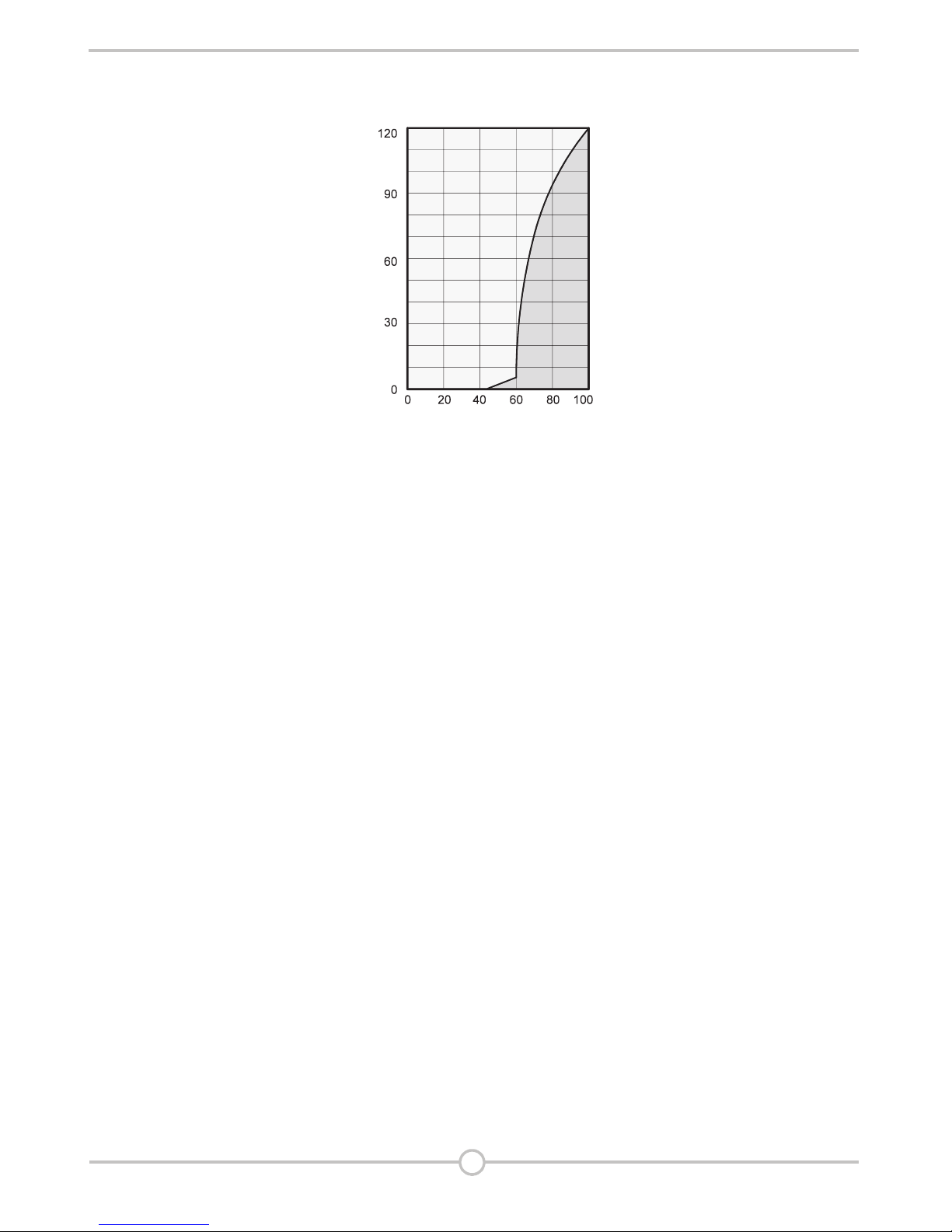

Itisevidentthatthecorrosion

ratebelow50% relative humidity

(RH) islow, and below 40%

isnegligible.

Thecorrosion rate increases

significantlyabove60% RH. This

threshold for damage as theresult

ofhumidityalsoappliestoother

materials, suchaspowdery

substances, packaging, wood

andelectronic units.

Buildingsmaybedriedinavariety

of

1. By heating and air exchange:

Theairintheroom is

heatedinorder for moisture

toberemoved and drained

outside. Alloftheenergy that

isinvolvedislosttogetherwith

themoistairthatisreleased.

2. By air dehumidification:

Themoistairthatispresent

withinanenclosedspace

iscontinuouslydehumidified

according to the condensation

principle.

Thecorrelations occurring when

airisdehumidifiedare based

onphysicallaws.

Theseare depicted here

ingraphicalforminorder

toprovide you with a brief

overviewoftheprinciplesofair

dehumidification.

Theuseof

AQUAairdehumidifiers

EvenifWindows and doors

are well insulated, water

andmoisture are capable

ofpenetratingeventhick

concrete walls.

Thewaterrequired

forsettingintheproduction

ofconcrete, mortar and plaster

etc. mayonlybediffused after

1-2months.

Evenmoisture trapped

inthemasonryafterhigh-

waterorafoodisreleased very

slowly.

Thesame is also true ofmoisture

containedinforexamplestored

materials.

Themoisture (water vapour)

released from parts of abuilding

ormaterialsisabsorbed

bythesurrounding air. As a result,

themoisture content increases,

whichultimatelygivesrise

tocorrosion, mould, rot, peeling

ofpaintandotherunwanteddamage.

