CONVERSION

!

!

!

Instructions are for conversion from Natural Gas to Propane (L.P.) on all models GCRB and GCB.

The conversion should be done before connecting the unit to the gas supply.

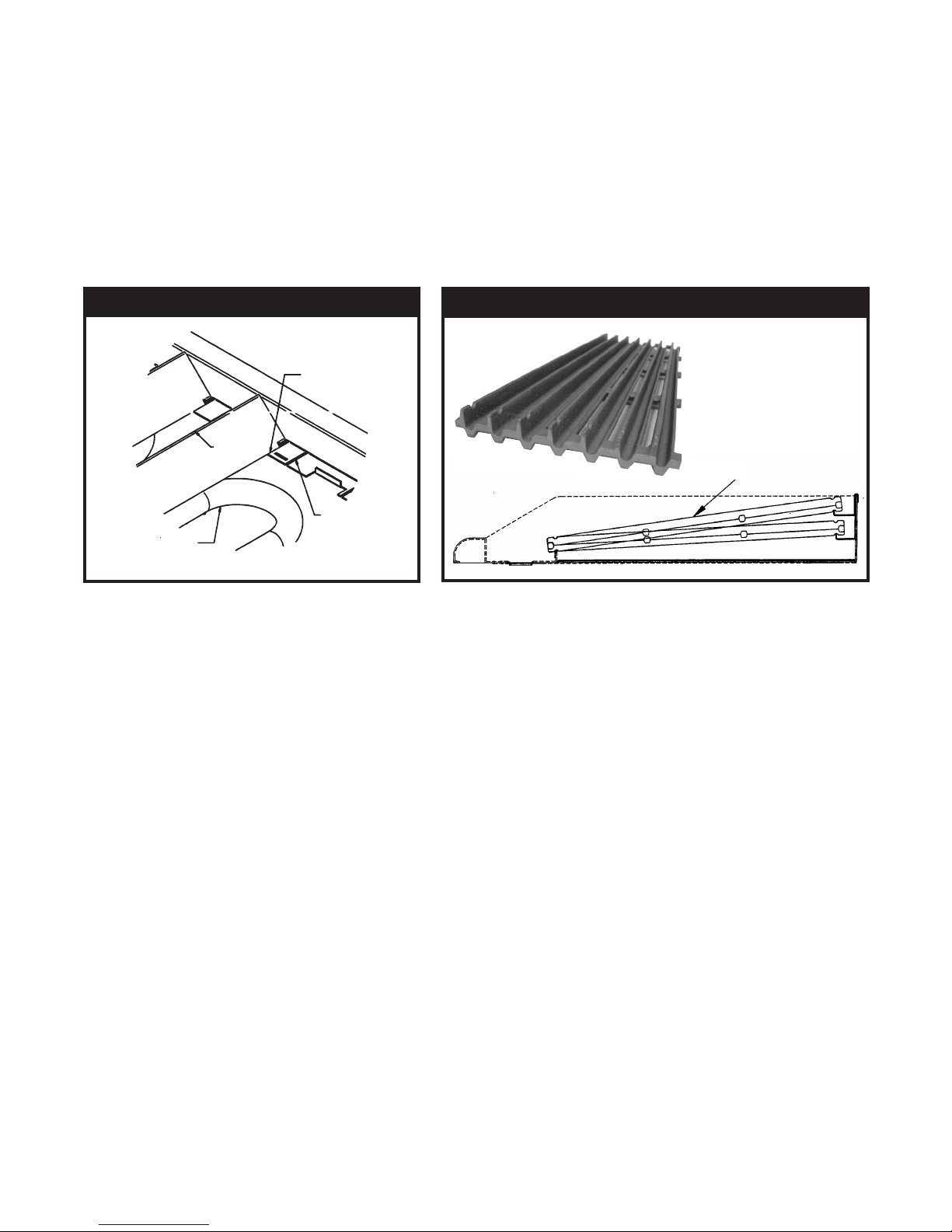

1. Remove the knobs and front panel.

2. Remove the orifice fittings from the valve. Change the orifices to the size recommended for propane

(L.P.).

3. Replace the orifice fittings into the valve.

4. Remove cap, invert the insert and replace cap. Marking on insert.

5. Continue with the installation.

Units are shipped from the factory equipped for use on natural gas. Orifices necessary for LP

(propane) are provided in a bag tied to the valve on the front panel.

NOTE:

LIGHTING INSTRUCTIONS

GCB and GCRB Broilers are furnished with either a pilot safety valve or a standing pilot (not available in the

European Community). Please follow the instructions for your unit.

Lighting instructions are on the right side panel.

If the pilot goes out, an automatic shutoff valve turns off the gas supply to the burners. To relight the pilot,

follow this procedure:

Turn the control valve to "OFF". Wait a sufficient length of time to allow gas, which may have

accumulated in the burner compartment, to escape (at least five minutes).

Turn on the main shutoff valve.

Depress and hold in the red button "A" on the automatic shutoff valve while lighting the pilot burner.

When gas at pilot has been burning for about 45 seconds, release the red button. If pilot does not

remain lit, repeat the operation, allowing more time before releasing red reset button. The button

can be accessed through an opening in the front panel.

To adjust the pilot flame, Rotate the knob clockwise to reduce the gas flow, and counterclockwise to

increase the gas flow; to provide a properly sized pilot flame (approximately 1/2" to 3/4" long). (12 to

19 mm)

All units are equipped with fixed orifices for use with natural gas, and no adjustment is necessary.

Units for operation on natural or propane gas, are also equipped with a factory preset pressure

regulator with an outlet pressure of 6.0" W.C. (15 'mbar') for natural gas supply, and 10" W.C. (25

'mbar') for propane gas supply, and should not require further adjustment.

( NotAvailable in the European Community )

The pilot lights on the broilers have been set at the factory. A screwdriver may be required for the first

lighting to adjust the flame for your elevation.

1 Turn off the manual shut off valve and wait 5 minutes to clear the gas.

2 Turn all knobs to the "OFF" position.

3 The valve can be accessed through an opening in the front panel.

4 Turn the manual shut off valve on.

5 Hold an ignition source (match) at the pilot tube. When the flame is established, remove the ignition

source.

6 Turn the burner knobs to "HI". If the burner does not ignite, promptly open the pilot valve more. If the

pilot flame appears larger than necessary, turn it down and reset burner ignition. The pilot flame

should be as small as possible but large enough to guarantee reliable ignition of the burners when

the knobs are turned to "HI".

If the pilot light should go out for any reason:

Promptly shut off all gas at the manual shut off valve.

Turn off all knobs and pilot valves; wait 5 minutes to clear gas.

Pilot Safety Valve Lighting Instructions:

Standing Pilot Lighting Instructions:

RELIGHTING PILOT

!

!

!

!

!

!

!

!

!

7