2

TABLE OF CONTENTS

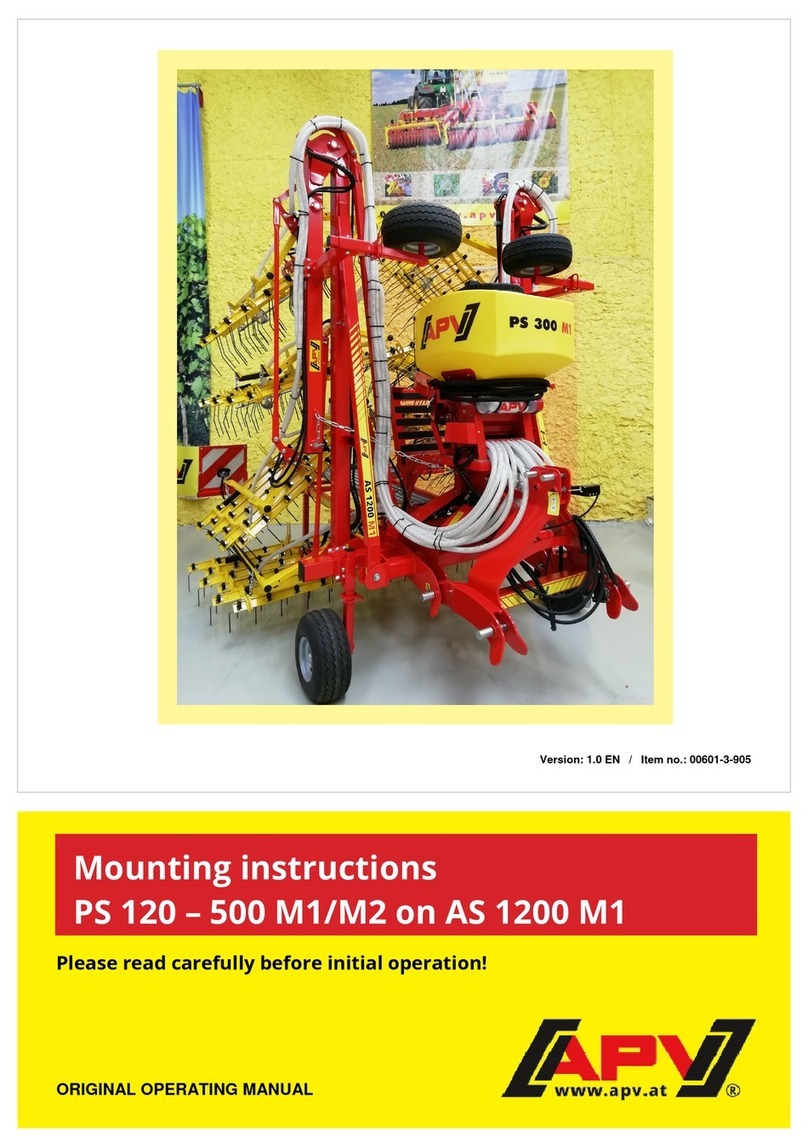

1GENERAL.......................................................................................................................................4

1.1 About this operating manual.................................................................................................4

1.2 Identification of the implement..............................................................................................4

1.3 Service.................................................................................................................................5

1.4 EC Declaration of Conformity...............................................................................................5

2DESCRIPTION................................................................................................................................6

2.1 Layout and functioning of the seed drill................................................................................6

2.2 Layout and function of the hydraulic fan (HG 300 M1) .........................................................7

2.3 Scope of delivery .................................................................................................................8

2.4 Technical data .....................................................................................................................8

3SAFETY..........................................................................................................................................9

3.1 Safety instructions in this document.....................................................................................9

3.2 Basic safety regulations.....................................................................................................10

3.3 Intended use......................................................................................................................11

3.4 Personnel requirements.....................................................................................................11

3.5 Personal protective equipment...........................................................................................11

3.6 Safety devices ...................................................................................................................12

3.7 Dangers and safety measures ...........................................................................................13

4TRANSPORT, INSTALLATION AND COMMISSIONING.............................................................15

4.1 Attaching the seed drill to a soil tillage implement..............................................................15

4.2 Attaching the seed drill to a tractor.....................................................................................16

4.3 Installing the dispersion plates on the soil tillage implement...............................................17

4.4 Connecting the hoses........................................................................................................18

4.5 Removing the swell air plate ..............................................................................................19

4.6 Connecting the hydraulic fan (HF)......................................................................................20

4.7 Connecting the electric fan PLUS ......................................................................................21

5OPERATION.................................................................................................................................22

5.1 Setting the hydraulic fan (HF).............................................................................................22

5.2 Setting and adjusting the spread rate.................................................................................24

5.3 Regulating the seed flow rate (calibration test)...................................................................24

5.4 Selecting the right seeding shaft........................................................................................25

5.5 Changing the seeding shaft ...............................................................................................26

5.6 Checking the ease of motion of the seeding shaft..............................................................28

5.7 Setting the brush pressure.................................................................................................29

5.8 Filling the seed hopper.......................................................................................................29

5.9 Deactivating the agitator ....................................................................................................30

5.10 Display on the motor module..............................................................................................31

6FAULT INDICATIONS ..................................................................................................................32

6.1 Fault overview....................................................................................................................32

7CLEANING, MAINTENANCE, AND REPAIRS.............................................................................33

7.1 Disconnecting the seed drill from the power supply............................................................33

7.2 Emptying the seed hopper.................................................................................................34

7.3 Cleaning the seed drill........................................................................................................34

7.4 Checking the hydraulic hoses ............................................................................................35

7.5 Repairs and service...........................................................................................................35