Cycle the pump slowly for at least 5 minutes, then

stop and disconnect the air hose. Push up on the

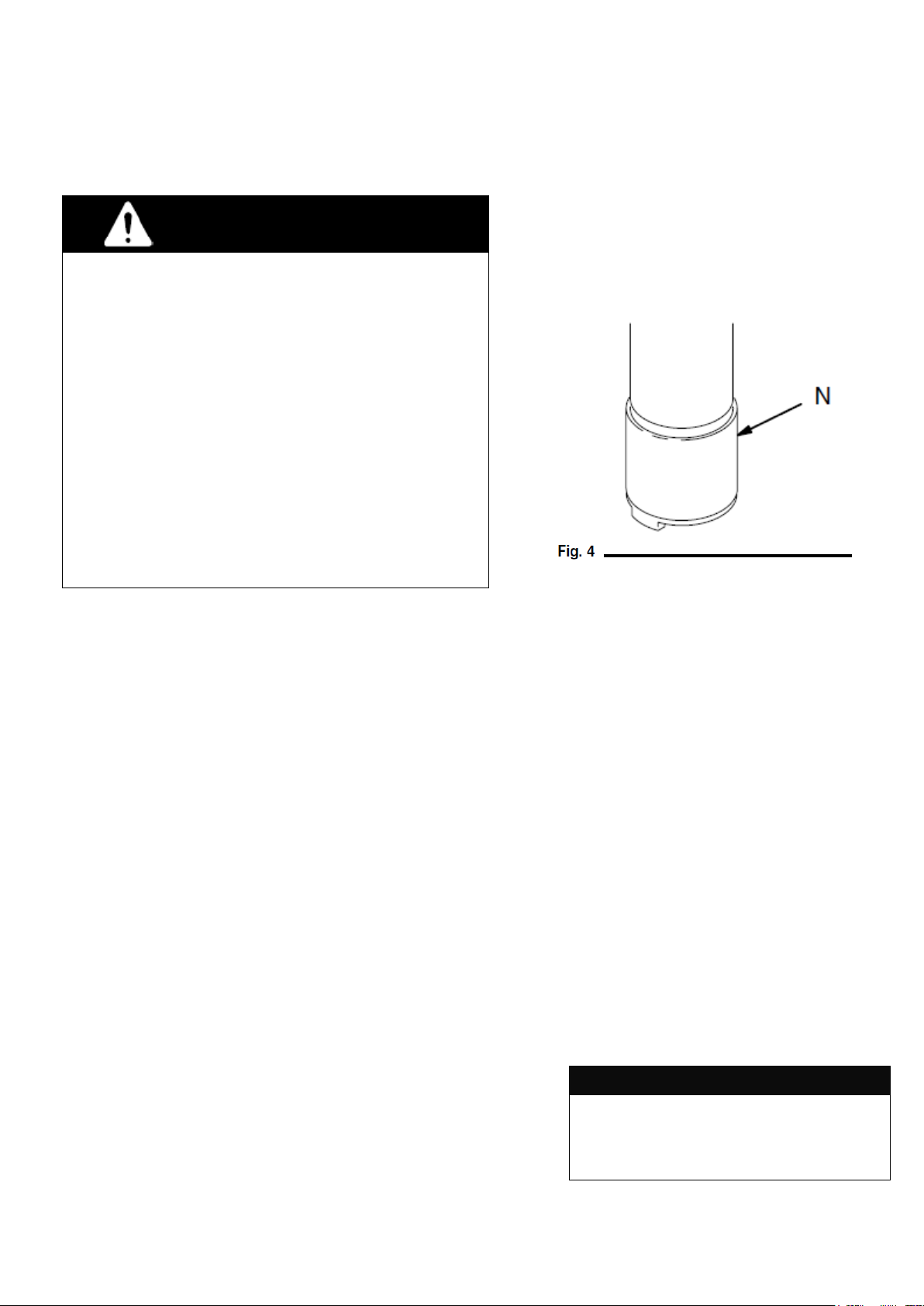

ball of the intake valve (N) to drain the lower part

of the pump. See Fig. 4. Turn the pump over to

drain the upper part of the pump.

Starting and Adjusting the Pump

With the air valve (K) or regulator (CC) closed, turn on

the air supply and connect the air line coupler (L). See

Figs. 3 or 5. Make sure all dispensing valves are open.

Slowly open the air valve (K) or regulator (CC) until the

pump cycles 5 to 20 cycles per minute. The pump itself

only takes a few strokes to prime. In a large system,

however, the pump may have to be cycled for several

minutes to fill all the lines. Once the entire system is

primed, use the air valve or regulator to control pump

speed and cycle rate; always use the lowest pressure

necessary to get the desired results. When used for

transfer and supply operations with no dispensing

valve, the pump will run whenever air is supplied.

Pump Shutdown

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the

Pressure Relief Procedure at left.

1. Disconnect the air line coupler (L).

2. Relieve the pressure.

Operation

Pressure Relief Procedure

1. Shut off the air to the pump.

2. Close the bleed-type master air valve (required in your system).

3. Hold a metal part of the dispensing valve firmly to the side of a

grounded metal pail, and trigger the valve to relieve pressure.

4. Open the fluid drain valve (required in your system) to relieve all

fluid pressure, having a container ready to catch the drainage.

5. Leave the drain valve open until you are ready to dispense

again.

If you suspect that the nozzle or hose is completely clogged, or that

pressure has not been fully relieved after following the steps above,

very slowly loosen the hose end coupling and relieve pressure

gradually, then loosen completely. Now clear the nozzle or hose.

Flush the Pump Before Using

The pump was tested in lightweight oil, which was left in to protect

pump parts. To prevent contamination of the fluid you are pumping,

flush the pump with a compatible solvent before using it. To flush

the pump, connect a short hose to the pump outlet, insert the pump

intake into a pail of compatible solvent, direct the hose into a pail,

PRESSURIZED EQUIPMENT HAZARD

The system pressure must be manually relieved to prevent

the system from starting or spraying accidentally. To reduce

the risk of an injury from accidental spray from the gun,

splashing fluid, or moving parts, follow the Pressure Relief

Procedure whenever you:

⚫are instructed to relieve the pressure,

⚫stop spraying,

⚫check or service any of the system equipment,

⚫or install/clean the spray nozzle.