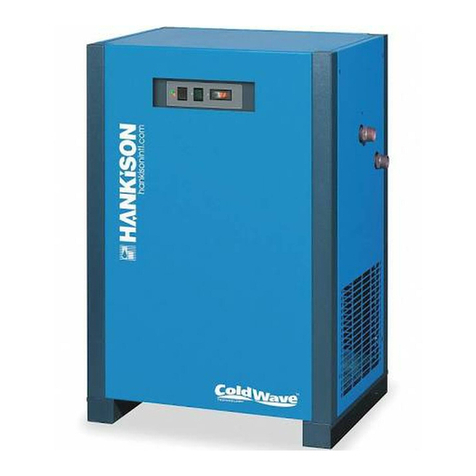

SPX Hankison HPRplus Series User manual

REFRIGERATED

TYPE

COMPRESSED

AIR DRYERS

CONTENTS

GENERAL SAFETY INFORMATION.......................2

RECEIVING, MOVING, AND UNPACKING.............2

1.0 INSTALLATION .................................................3

2.0 OPERATION .....................................................5

3.0 MAINTENANCE................................................10

SIZING.....................................................................11

ELECTRICAL SCHEMATICS

Models 1000 and 1250.........................................12,13

Model 1500 ..........................................................14,15

Models 1750, 2000 and 2500...............................16,17

Model 3000 ..........................................................18,19

DIMENSIONS / WEIGHTS......................................20

ENGINEERING DATA .............................................21,22

TROUBLESHOOTING GUIDE................................23

PARTS LIST ............................................................24

WARRANTY ............................................................28

SERVICE DEPARTMENT: (724) 746-1100

INSTRUCTION MANUAL

HPRplus Series with ColdWave™ Technology

Models: HPRP 1000, 1250, 1500, 1750,

2000, 2500, 3000

5001321 Rev. B 8/08

2

RECEIVING, MOVING, AND UNPACKING

A. RECEIVING

This shipment has been thoroughly checked, packed and

inspected before leaving our plant. It was received in good

condition by the carrier and was so acknowledged.

Check for Visible Loss or Damage. If this shipment shows

evidence of loss or damage at time of delivery to you,

insist that a notation of this loss or damage be made on

the delivery receipt by the carrier’s agent.

B. UNPACKING

Check for Concealed Loss or Damage. When a shipment

has been delivered to you in apparent good order, but

concealed damage is found upon unpacking, notify the

carrier immediately and insist on his agent inspecting

the shipment. Concealed damage claims are not our

responsibility as our terms are F.O.B. point of shipment.

C. MOVING

In moving or transporting dryer, do not tip dryer onto its

side.

D. STORAGE/SHUT DOWN

Dryer should not be stored outside (either

packed or unpacked) or exposed to the weather. Damage to

electrical and control components may result.

IMPORTANT: WATER-COOLED UNITS - If unit is shut down

below freezing temperatures, the water-cooled condenser may

freeze and cause permanent damage. Condenser must be

drained when the unit is shut down.

IMPORTANT: Do not store dryer in temperatures above 130°F

(54°C).

GENERAL SAFETY INFORMATION

1. PRESSURIZED DEVICES:

This equipment is a pressure containing

device.

• Donotexceedmaximumoperating

pressure as shown on equipment

serial number tag.

• Makesureequipmentisdepressurizedbeforeworking

on or disassembling it for service.

2. ELECTRICAL:

This equipment requires electricity to

operate.

• Installequipmentincompliancewith

all applicable electrical codes.

• Standardequipmentissuppliedwithelectrical

enclosures not intended for installation in hazardous

environments.

• Disconnectpowersupplytoequipmentwhenperforming

any electrical service work.

3. BREATHING AIR:

• Airtreatedbythisequipmentmay

not be suitable for breathing without

furtherpurication.

Refer to applicable standards and

specicationsfortherequirements

for breathing quality air.

3

IMPORTANT: READ PRIOR TO STARTING THIS EQUIPMENT

1.0 INSTALLATION

1.1 Location

A. For typical placement in a compressed air system, see

drawing.

B. Air compressor intake – Locate air compressor so that

contaminants potentially harmful to the dryer (e.g.

ammonia) are not drawn into the air system.

