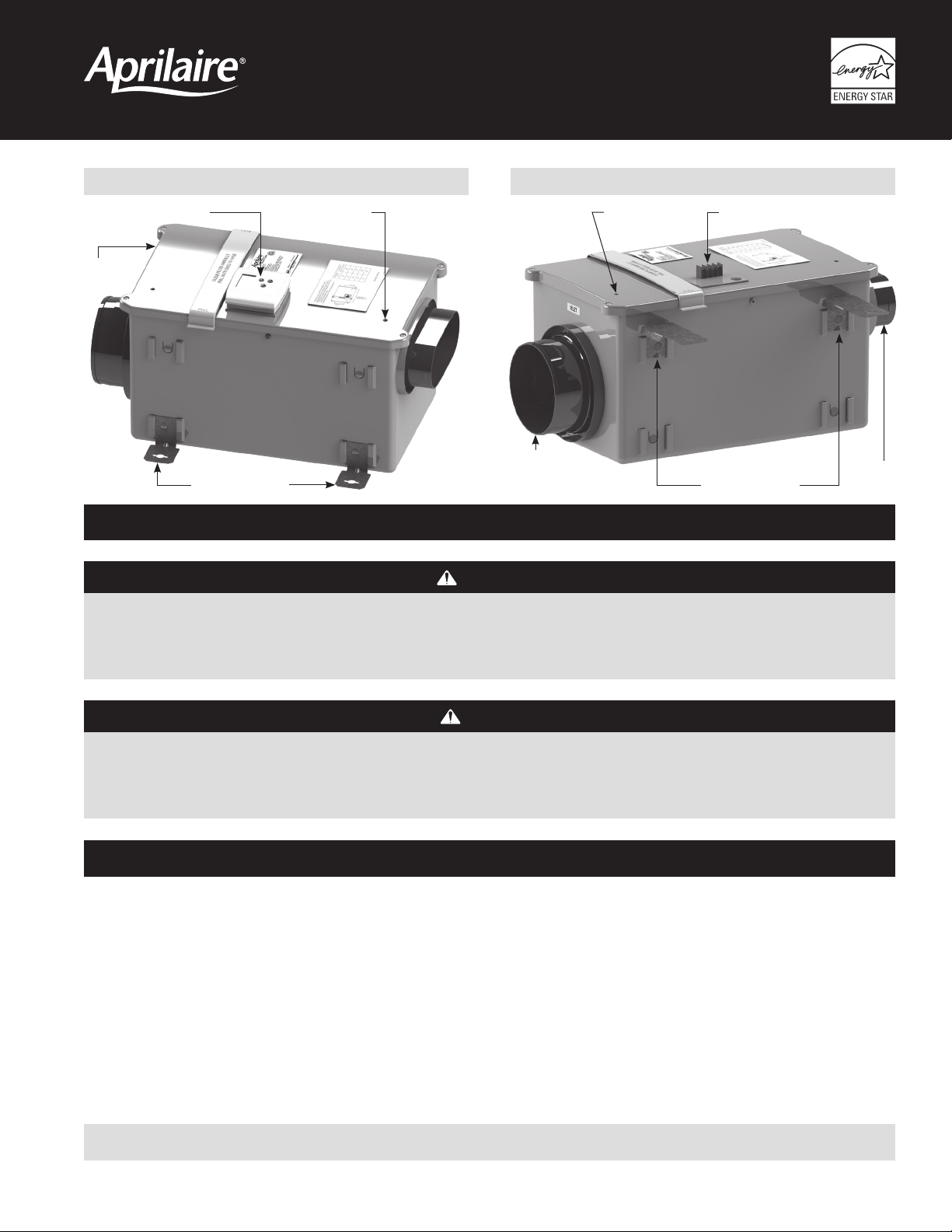

MODEL 8145 – SET UP

NOTICE

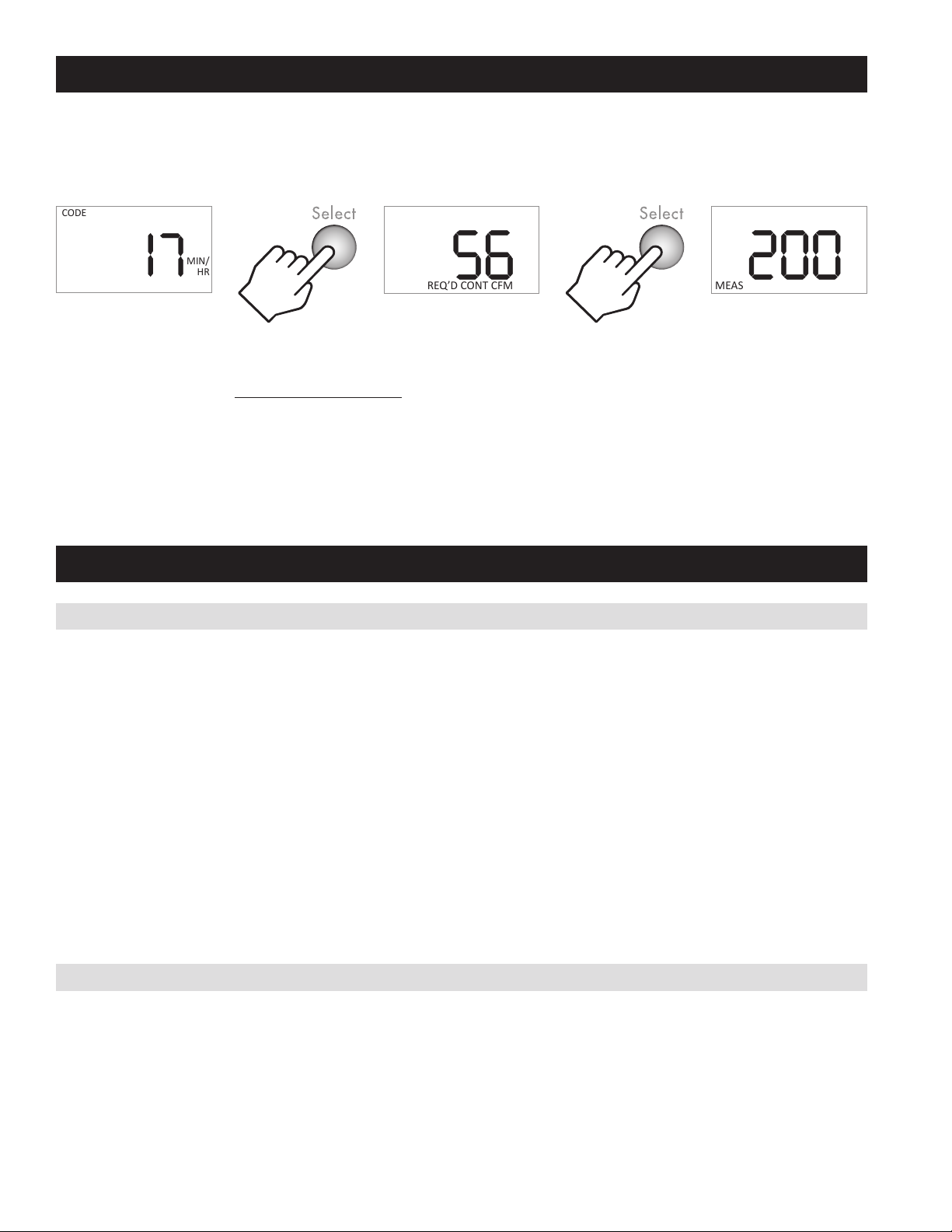

Before setting up the control for use, the amount of ventilation air being delivered (CFM) by the installed ventilation system must be measured.

Hold for 5 seconds, then release.

Throughout the Set Up Menu, the and buttons are used to change values, the Select button is used enter the value and move on to the next Set

Up Menu item.

TABLE 4 – MODEL 8145 SET UP MENU

Menu Item Values Description

HP or HC HP if wiring to a heat pump.

HC if wiring to furnace and AC.

1 – 10

Number of bedrooms –

used to calculate required

continuous ventilation rate.

LOW

500 – 7500 ft2

Square footage – used to

calculate required continuous

ventilation rate.

30 – 250 CFM Measured outdoor airflow

delivered during ventilation.

OFF,

85°F – 105°F

Ventilation high temperature

limit. Ventilation is limited

when the outdoor temperature

exceeds the setting. Turn OFF if

no high limit is desired.

OFF,

-10°F – 40°F

Ventilation low temperature

limit. Ventilation is limited

when the outdoor temperature

falls below the setting. Turn

OFF if no low limit is desired.

On, “bLnd”, OFF

ON HVAC fan turns on

whenever ventilation occurs.

bLnd (blend) HVAC fan turns

on with ventilation only when

the outdoor temperature is

outside a set range.

OFF HVAC fan is not turned on

