Ceiling mounted air ltration units

22

INDEX

1 Introducon ................................................. 3

2 InformaonontheMAXITOPdustcollector ....................... 3

3 Presentaon ................................................. 4

3.1 Each MAXITOP dust collector includes.............................. 4

4 Modelnumbers .............................................. 5

5 Normaluse .................................................. 5

5.1 Start-up with new cartridges...................................... 5

5.2 Normal start-up (with used cartridges) ............................. 5

5.3 Pressuredierenal............................................. 5

6 Operaonandpurpose ........................................ 5

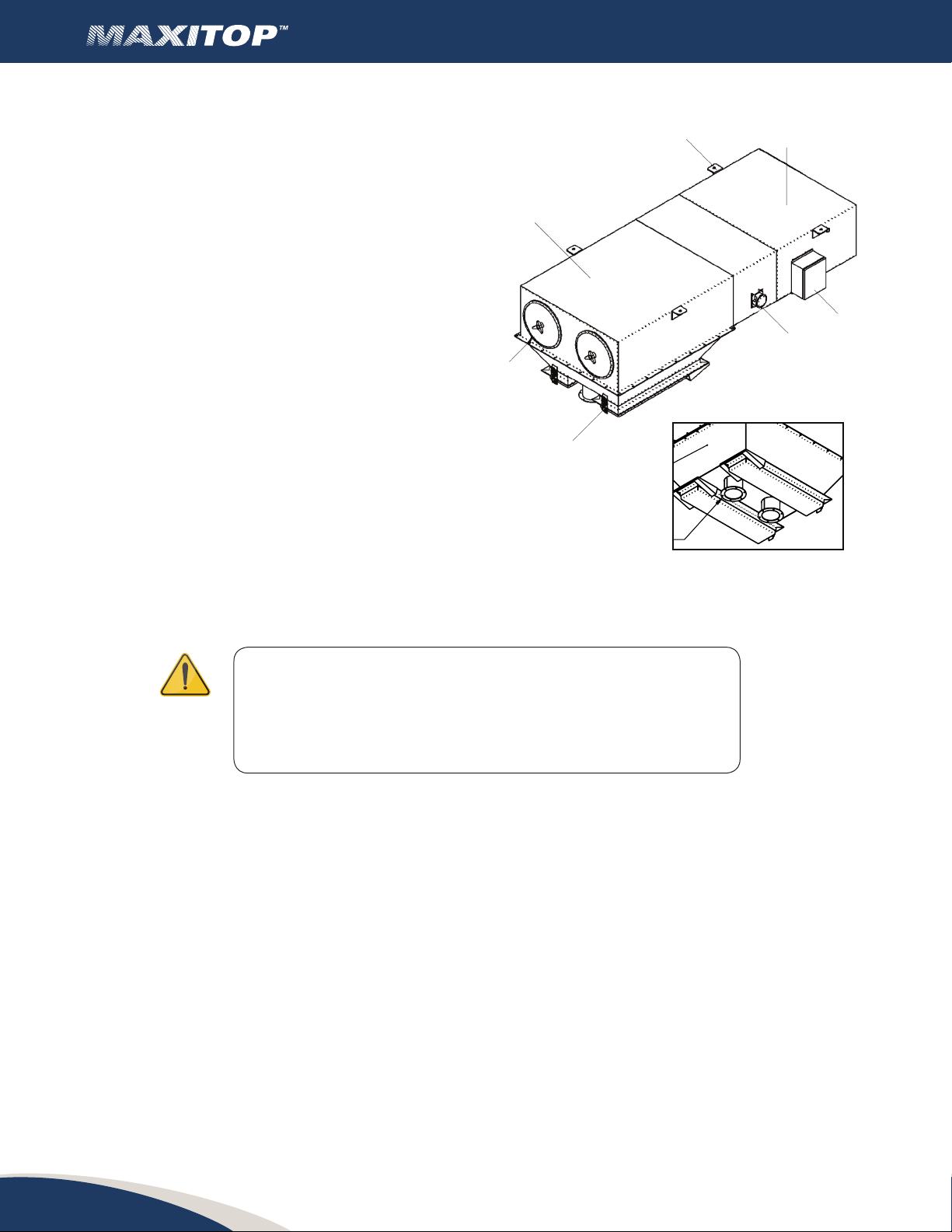

7 Components ................................................. 6

8 Installaon .................................................. 6

8.1 Inspeconofgoods ............................................. 6

8.2 Locaon....................................................... 6

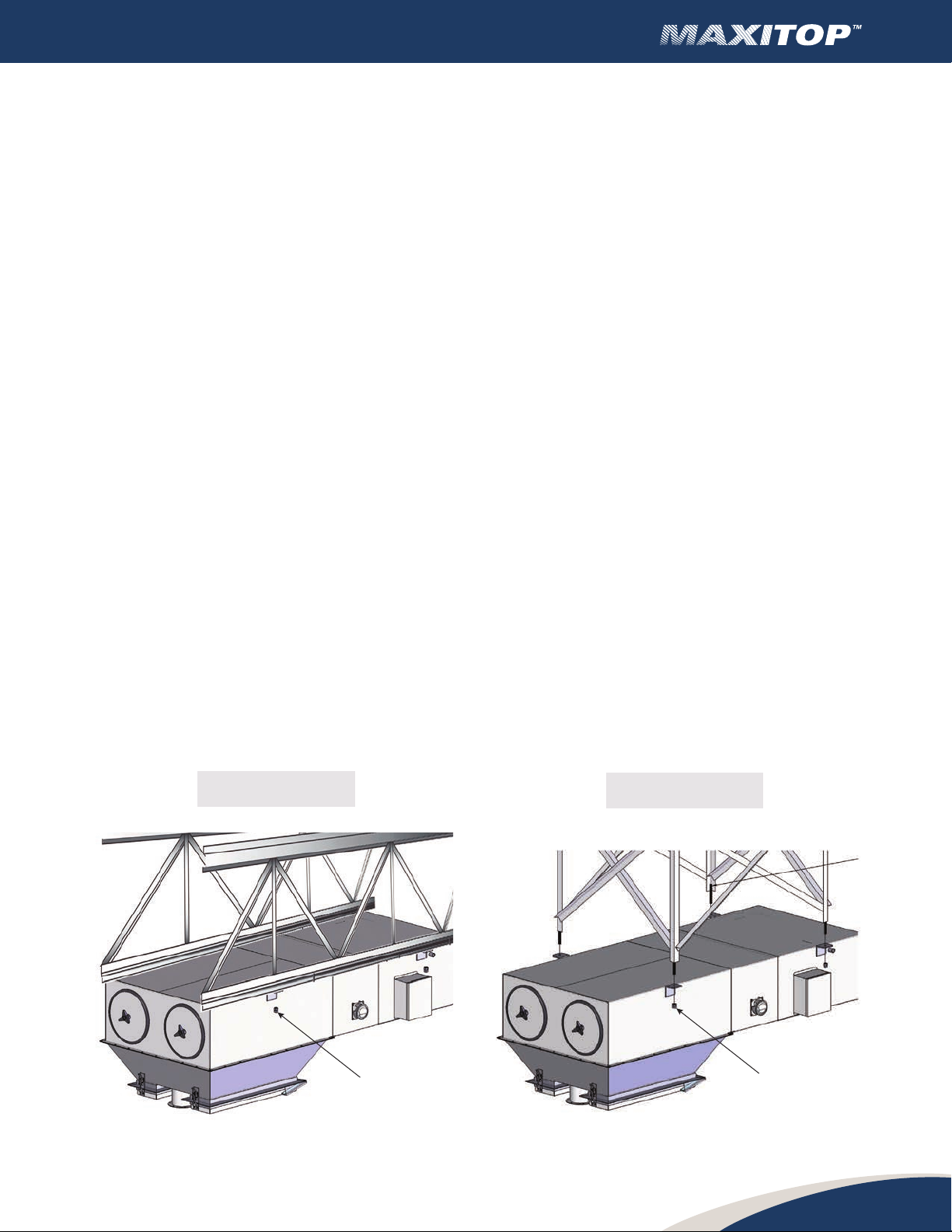

8.3 Installaon .................................................... 7

9 Oponalequipment........................................... 8

10 Electricalconnecon .......................................... 8

10.1 ElectricalconneconforDCT-500sequencer ........................ 8

10.2 DCT-500boardspecicaons ..................................... 9

10.3 ElectricalconneconforDCT-1000sequencer ....................... 10

10.4 DCT-1000boardspecicaons .................................... 10

10.5 Compressedairconnecon....................................... 11

10.6 Electricalconneconscheckandinialstart-up ...................... 11

11 Magnehelicgauge ............................................ 11

12 Shutdown................................................... 12

13 Sparkproducingacvies ...................................... 12

14 Maintenance................................................. 12

14.1 Cartridgereplacement........................................... 12

14.2 Dustdisposal................................................... 13

14.3 Compressedairsystem .......................................... 14

14.4 ProgramminginstruconsDCT-500sequencer....................... 14

14.5 DCT-1000sequencer ............................................ 14

15 Maintenanceandinspecon .................................... 15

16 Troubleshoong .............................................. 17

17 Warranty.................................................... 19

18 Limitaonofliability .......................................... 20

19 Applicability ................................................. 20

20 Governinglaw................................................ 20