C. Dryer should be installed in a moderately heated, well

ventilated area. Avoid locations immediately adjacent

to cold exterior windows or walls, or adjacent to high

temperature ovens or boilers.

D. Clearances:Freeairow

Front 37.3/8 inches (950 mm)

Back 37.3/8 inches (950 mm)

Left Side 37.3/8 inches (950 mm)

Right Side 6 inches (153 mm)

Top 25.5/8 inches (650 mm)

Service - To facilitate maintenance leave 37.3/8 inches

(950 mm) of clearance in front of dryer.

E. Standard units are designed to operate in ambients:

Air-cooled: 40 to 110°F (4 to 43°C).

Water-cooled: 40 to 130°F (4 to 54°C).

F. Dryer is designed to operate at all altitudes - no

adjustment for altitude is required.

G. Theinstallationofaexibleconnectionpriortothedryeris

recommended to prevent possible damage from vibration.

NOTE: Outdoor installation – Standard units are designed for

indoor installation. Contact manufacturer if installing outdoors.

Aftercooler

Separator

Dryer

Compressor

COOLING WATER

INLET

COOLING WATER

OUTLET

COOLING WATER

OUTLET

COOLING WATER

INLET

FILTER MONITOR

(OPTIONAL)

COOLING AIR FLOW

COOLING AIR FLOW

CONDENSATE DRAIN

(OPTIONAL)

CONDENSATE DRAIN

CONDENSATE DRAIN

LEFT SIDE VIEW

CONTROL PA NEL

FRONT SIDE VIEW

SEE DETAILS ‘A’ AND ‘B’

FOR WATER CONNECTION

PORT IDENTIFICATION

DETAIL ‘A’

Cooling Water Connection Ports for

Models 1000, 1250, 1500

DETAIL ‘B’

Cooling Water Connection Ports for

Models 1750, 2000, 2500, 3000

4

1.2 Mounting

Mount the dryer on a level solid surface. Holes are provided in

thedryerbasetopermanentlymountthedryertotheoor.

1.3 Piping Connections

A. Air Inlet - Connect compressed air line from air source to

air inlet.

Refer to Serial Number Tag for maximum

working pressure. Do not exceed dryer’s Maximum Working

Pressure.

NOTE: Install dryer in air system at highest pressure possible

(e.g. before pressure reducing valves).

NOTE: Install dryer at coolest compressed air temperature

possible. Maximum inlet compressed air temperature: 120°F

(49°C). If inlet air exceeds this temperature, precool the air with

an aftercooler.

B. Air Outlet - Connect air outlet to downstream air lines.

C. Bypass piping - If servicing the dryer without interrupting

the air supply is desired, piping should include inlet and

outlet valves and an air bypass valve.

D. Water-cooled models - cooling water inlet and outlet

1. Connect cooling water supply to cooling water inlet.

2. Connect cooling water return line to cooling water

outlet connection.

NOTE: Strainer and water regulating valve are supplied on

water-cooled models. Also, it is recommended to add water

inlet/outlet temperature and pressure gauges to the water

piping.

1.4 Electrical Connections

IMPORTANT: Use copper supply wires only.

A. Dryer is designed to operate on the

voltage, phase, and frequency listed on

the serial number tag.

B. Electrical entry is through a hole in the

top of the cabinet. Route wires through the bottom of the

electrical enclosure. Connect power source to the terminal

strip in the electrical enclosure as shown on the electrical

schematic included with the dryer.

NOTE: Refrigeration condensing unit is designed to run

continuously and should NOT be wired to cycle on/off with the

air compressor.

1.5 Electronic Demand Drain

A. An automatic electric demand drain (EDD)

discharges condensate removed by the

separator.

B. All dryer models are supplied with one

EDD. Models with the additional (optional)

oilremovallteraresuppliedwithasecond

EDD.

C. Thedrainsarepipedtottingsinthelegoftheunit.

Condensateshouldbepipedfromthisttingtoanopen

ventedoordrainorsump.

NOTE:Discharge is at system pressure. Drain line should be

anchored.

NOTE:Condensate may contain oil. Comply with applicable

laws concerning proper disposal.

