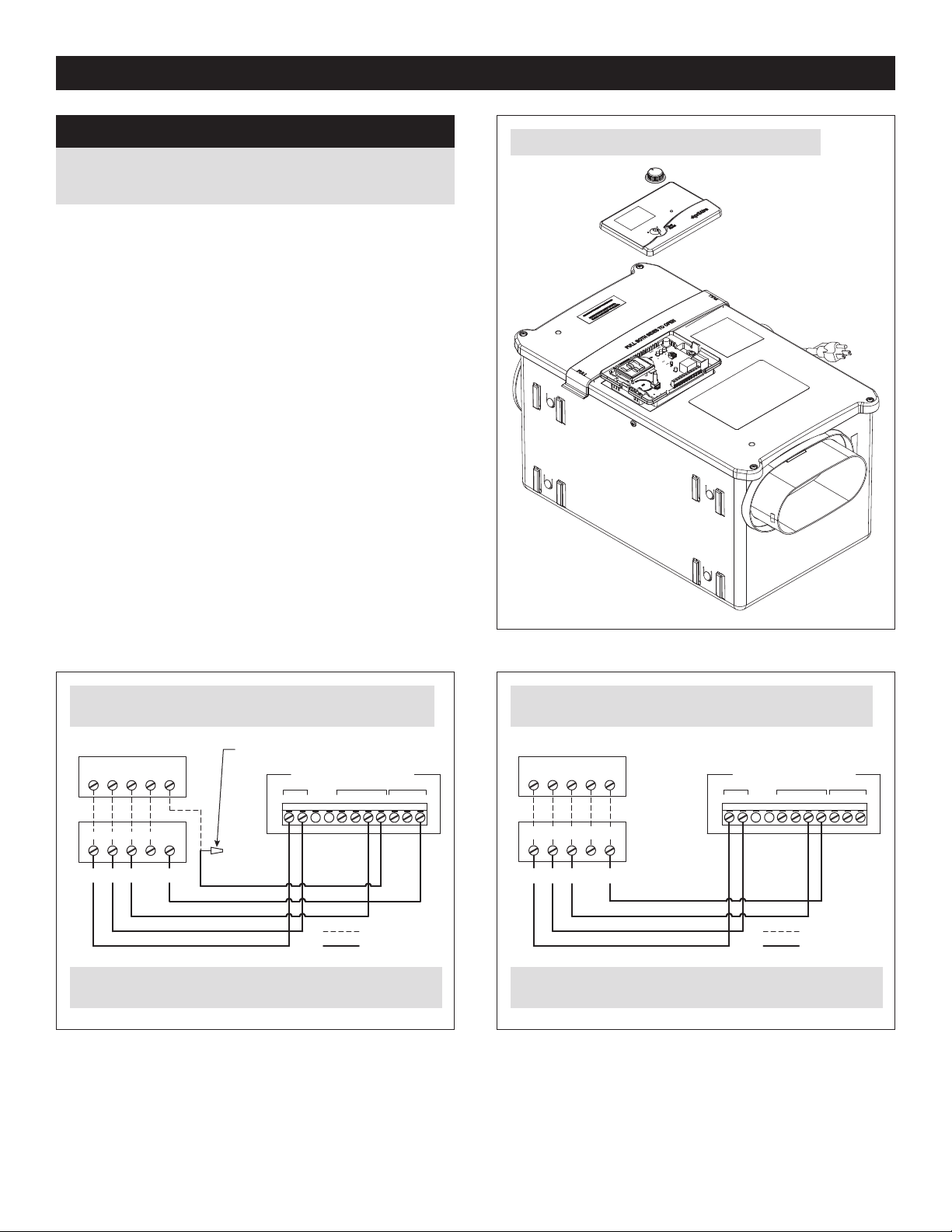

Wiring the Control to the HVAC System � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

