drw 875-1500 & 5000

rev1/89, 2/94, 980123, 980902,001217,080816; 090519; 090805PS; 090910PS; 090917PS

OPERATION AND MAINTENANCE

MODEL 873-1500 & -5000 REGULATORS

The model 873 is a

piston type hand loading

regulator. It utilizes a balanced poppet

design for high

flow and minimum effect of inlet pressure on

outlet

pressure. The poppet assembly is contained in a

cartridge with internal

filtration for easy in-field

changing. The regulator is self venting but is

optionally available without the vent.

SPECIFICATIONS

• Maximum inlet pressure

6000PSI (40 MPa)

• Maximum Outlet pressure

873-1500

1500 PSI

873-5000

5000 PSI

• Flow coefficient (C

v

)

0.8

(equivalent to 0.23" orifice)

• Rise of outlet pressure with

drop of inlet pressure

873-1500

35 PSI/1000 PSI

873-5000

110 PSI/1000 PSI

• Materials - body and cap -

aluminum

internals -

brass,stainless,

seals, -

KEL-F, Viton

• Fittings

1/4" FNPT inlet

1/2" FNPT outlet

• Size

3" dia x 6" lg

INSTALLATION

Use a suitable pipe thread sealant such as

Teflon tape

on inlet and

outlet threads. Avoid over torquing pipe

thread. Normal torque applied with a 6 or 8 inch

long

wrench is ample. Use ample Teflon tape - 3 or

4 turns,

not 1 or 2 turns. The inlet is on the left

when facing

the adjusting knob

with the two gage ports upward.

An optional panel mounting nut

is available (part no.

952). This nut permits mounting the regulator

using a

1.25" hole in

a panel or plate. The regulator is NOT

shipped oxygen clean and

should NOT be used for

oxygen service as provided. Consult the factory for

details on oxygen service.

The 1/2" port is the outlet.

The 1/4" port

adjacent to the 1/2" port is the outlet

gauge port. The other two 1/4" ports are the inlet and

inlet

gauge ports. Either of these ports can be used

as the inlet. Connect the inlet to the source gas such

as a high pressure storage tank. The

outlet is capable

of being adjusted from 0

up. AN OUTLET GAUGE

AND RELIEF VALVE SET

NO HIGHER THAN

MAXIMUM OUTLET PRESSURE

SHOULD BE

CONNECTED

TO THE OUTLET. A 1/2" NPT SIZE

RELIEF VALVE

SHOULD BE USED FOR FULL

PROTECTION. IF THE

INLET PRESSURE CAN

EXCEED 6000 PSI A RELIEF

VALVE SHOULD ALSO BE INSTALLED AT THE

INLET TO PREVENT EXCEEDING 6000 PSI.