D. Verify that isolation valves are open. If the drain fails to

discharge after the valve is energized, the electronic con-

trol circuit will repeatedly energize the valve in an attempt

to clear the discharge port. If, after 60 seconds, the drain

still fails to discharge, the control circuit then switches to

the alarm mode. In this mode the valve is de-energized

and the red alarm light is activated on the drain and the

dryer controller. The valve is then automatically energized

every 4 minutes for 5 seconds. Check the drain operation.

Push drain (push-to-test) button on the Energy Manage-

mentMonitorcontrolboardtoenergizedrain.Aowof

condensate and/or air should be present at the drain

outlet. The alarm mode automatically clears after the drain

returns to normal operation.

E. Description of Operation: Condensate enters the

reservoir (1) through the inlet port. When the conden-

sate level in the reservoir covers the capacitance sensor,

an electronic signal is sent to the solid state countdown

processor. The processor delays the opening of the sole-

noid valve for a given period of time. Once the time has

elapsed, the solid state processor transmits information to

energize the coil in the solenoid valve (2). The magnetic

force of the coil causes the solenoid core (3) to move,

closing the pilot air supply line and opening the pilot air

exhaust line. After the pilot air above the diaphragm (4) is

vented, pressure in the reservoir opens the discharge port

and forces the condensate through the discharge port and

outlet piping.

1

2

3

4

5

2.0 OPERATION

2.1 Minimum/Maximum Operating Conditions

A. Maximum inlet air pressure: refer to dryer serial number

tag

B. Minimum inlet air pressure: 30 psig (2.1 barg)

C. Maximum inlet air temperature: 120°F (49°C)

D. Maximum ambient temperature:

Air-cooled models: 110°F (43°C)

Water-cooled models: 130°F (54°C)

E. Minimum ambient temperature: 40°F (4°C)

2.2 Start-up

A. Energize dryer. Green power on light will illuminate.

IMPORTANT: Energize dryer for 24 hours before refrig-

eration compressor is started! Never use the disconnect

switch to shutdown the dryer for an extended period of

time (except for repair). Failure to follow these instructions

may result in a non-warrantable compressor failure.

B. Program Monitor

Press and hold Program Mode button until Main Menu screen

appears. Use the Up and Down arrow buttons to scroll through

the list of sub-menu choices. Press Enter button to view the

sub-menu that is displayed. Press ESC to exit the Main Menu

and return to Display mode.

1. Language Selection

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll through

the list of languages (choice of 10 available: English,

Deutsch, Francais, Espanol, Italiano, Polski, Dansk,

Dutch, Norsk and Suomi).

b. Press ‘Enter’ button to select the language that is

displayed.

c. Push ‘ESC’ at any time to return to the Main Menu.

2. Setting Date & Time

a. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes

(00 to 59). Press ‘Enter’ to accept new value.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set hours (00

to 23). Press ‘Enter’ to accept new value.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set year (00

to 99 representing 2000 to 2099). Press ‘Enter’ to

accept new value.

d. Use the ‘Up’ and ‘Down’ arrow buttons to set month

(three letter abbreviation). Press ‘Enter’ to accept new

value.

e. Use the ‘Up’ and ‘Down’ arrow buttons to set day (01

to maximum for the month and year selected). Press

‘Enter’ to accept new value.

f. Push ‘ESC’ at any time to return to the Main Menu.

1. Temperature Indicator

2. Operator Interface Display

3. Power-on Light

4. Compressor-on Light

5. Alarm / Service Light

6. Schedule On/Off and Enter Button

a. In display mode: Press to toggle between

SCHEDULE RUNNING and MANUAL OVERRIDE.

b. In program mode:

i. Press to move to a lower level menu.

ii. Press to accept a value that has been edited.

7. Program Mode (i) and Esc

a. In display mode: Press and hold to enter program

mode.

b. In program mode: Press to move to a higher level

menu.

8. Up Arrow

a. In display mode: No function

b. In program mode:

i. Press to view the next item in a list or to

increment a variable to a higher value. Press

and hold for accelerated incrementing.

ii. When the top of the list (or highest value) is

displayed, pressing the up button will cause

the display to wrap to the bottom of the list (or

lowest value).

