1Version:1.4

TABLE OF CONTENTS

1.0 Introduction..................................................................................................2

2.0 Installation................................................................................................... 3

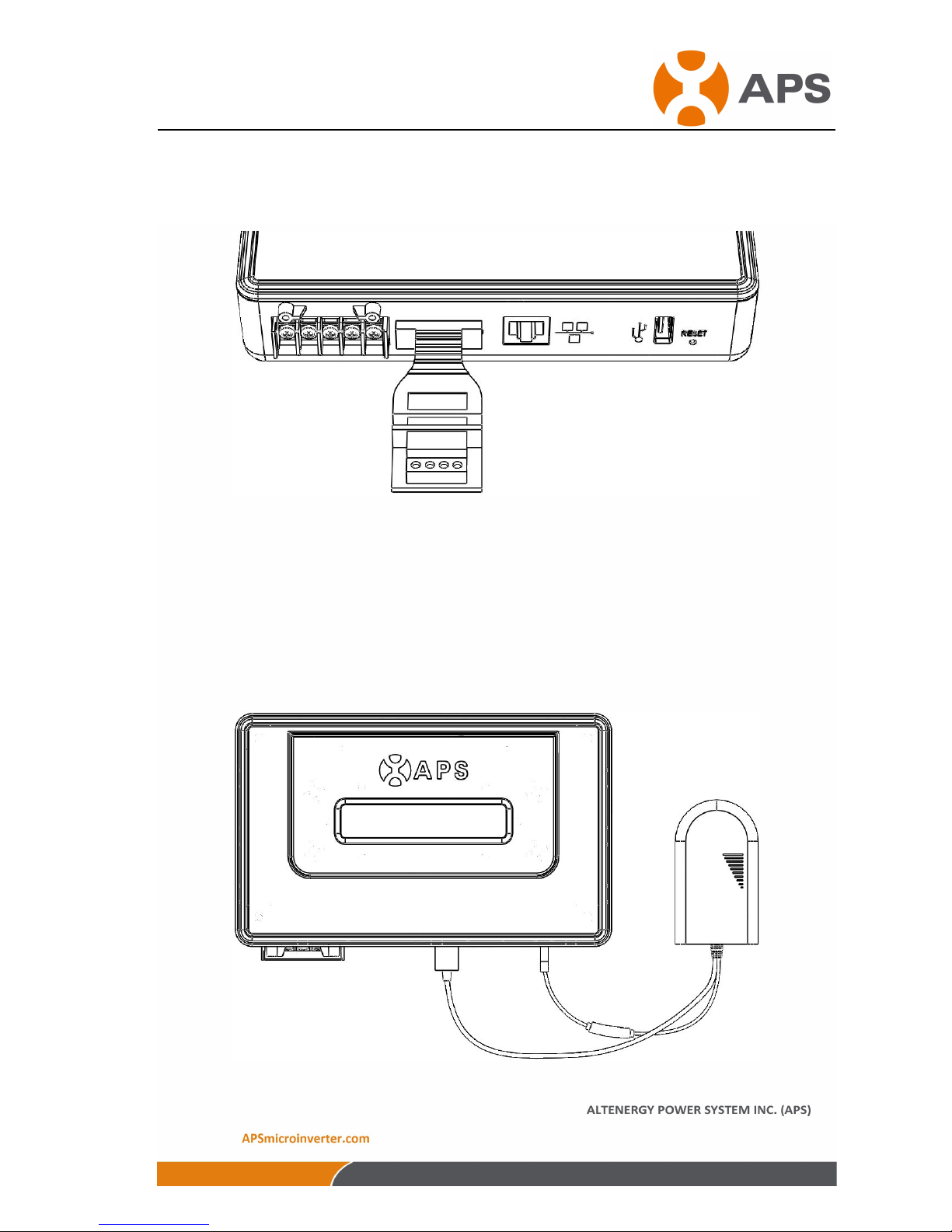

3.0 Interface Explanation...................................................................................8

3.1 Interface position................................................................................. 8

3.2 Power Interface....................................................................................8

3.3 RS232 Serial Port................................................................................ 8

3.4 Network Port........................................................................................9

3.5 USB Interface.................................................................................... 10

3.6 RESET............................................................................................... 10

4.0 Basic Operation......................................................................................... 10

4.1 Power Up........................................................................................... 10

4.2 Menu Structure.................................................................................. 11

4.3 Restore the factory set operation....................................................... 13

4.4 Troubleshooting................................................................................. 13

5.0 ECU Local Interface..................................................................................14

5.1 Home Screen......................................................................................14

5.2 Real-time Data Screen.......................................................................14

5.3 Configuration.....................................................................................15

5.4 Administration Screen....................................................................... 16

6.0 Technical Data........................................................................................... 22