GENERAL INSTALLATION INSTRUCTIONS

Ensure gas supply and gas type, as shown on unit nameplate agree.

Unit installation must conform with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, the National Gas

Installation Code, CSA-B149.1, or the Propane Installation Code, CSA-B149.2 as applicable and in

accordance with local codes.

Screw legs into the permanently fastened nuts on the four corners of the unit and tighten by hand. Level the

unit by turning the adjustment screw at the bottom of each leg. Do not slide unit with legs mounted, lift if

necessary to move unit.

Pipe threading compound must be resistant to the action of liquefied petroleum gases.

Caution: DO NOT use an open flame to check for leaks. Check all gas piping for leaks with a soap and water

solution before operating unit.

THESE UNITS ARE SUITABLE FOR INSTALLATION ON NON-COMBUSTIBLE SURFACES ONLY.

Noncombustible clearances:

0" sides (0 mm) 0" rear (0 mm) 4” floor (102mm)

Do not obstruct the flow of combustion and ventilation air, under the unit by the legs or behind the unit by the

flue.

Adequate clearance for air openings into the combustion chamber is required. Do not place objects between

the bottom of the unit and the counter top.

There must be adequate clearance for removal of the front panel. All major parts except the burners are

removable thru the front if the gas line is disconnected.

Unit must have adequate clearances for servicing. (Sides = 0”, Rear = 0”, Floor = 4”).

European Community Installation Instructions:

“THIS APPLIANCE MUST BE FITTED BY A COMPETENT PERSON. IN THE UK, CORGI REGISTERED

INSTALLERS (INCLUDING THE REGIONS OF BRITISH GAS) UNDERTAKE TO WORK TO SAFE AND

SATISFACTORY STANDARDS. THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE

GAS SAFETY (INSTALLATION AND USE) REGULATIONS AND THE RELEVANT BUILDING

REGULATIONS / IEE. REGULATIONS. DETAILED RECOMMENDATIONS ARE CONTAINED IN THE

FOLLOWING BRITISH STANDARD CODES OF PRACTICE - BS 6172, BS 5440 PART 2, BS 6891"

"THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE RULES IN FORCE”

"MUST BE INSTALLED IN A WELL VENTILATED AREA. Ventilation requirements ie. B.S. 5440.”