9. Down Arrow

a. In display mode: No function

b. In program mode:

i. Press to view the previous item in a list or to

increment a variable to a lower value. Press

and hold for accelerated incrementing.

ii. When the bottom of the list (or lowest value) is

displayed, pressing the down button will cause

the display to wrap to the top of the list (or

highest value).

10. 1/0: Press at any time to turn the dryer on/off.

11. Drain test: Press at any time to momentarily open the

drains.

12. Reset: Press at any time to clear the alarm/service

message (if shown) and the alarm LED.

CONTROL PANEL

1234 5

678

9 10 11 12

6

3. Setting Schedule

a. Use the ‘Up’ and ‘Down’ arrow buttons to select desired

“Day of week + on/off”. Press ‘Enter’ to accept new

value

b. Use the ‘Up’ and ‘Down’ arrow buttons to set hour (00

to 23). Press ‘Enter’ to accept new value

Note: If the hour setting is ‘IGNORE’, Press ‘Enter’

again to move the cursor under the “Day of week +

on/off”.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes

(00, 10, 20, 30, 40, 50; not shown if hour setting is

‘IGNORE’). Press ‘Enter’ to accept new value and

return to “Day of week + on/off”. Repeat steps a

through c as needed.

d. Push ‘ESC’ at any time to return to the Main Menu.

4. Hours To Service

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll through

the range of permissible values (0 to 8760) before

service reminder is initiated. Press ‘Enter’ to accept

new value. (Only hours that refrigeration compressor is

operating are counted).

b. Press ‘ESC’ at any time to return to the Main Menu.

NOTE: On dryers with air-cooled condensers, regular

condenser cleaning is recommended. Dirtiness of

ambient air at installation site will determine frequency

of service. Typically once a month is recommended.

NOTE:Alldryerscontainanintegral3micronlter.

Asthelterelementaccumulatessolidcontaminants,

differential pressure increases. Solid particulate load in

the compressed air supply will determine frequency of

service. Typically element changeout is recommended

at least annually.

5. Alarm History

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll through

the last twenty (20) alarms beginning with the most

recent alarm.

NOTE: The number at the end of the top line with a

cursorunderneathidentieswhichofthepasttwenty

alarms is being displayed.

b. Press ‘ESC’ at any time to return to the Main Menu.

c. To clear the alarm history, press and hold the ‘Enter’

button then press the ‘Up’ arrow button. Release both

buttons.

6. Push ESC button to exit program mode.

NOTE: If after 60 seconds no button is pressed while

inProgramMode,theaudiblealarmsoundsforve(5)

seconds and the controller exits program mode. Dryer will

resume previous operating mode.

C. Starting Dryer

IMPORTANT: Dryer must be energized 24 hours before starting

refrigeration compressor.

NOTE: It is recommended that dryer be started 15 minutes

beforecompressedairowbegins.

1. On water-cooled models: after 24 hours and before

startingdryer,begincoolingwaterow.

2. Check for proper electrical voltage.

3. Slowly pressurize unit air side by opening inlet isolation

valve. Check for leaks.

4. After 15 minutes, open outlet isolation valve slowly.

5. Close air bypass valve.

6. Dryer may be operated in Manual or scheduled modes.

NOTE: Check for correct phasing of unit. On air-cooled

models: check fan rotation (air must be pulled through the

condenser). Fans may not start immediately or may cycle on

and off. If rotation is in the wrong direction follow the procedure

below. On water-cooled models: After starting dryer if an

unusual noise is heard and the discharge line does not get

hot, stop the dryer, reverse two power leads, restart, and verify

discharge line gets hot.

a. Manual mode - push ‘On/Off’ button - refrigeration

compressor will start and run, green Compressor-on

light will illuminate. In this mode compressor will run

continuously and will not be turned on and off by the

monitor. MANUAL OVERRIDE will appear on interface

panel.

b. Schedule mode - push ‘Schedule On/Off and Enter’

button. SCHEDULE RUNNING will appear on the

interface panel. The refrigeration compressor will

continue to be on or off (as selected in the Manual

Override Mode) until the next scheduled event. The

compressor will then turn on or off as programmed.