OPERATION

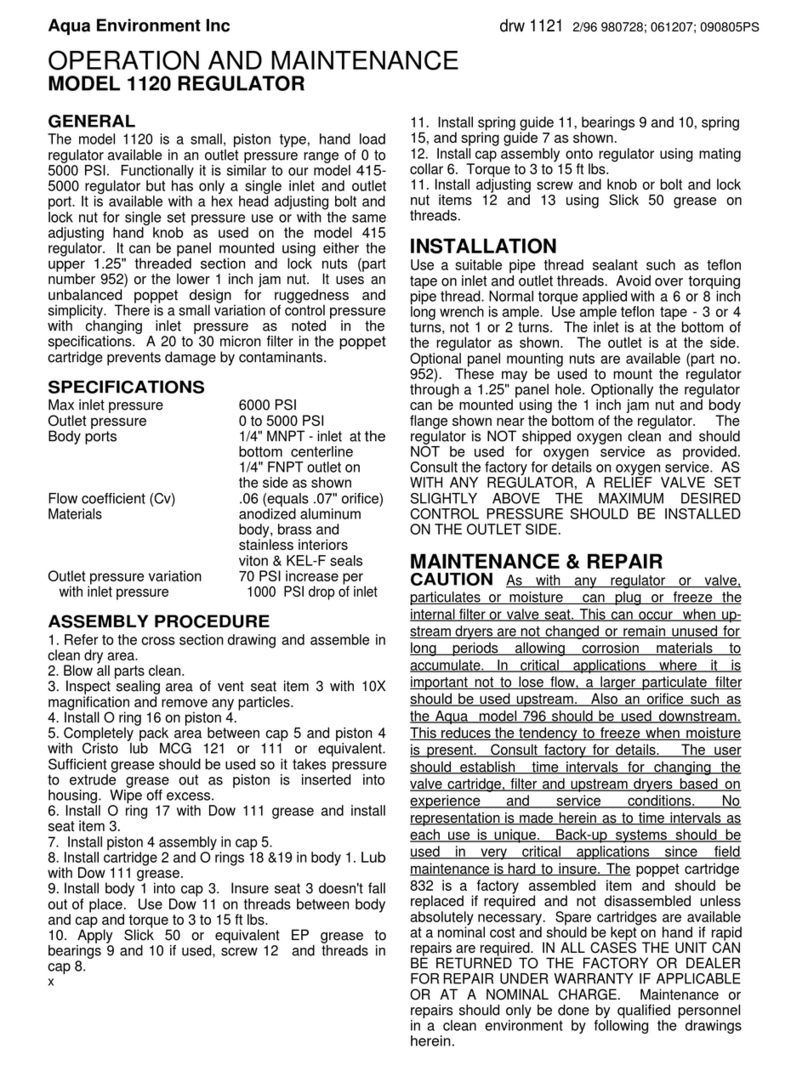

Outlet pressure is adjusted by knob 10 (refer to

drawing) to the desired value as read on the outlet

gauge. When reducing the pressure the regulator will

self vent via the vent hole near the

cap. This is normal.

When reducing set pressure reduce pressure

to below

the new setting

then increase pressure to the new

setting. If in-field adjustment is to be avoided, the

knob

10 can be replaced by a bolt and lock nut. A

3/8" by 24

thread per inch bolt with a minimum thread length if

one

inch is required.

MAINTENANCE & REPAIR

CAUTION

As with

any regulator or valve,

particulates or moisture

can plug or freeze the internal

filter or valve seat. This can occur

when up-stream

dryers are not changed or remain unused

for long

periods allowing

corrosion materials to accumulate. In

critical applications where it is important not to lose

flow,

a larger particulate filter should be used upstream.

Also

an orifice such as the Aqua model 796 should

be used

downstream. This

reduces the tendency to freeze

when moisture is present. Consult factory for details.

The user should establish time intervals

for changing

the valve cartridge, filter and upstream

dryers based on

experience and service

conditions. No representation

is made herein as to time intervals as

each use is

unique. Back-up systems should be used in very

critical

applications since field maintenance is hard to

insure.

The poppet cartridge 895 is a factory

assembled item and should be replaced if

required and

not disassembled unless absolutely necessary. Spare

cartridges are available at a nominal

cost and should be

kept

on hand if rapid repairs are required. IN ALL

CASES THE UNIT CAN BE RETURNED

TO THE

FACTORY IF APPLICABLE OR DEALER FOR

REPAIR

UNDER WARRANTY

OR AT A NOMINAL CHARGE.

Maintenance or repairs should only be

done by

qualified personnel in a clean environment by following

the drawings and parts lists herein.

If leakage occurs through the regulator or out

the

regulator vent, allow the inlet and outlet pressure to

equalize by shutting off the inlet. If leakage continues

after the inlet and outlet equalize the vent seat 5 or

piston seal 14 are leaking. Replace these.

If leakage

stops when the inlet and outlet pressure equalize

the

poppet cartridge item 1 is leaking. Replace this.

Aqua Environment Inc.

3100 Kerner Blvd, Ste N, San Rafael, CA 94901, (415) 453 8157