4

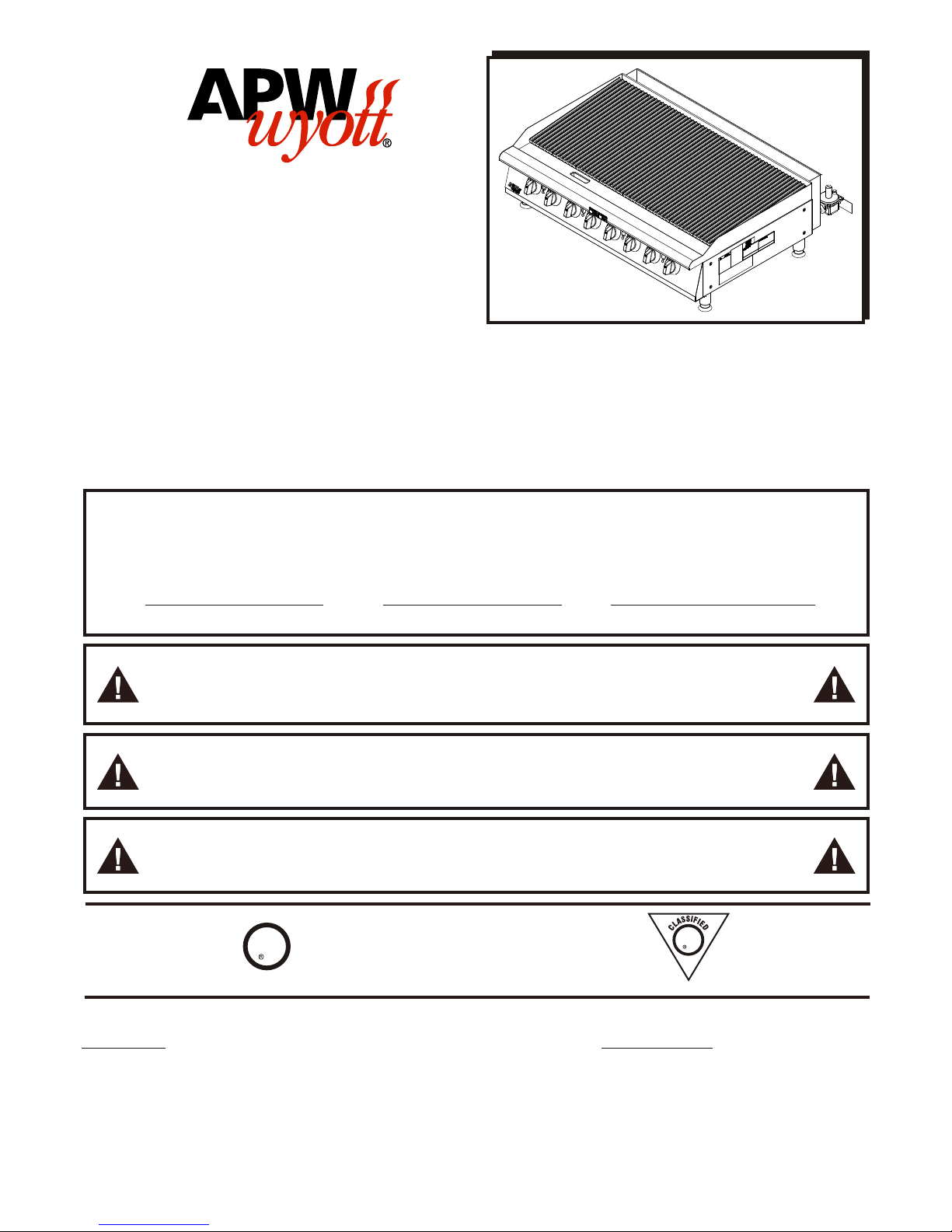

SPECIFICATIONS AND DIMENSIONS

MODEL WIDTH

IN. (MM)

DEPTH

IN. (MM)

HEIGHT

IN. (MM)

# OF

BURNERS

BTU/kW PER

BURNER

NATURAL GAS

TOTAL

BTU/kW HOUR

W.C.

IN. (’Mbar’)