NOTE: Dryer may be returned to the manual mode at any

time using the ‘Schedule On/Off and Enter’ button. MANUAL

OVERRIDE will appear on interface panel. To reinstitute

Schedule, push the ‘Schedule On/Off and Enter’ button again.

NOTE: Restart after the power interruption. Unit will be in

MANUAL OVERRIDE mode, refrigeration compressor, off

when power is restored after power interruption.

7. To reinstitute SCHEDULE RUNNING: push ‘Schedule On/

Off and Enter’ button.

IMPORTANT: Dryer must be energized 24 hours before

refrigeration compressor is started.

D. Operating Check Points

1. Check that green Power-on light is illuminated.

2. Check that green Compressor-on light is illuminated if

dryer is on in the manual mode or it is a scheduled on

time.

IMPORTANT: Refrigeration compressor must be restarted

after power interruption.

3. Check Interface Panel.

NOTE: Interface panel will scroll through three screens

(Current Time/Operating Status, Hours to Service, and Total

Operating Hours).

a. Verify that current time is correct.

b. Check HRS TO SERVICE: this indicates time

remaining until service is required; allow time for

required maintenance items to be ordered.

c. Check operating status:

MANUAL OVERRIDE - Dryer is either running

continuously (not being controlled by the scheduled

on/off times) or the refrigeration compressor has been

shut off using the ‘On/Off’ button.

7

SCHEDULE RUNNING - Refrigeration compressor

is being turned on and off by the monitor per-

programmed schedule (see B.3. to set schedule).

d. Check Temperature indicator - indicator should read in

the green area.

e. Check Alarm/Service light. If illuminated, check Interface

panel.

1) If SERVICE DRYER appears, scheduled

maintenance time has elapsed (HRS TO

SERVICE is 0). Perform needed service and reset

service interval (see B.4.).

2) If ALARM appears, a dryer fault is indicated; see

Troubleshooting Guide for possible remedies.

After fault correction push Reset button to turn

Fault alarm off.

Type of FAULTS:

LOW PRESSURE - the refrigeration compressor

control circuit has opened because of low suction

pressure.

HIGH PRESSURE - the refrigeration compressor

control circuit has opened because of high head

pressure. The high pressure switch must be reset

manually once the fault is corrected. Red reset

button is located on pressure switch inside unit.

HIGH EVAPORATOR TEMPERATURE - com-

pressed air temperature is above the set point.

COMPRESSOR - normally open (NO) auxiliary

contact on the compressor contactor is open when

the dryer is on.

HEATER - normally closed (NC) auxiliary contact

on the compressor contactor is open when the

dryer is off.

TEMP SENSOR - occurs if the temperature sensor

circuit is open or shorted. If open, the left-most

LED in the temperature display will be illuminated.

If shorted, all the LEDs in the temperature display

will be illuminated.

DRAIN - electric drain contains a high water level

alarm that activates if drain fails to discharge.

f. Check drain operation - push Drain (push-to-test)

buttontoenergizeelectricdrain.Aowofcondensate

and/or air should be present at the drain outlet.

E. Using the RS-232 Port

The RS-232 port is used to monitor dryer operation from

a host computer. A (1 to 1) DB-9 cable is required to

connect dryer and computer. For PC connections, data

is transmitted on pin 2, received on pin 3, ground is pin 5,

pins 7 and 8 are jumpered at dryer.

Operationisatxedbaudrateof9,600;asynchronous

format is 8 bit, no parity, 1 stop bit (“8,N,1”). No check

sum or error correction values are provided. If required,

request status string two (or more) times and compare for

agreement.

Request data by sending ASCII ? character (3FH). Re-

sponse may take up to two seconds as certain process-

ing functions may require completion before serial port is

acknowledged.

