Page 7

Where Unit Can Be Installed

The HEPA-FLOW™APS625 is a mobile floor unit. Please see "Equipment Options" in the

Appendix for accessories required in specific applications.

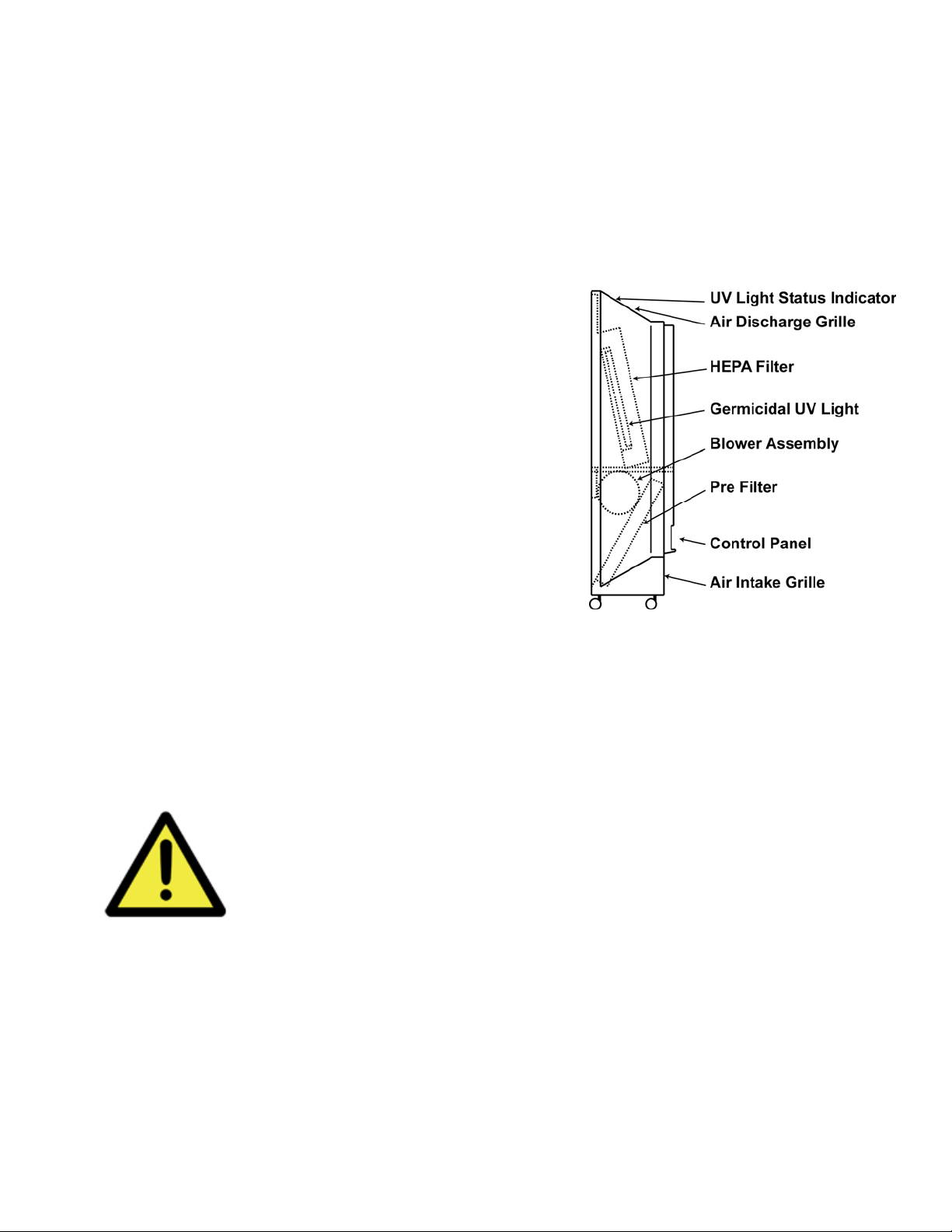

How the Unit Filters and Purifies the Air

The HEPA-FLOW™ APS625 draws room air in through a return air grille at the bottom and

discharges filtered air (supply air) through a grille at the top. This airflow direction cleans the

room air of dust, dirt, and other particles by pulling them down, out of the air and provides

cleaned air at the breathing zone.

As air enters the bottom of the unit, it passes through a

protective grille that prevents objects(pieces of paper,

etc.) from entering the unit and helps assure safety. The

air then passes through a 30% efficient, ASHRAE

antimicrobial filter. This disposable filter, called the pre-

filter, prolongs the life of the finer HEPA filter by

removing large particles from the incoming air.