Bywayofexample, thediagram

showsthecorrosion rate of metal

indifferent levels of humidity.

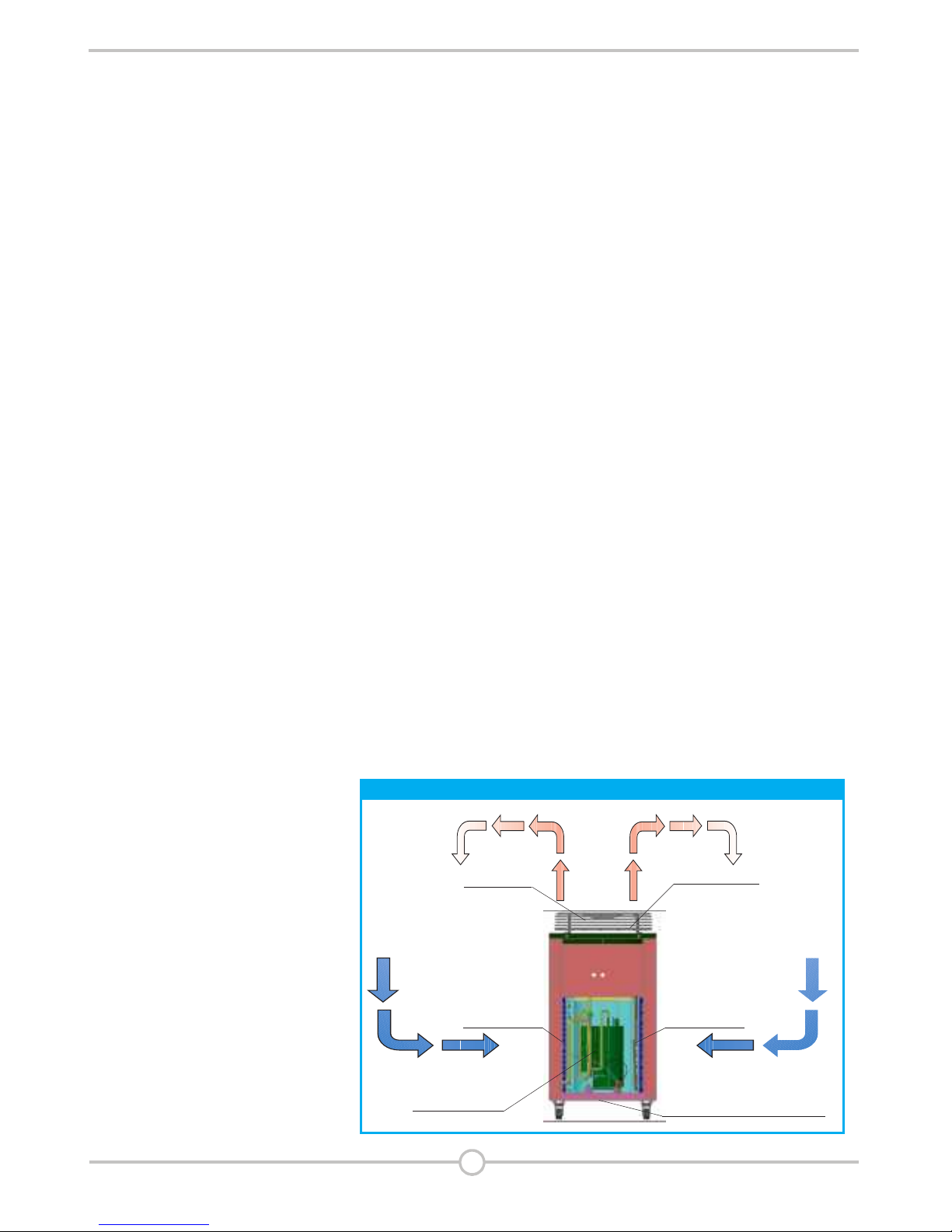

Air dehumidification

With regard to energy

consumption, airdehumidification

hasonedistinctadvantage:

Energy expenditure is limited

exclusivelytotheairvolumes

present., The mechanical heat that

isreleased by the dehumidification

process is fed back into the room.

Under normal use, the air

dehumidifier uses approximately

25% of the energy that

is required for the "heating

and ventilating" principle.

Relativehumidity

Ourambientairisagaseous

mixture which always contains

acertainvolumeofwater

intheformofwatervapour.

Thisvolumeofwaterisspecified

ingperkgofdryair(absolute

moisture content).

1m3ofairweighsapprox.1.2kg

at20°C

Dependingonthetemperature,

eachkgofairisonlycapable

ofabsorbingacertainvolume

ofwatervapour. Once this

capacityhasbeenreached, the

airisreferred to as "saturated"

andhasarelative humidity (RH)

of100%.

Relativehumidityisunderstood

tomeantheratiobetween

thecurrent volume of water

vapourin the air and the maximum

possiblevolumeofwatervapour

atthesametemperature.

Theabilityoftheairtoabsorb

watervapourincreases

asthetemperature rises.

I.e. themaximumpossible

(absolute) watercontentbecomes

greater as the temperature rises.

4

Air dehumidifIers

■

■

■

■

corrosion rate

Relative humidity%