Dryer responds with line feed (0AH), carriage return (0DH),

and character string: (1), (2), (3), (4), (5), (6), (7), (8), (9)

(1) = STX (start-of-text character, may appear as a smiley

face or some other character

(2) = 108, Control board ID

(3) = 0 or 1, Compressor running status (0=off, 1=on)

(4) = M or S, Operating Mode (M= MANUAL OVERRIDE,

S = SCHEDULE RUNNING)

(5) = xxxx, HOURS TO SERVICE

(6) = xxxxxx, TOTAL HOURS

(7) = xx, Alarm or Service Code

0 = no alarm,

30 = LOW PRESSURE ALARM,

31 = HIGH PRESSURE ALARM,

32 = COMPRESSOR ALARM,

36 = HIGH EVAP TEMP ALARM,

37 = HEATER ALARM,

38 = DRAIN ALARM,

39 = SERVICE DRYER,

41 = TEMP SENSOR ALARM

(8) = xx.x, Evaporator temperature (°F)

(9) = ETX, (end-of-text character, may appear as a heart

or some other character)

8

2.3 Filter Monitor (optional)

The Filter Monitor continuously monitors the differential pres-

sure (pressure drop) across the standard grade 9 element in

the moisture separator. Models with the optional grade 5 Oil

Removal Filters include a dedicated Filter monitor as well to

alert the operator of the need for element replacement when

any of three operating criteria are met:

1. Maximum elapsed time (service interval) before change-

out - operator alerted when user selected time period

elapses.

2. Maximum allowable differential pressure - operator

alerted when user selected maximum differential

pressure occurs.

3. Intelligence - operator alerted when the optimum time

to replace the element(s) has occurred. The Monitor

calculates this using the element type, the initial

characteristic pressure drop and historical pressure drop

data.

Recommended Settings for Integral Filtration

1. Maximum time before element replacement:

2. Maximum pressure differential:

Programming Instructions

(Short version - for complete instructions see page 9)

1. To begin programming, press and hold ENTER button

for 3 seconds.

2. Press and hold the scroll button to input maximum

service interval (1 to 15 months) - press ENTER.

3. Press and hold the scroll button to select pressure unit

of measure (KG/CM2,PSI, or BAR). - press ENTER.

4. Press and hold the scroll button to input maximum

pressure drop (0.01 to 1.00 KG/CM2 or BAR; 0.1 to

15 PSI) Use Left Shift and Right Shift buttons to select

advance rate (e.g. by ones, tenths, or hundredths)

-press ENTER.

5. Press and hold the scroll button to select the element

letter type (see chart above) - press ENTER.

6. Select Initialize or Run mode.

Initialize - Scroll until initial pressure drop and run icons

are displayed. (To be selected during initial installation

and element charge out).

Run -Scroll until run icon only is displayed. (To be

selected if Monitor is reprogrammed without changing

the element).

7. Press ENTER to start program.

2.4 Display Legend

LED DISPLAY

1. Unit of measure selection - pressure - pounds per square

inch.

2. Unit of measure selection - pressure - kilograms per

square centimeter.

3. Unit of measure selection - pressure - bar.

4. Indicates that predicted number of days until element

replacement required is being displayed or with 13 to

indicate element replacement required because maximum

time has elapsed.

5. Displayed with 7 in program mode when inputting maxi-

mum time before element replacement.

6. Indicates Monitor is in program mode.

7. Displayed in program mode when inputting maximum time

before element replacement.

8. Displayed in program mode with 10 when inputting ele-

ment type.

9. Displayed alone when Run mode selected or with 14 and

15 when Initialize mode selected.

10. Displayed in program mode with 8 when inputting element

type.

11. Displayed in program mode when inputting maximum dif-

ferential pressure or with 13 to indicate element replace-

ment required because maximum pressure differential has

occurred.

12. Indicates Monitor is processing data. Or with 13 to indicate

element replacement required due to intelligence.

13. Indicates need for element replacement.

14. Indicates (displayed with 15) that initial characteristic pres-

sure drop is being displayed.

15. Indicates that current pressure drop is being displayed.

16. Indicates (displayed with 15) that average pressure drop is

being displayed.