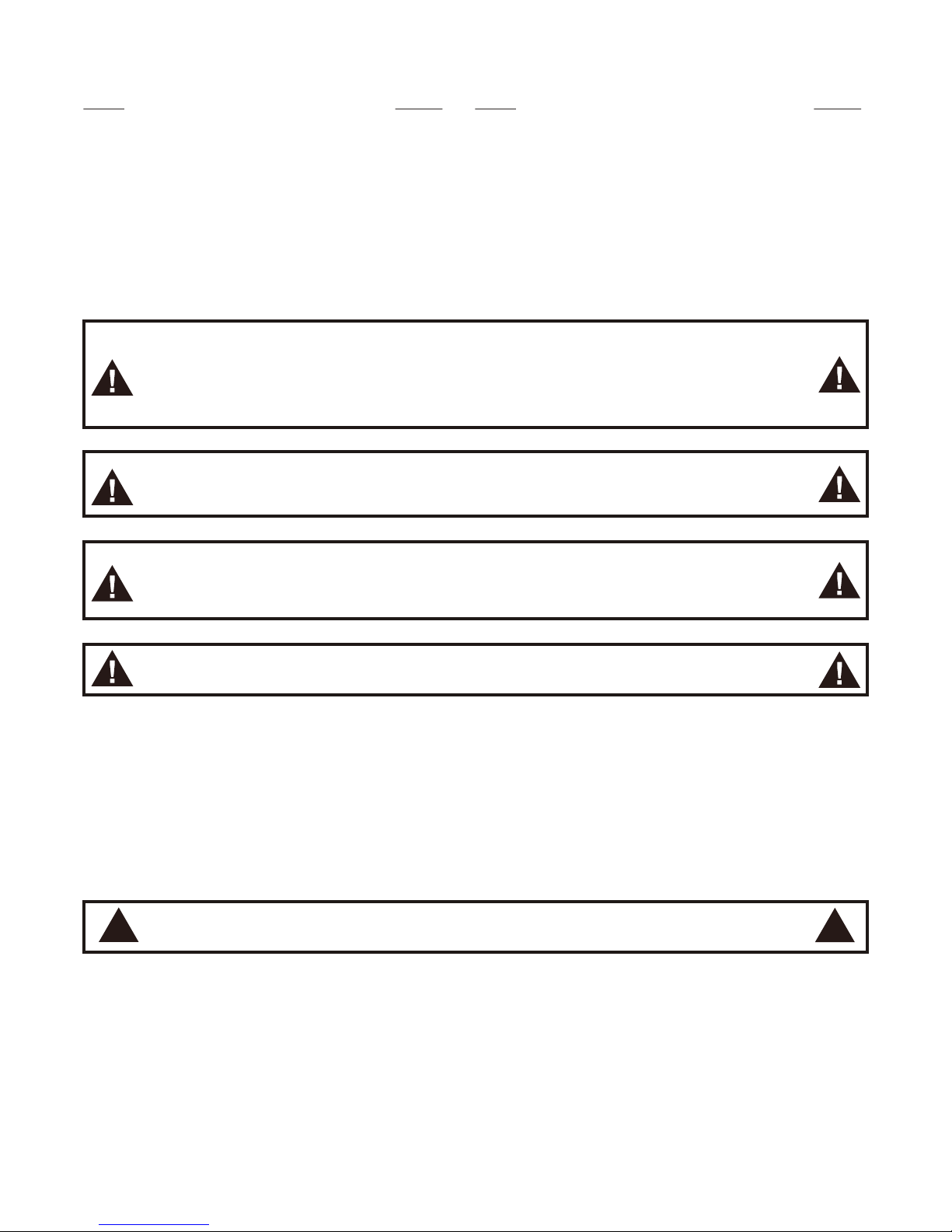

HCB-2424 24" (609.6) 34.339” (872.2) 15.217" (386.5) 4 20,000 (5.86) 80,000 (23.4) 5 (12.4)

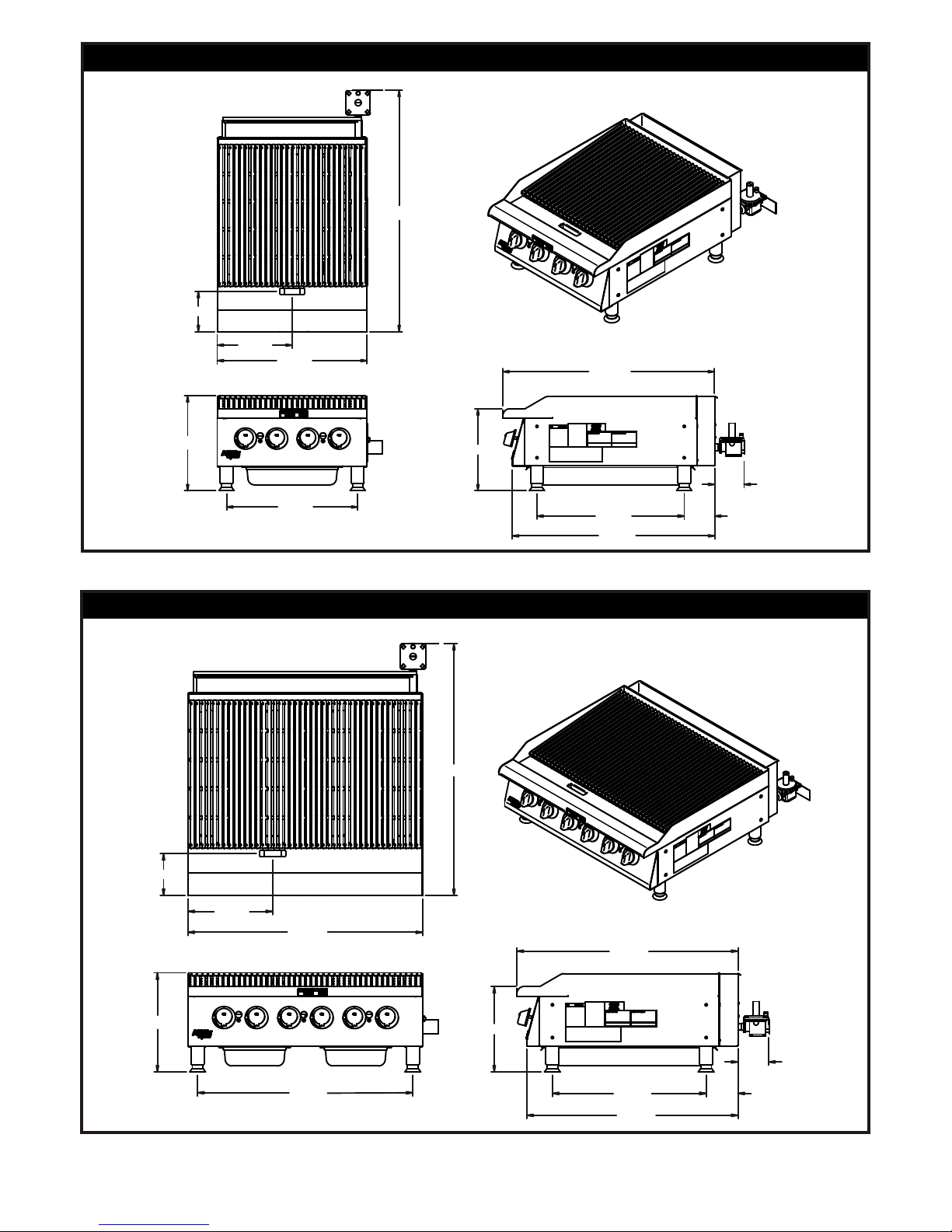

HCB-2436 36" (914.4) 34.339” (872.2) 15.217" (386.5) 6 20,000 (5.86) 120,000 (35.2) 5 (12.4)

