3

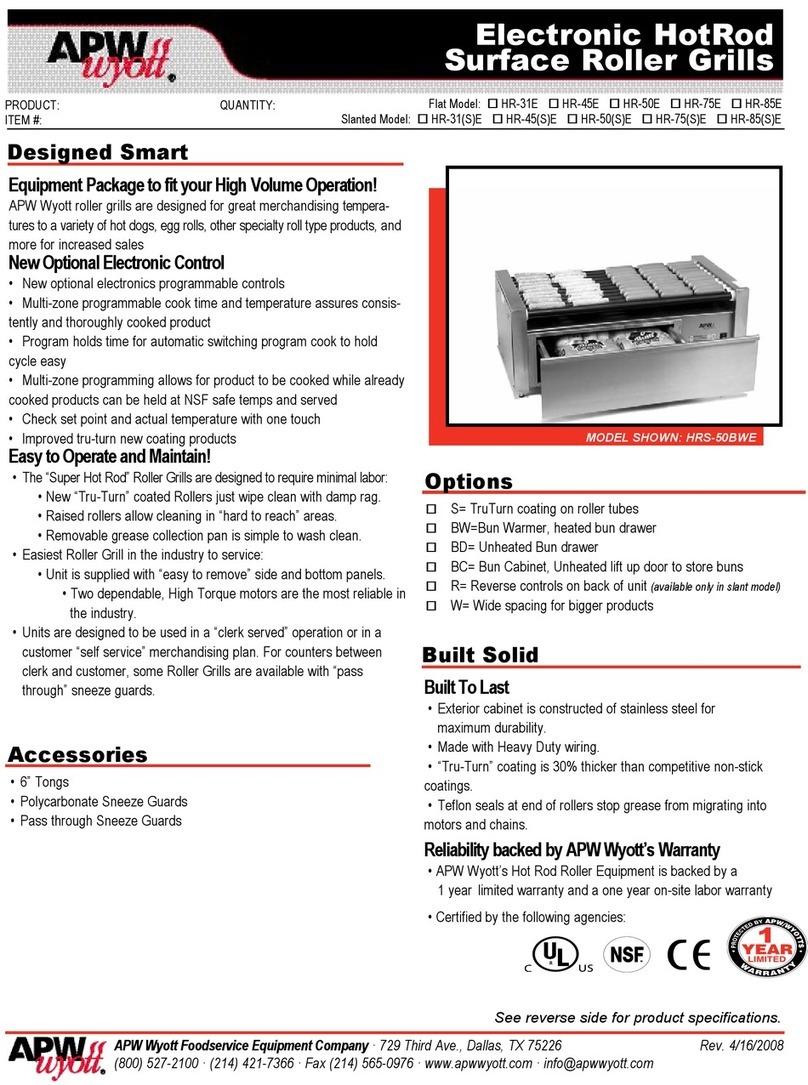

CAUTION: These models are designed, built, and sold for commercial use. If these

models are positioned so the general public can use the equipment make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so

that anyone using the equipment will use it correctly and not injure themselves or

harm the equipment.

NOTICE: The unit when installed, must be electrically grounded and comply with

local codes, or in the absence of local codes, with the national electrical code ANSI/

NFPA70- latest edition. Canadian installation must comply with CSA-STANDARD

C.22.2 Number 0 M1982 General Requirements-Canadian Electrical Code Part II,

109-M1981- Commercial Cooking Appliances.

CAUTION: Maintenance & Repair should be handled by a factory authorized agent.

Before doing any maintenance or repair, contact APW Wyott.

WARNING: Disconnect device from electrical power supply and place a Tag Out-

Lockout on the power plug, indicating that you are working on the circuit.

WARNING: Check the data plate on this unit before installation. Connect the unit

only to the voltage and frequency listed on the data plate. Connect only to 1 or 3

phase as listed on the data plate.

NOTICE: Install according to the spacing requirements listed in the installation

section of this manual. We strongly recommend having a competent professional

install this equipment. A licensed electrician should make the electrical connections

and connect power to the unit. Local codes should always be used when

connecting these units to electrical power. In the absence of local codes, use the

latest version of the National Electrical Code.

NOTICE: Local codes regarding installation vary greatly from one area to another.

The National Fire Protection Association, Inc. states in its NFPA96 latest edition that

local codes are “Authority Having Jurisdiction” when it comes to requirement for

installation of equipment. Therefore, installation should comply with all local codes.

Location of Data Plate

The data plate for the Hot Rod is located on the back of the unit.

Immediately Inspect for Shipping Damage

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either

apparent or concealed, a claim must be made with the delivering carrier.

A. Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be

signed by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The

carrier can supply the necessary forms.

B. Concealed damage or loss if not apparent until after equipment is uncrated, a request for

inspection must be made to the carrier within 15 days. The carrier should arrange an inspection.

Be certain to hold all contents and packaging material.

Installation and start-up should be performed by a qualied installer who thoroughly read, understands

and follows these instructions.