17. Indicates need for battery replacement.

1

234

567

9

101112131415

16

17

8

INITIAL P ICON

SHIFT LEFT

BUTTON

SHIFT RIGHT

BUTTON

SCROLL

BUTTON

ENTER

BUTTON

OPERATOR

ALERT LIGHT

(RED LED)

LIQUID

CRYSTAL

DISPLAY

RUN ICON

Table 1

Standard Grade 9 Optional Grade 5

Model

Number

Moisture Separator

Pressure Drop Setting

Element

Setting

Oil Removal Filter

Pressure Drop Setting

Element

Setting

Service

Interval

psig kgf/cm

2

bar Letter

Type psig kgf/cm

2

bar Letter

Type

Grade

9 & 5

1000 1.00 0.07 0.07 B 5.5 0.39 0.38 E As

indicated

by

Filter

Monitor

Display, or

Annually

1250 1.50 0.11 0.10 B 6.5 0.46 0.45 E

1500 2.00 0.14 0.14 B 8 0.56 0.55 E

1750 1.00 0.07 0.07 B 4.5 0.32 0.31 E

2000 1.00 0.07 0.07 B 5.5 0.39 0.38 E

2500 1.50 0.11 0.10 B 6.5 0.46 0.45 E

3000 2.00 0.14 0.14 B 8 0.56 0.55 E

9

Initialize

Use Initialize on initial start-up or after

replacing elements. See section 2.3

for programming instructions.

If Initialize is selected the program

willignoretherst24hoursofoperationtoallowthe

element(s) to achieve a steady state. After this period,

pressure drop measurements will be averaged over the

next 144 hours to determine an initial characteristic pres-

sure drop. The differential pressure calculation used to

determine the optimum time for element replacement uses

this characteristic drop as the starting point.

After the initialization period, Monitor automatically

switches to the Run mode.

Run

To select Run, press Scroll button so that only

the run icon is displayed. If RUN is selected,

the monitor uses the previous initial charac-

teristic pressure drop as the reference. Use

this mode if the Monitor is re-programmed but the element

is not replaced.

12. Press Enter button to exit program mode and begin opera-

tion.

2.7 Display

1. Run mode - in the run mode, Processing

iconashes;indicatingthattheMonitoris

processing data.

2. Readouts - the display cycles through the following read-

outs:

a. Current differential pressure.

b. Average differential pressure over the past

24 hours.

c. Projected days until element replacement.

WhentheMonitorestimatesthatlterelementreplace-

ment will occur within 60 days, the days remaining will

be displayed. This allows time to have replacement

element(s) on hand.

2.8 Alarms

a. Indication of need for element replacement.

If any criteria for element replacement is met, the red

LEDwillash.

1) Need for replacement based

on expiration of maximum

time - “0 days” displayed

2) Need for replacement based

on maximum pressure drop -

inputted maximum pressure

drop displayed.

3) Need for element replace-

ment based on intelligence

(calculated optimum time).

b. Need for battery replacement - Battery

IconandredLEDwillash.

2.5 Filter Monitor Power Supply

Each Filter Monitor receives transformed DC power from the

control circuit through an RJ11 connection pin.

A. Element Status Retention Batteries

Three batteries are pre-installed inside each Filter Monitor

to retain element condition characteristics during power

outages.

Replacement - Remove battery compartment cover and the

three old batteries. Consult the compartment cover for proper

orientation then, install three fresh AA, 1.5 V batteries. Re-

install cover.

Life - Batteries perform a back-up function. A 15-24 month life

cycle is anticipated. Replace batteries prior to their expiration

duringaplannedlterelementchangetoretaintheelement

signatureandensurethemaximumlterelementlifecycle.

Memory - Pre-programmed settings are retained during battery

expiration and replacement. To keep the existing settings, the

Filter Monitor will require initialization as described in section

3.3B. To change the programming, see section 2.3.

2.6 Programming

1. Afterbatteriesareinstalled,redLEDlightwillglowbriey;

displaywillashuntilunitisprogrammed.

2. Press and hold Enter button for 3 seconds to begin pro-

gramming.

3. Select maximum elapsed time before element replace-

ment - press Scroll button to advance from 1 to 15 months.

4. Press Enter button to accept choice.

5. Select unit of measure for pressure - use Scroll button to

choose between KG/CM2, PSI, or BAR

6. Press Enter button to accept choice.

7. Select maximum allowable pressure drop - use Scroll but-

ton to advance from 0.01 to 1.00 KG/CM2 or BAR; or 0.1

to 15 PSI. Use Shift buttons to change advance rate (BAR

and KG/CM2 -tenths or hundredths; PSI - tenths or ones).

8. Press Enter button to accept choice.

9. Input element type - use Scroll button to advance from “A”

to “H”. See chart on Page 1 for reference.

10. Press Enter button to accept choice.

11.