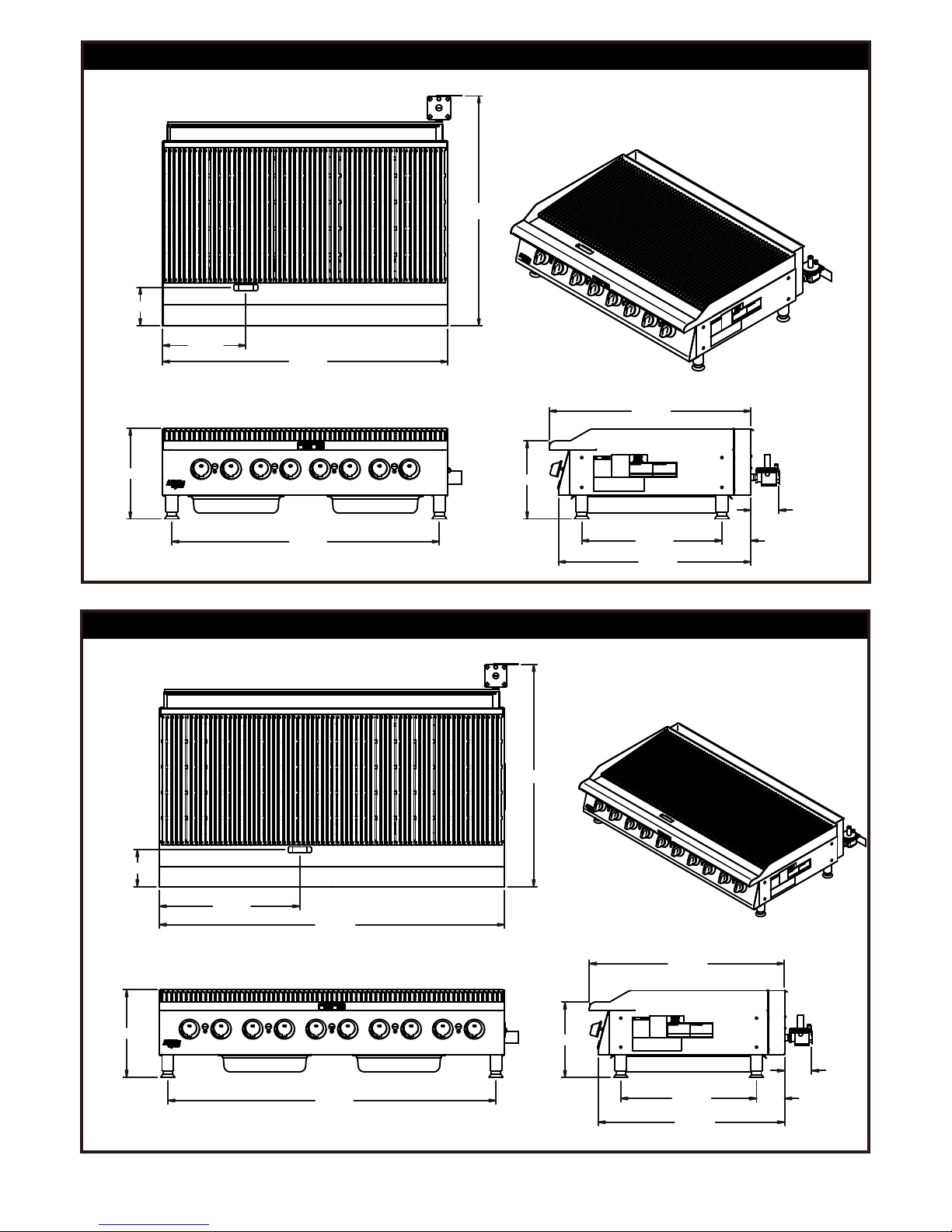

HCB-2448 48" (1219.2) 34.339” (872.2) 15.217" (386.5) 8 20,000 (5.86) 160,000 (46.9) 5 (12.4)

HCB-2460 60" (1524.0) 34.339” (872.2) 15.217" (386.5) 10 20,000 (5.86) 200,000 (58.6) 5 (12.4)