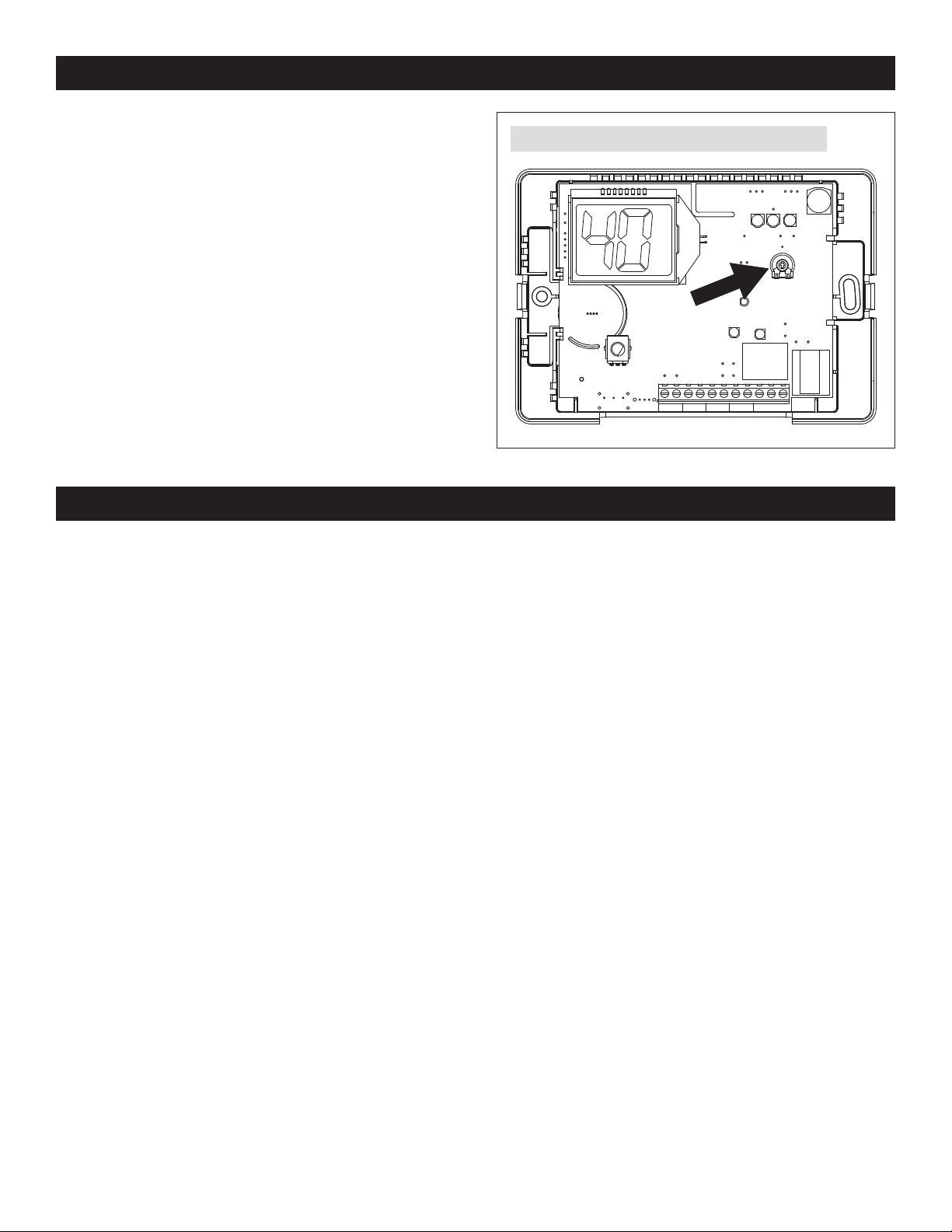

Set Up � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Test� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Measure Delivered Airow � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Determine Ventilation Time Setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

Start Up and Sequence of Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

Filter Cleaning � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

Internal Schematics� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

Limited Warranty � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12