with ventilation.

TABLE 4 – MODEL 8145 SET UP MENU

Menu Item Values Description

OFF, 60°F to 5°F

less than Vent.

High Temp. Limit

Only available when bLnd is

selected. When the outdoor

temperature is above the

setting, the HVAC fan will

be turned on to mix (blend)

outdoor air with indoor air for

tempering.

OFF, 5°F less

than Vent. Low

Temp. Limit to

55°F

Only available when bLnd is

selected. When the outdoor

temperature is below the

setting, the HVAC fan will

be turned on to mix (blend)

outdoor air with indoor air for

tempering.

See IMPORTANT

NOTE below.

“codE”, “cFrt”

codE No RH limits and any

missed ventilation due to

temperature is made up per

ASHRAE 62.2-2010.

cFrt (comfort) Adds indoor RH

limits to ventilation; ventilation

missed due to limits is not

made up.

OFF,

45% – 70% RH

Only available when cFrt is

selected. When the outdoor RH

exceeds the setting, ventilation

will not occur.

OFF,

10% – 30% RH

Only available when cFrt is

selected. When the outdoor

RH drops below the setting,

ventilation will not occur.

When all Set Up Menu options have been entered, the control will

display donE.

IMPORTANT NOTE: The 8145 control senses the temperature and humidity of the outdoor air. To prevent extended periods of inactivity, set the

control mode to codE, or if setting to cFrt (comfort), set the RH limits to OFF.

English 9