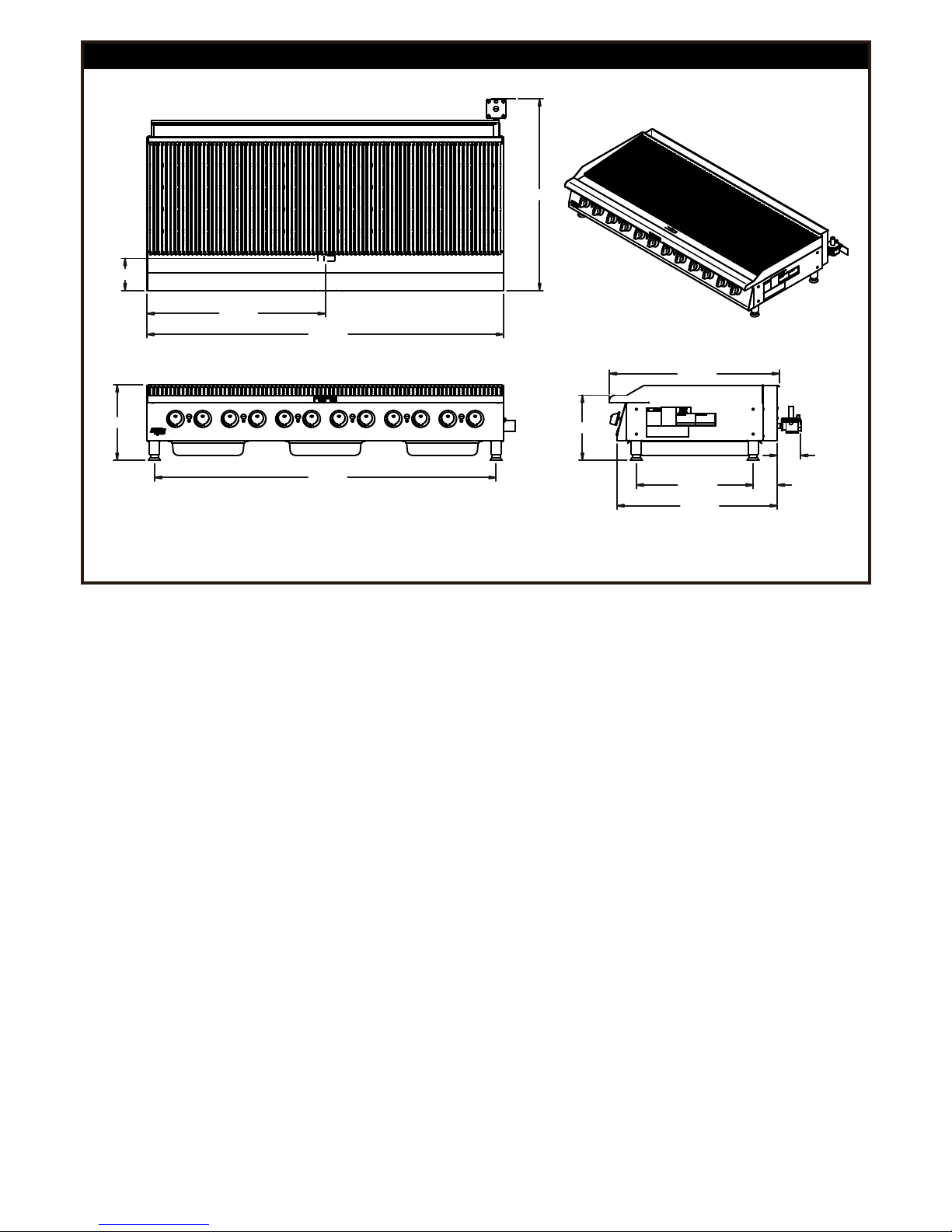

HCB-2472 72" (1828.8) 34.339” (872.2) 15.217" (386.5) 12 20,000 (5.86) 240,000 (70.3) 5 (12.4)

HCRB-2424 24" (609.6) 34.339” (872.2) 15.217" (386.5) 4 20,000 (5.86) 80,000 (23.4) 5 (12.4)

HCRB-2436 36" (914.4) 34.339” (872.2) 15.217" (386.5) 6 20,000 (5.86) 120,000 (35.2) 5 (12.4)

HCRB-2448 48" (1219.2) 34.339” (872.2) 15.217" (386.5) 8 20,000 (5.86) 160,000 (46.9) 5 (12.4)

HCRB-2460 60" (1524.0) 34.339” (872.2) 15.217" (386.5) 10 20,000 (5.86) 200,000 (58.6) 5 (12.4)

HCRB-2472 72" (1828.8) 34.339” (872.2) 15.217" (386.5) 12 20,000 (5.86) 240,000 (70.3) 5 (12.4)