A blower then forces the air into the unit's upper

chamber, where it is exposed to germicidal ultraviolet

light (253.7nm). Trapped on the inlet side of the HEPA

filter, viable microorganisms are continuously exposed

to this UV radiation, which changes the DNA structure

of the particles and renders them harmless.

Finally, the air passes through the HEPA filter, which is 99.97% efficient in capturing particles

0.3 microns or larger. Particles this size—10,000 times smaller than a human hair and 2,500

times too small to be seen by the unaided human eye—include pollens, lung damaging dust,

bacteria, viruses, and tobacco smoke.

The HEPA filter is firmly sealed to prevent air from leaking around it, assuring that all

processed air has been both radiated and filtered. The sterilized air exits into the room through

the discharge grille at the top of the unit providing cleaned air at the breathing zone.

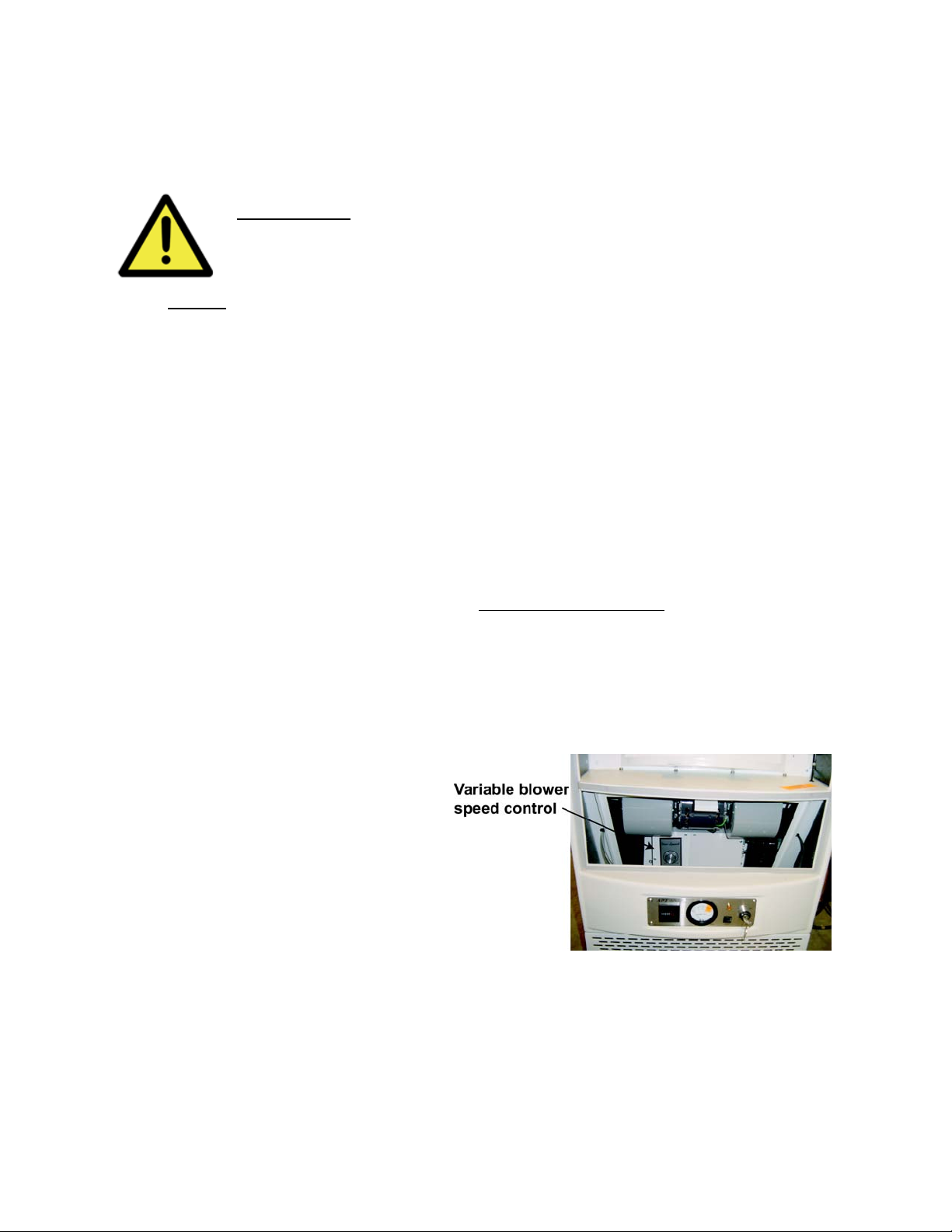

Important

Although the HEPA-FLOW™ APS625 is an effective means of reducing

airborne contaminants; it is to be used in conjunction with standard

universal precautions, such as the use of facial respirators, gloves,

gowns, and other protective measures.