Select Initialize or Run modes.

10

3.0 MAINTENANCE

3.1 Monthly

A. Air-Cooled:Cleanrefrigerantcondenser.Blowthens

of the condenser clean with compressed air, if necessary,

remove heavier soiling with a suitable cleansing agent.

B. Water-cooled - clean strainer monthly, more often if

required. Shut off water, remove small plug to relieve pres-

sure, then remove large plug to remove strainer. Clean

strainer and replace.

C. Check the condensate drains by pressing the Drain Test

button on the control panel (see page 5 for description and

location). Visually check to assess whether condensate is

separated and discharged.

D. Check the dew point temperature on the control panel.

E. Check the inlet compressed air temperature and the ambi-

ent temperature (or inlet cooling water temperature) to

assure they are within the operational limits.

Ref: 3.2, C, 2, e through h

3.2 Annual Maintenance

A. Check all terminals in the switchgear cabinet and tighten

them up if necessary.

Check to be sure the unit is de-energized.

B. Maintenance/Cleaning of the condensate drain.

3 2

1

4

Check to be sure the unit is depressurized

and de-energized.

Maintenance recommendation:

1. Remove two pan head screws [1] and lift off conden-

sate drain. The elbow adapter stays in place.

2. Disconnect discharge hose [2].

3. Turn the 6 pan head screws [3] until heads are level

with the outer edge and take off diaphragm seat [4].

4. Replace wearing parts. (All necessary service parts

can be ordered in a service kit – See Parts List.)

5. Reassemble condensate drain unit in reverse order.

C. Replacetheltercartridgesinthelter.(Allnecessary

service parts can be ordered in a service kit – See Parts

List.)

1. When to replace the Separator/Filters.

Replacelterelementwhenpressuredropacross

dryer is excessive or annually.

1

2 3 4

11

SIZING

Determining dryer capacity at actual operating conditions.

Todeterminethemaximuminletowcapacityofadryeratvari-

ous operating conditions, multiply the rated capacity from Table

1 by the multipliers shown in Table 2.

Example: How many scfm can a 60 Hz air-cooled model 1000

handle when compressed air to be dried is at 200 psig and

100°F; ambient air temperature is 80°F?

Answer: 1,000 x 1.22 x 1.12 = 1,366 scfm.

TABLE 1

Rated capacity (scfm) @ 100 psig inlet pressure, 100°F inlet

temperature, and 100°F ambient temperature.

MODEL 1000 1250 1500 1750 2000 2500 3000

Rated capacity

of air-cooled

models (scfm)

60 Hz

50 Hz

1000

830

1250

1050

1500

1250

1750

1460

2000

1670

2500

2080

3000

2500

Whenremovingliquidsatratedowconditions,the

pressure drop will be 5 psi (0.35 bar), or less, across

the entire dryer. An increase in pressure drop will

occuronlyastheseparator/lterelementsbecome

loaded with solid particles. It is recommended, for

maximumltrationefciency,theseparator/lterele-

ments be replaced when the pressure drop across the

dryer exceeds 10 psi (0.7 bar), or every 12 months,

whicheveroccursrst.

2. Replacement of the Separator/Filters

Depressurize the unit before servicing.

Failure to do this may result in injury.

a. Open the bypass between compressed air inlet and

outlet. (if equipped)

b. Close the shut-off devices at the compressed air

inlet and outlet.

c. Press the Drain Test button on the control panel

(see page 5 for description and location) until the

system is depressurized.

d. Switch off the dryer.

e. Remove the insulation [1].

f. Loosenthescrews[2]ofthelterhousing.Caution

is necessary as the system may still be under slight

residual pressure.

g. Removeallscrewsexceptoneandswingange[3]

to the side.

h. Pull out the old cartridges [4].

i. Push new cartridges on to the mounting posts in the

bottom of the separator vessel.

NOTE: Do not touch the foam sleeves of the

cartridgeswithyourngers.

j. Close housing in reverse order.

k. Put on insulation.

l. Switch on the dryer.

m. Repressurize the dryer by slowly opening the

compressed air inlet valve.

n. Slowly open the compressed air outlet valve.

o. Slowly close the compressed air bypass valve (if

equipped).

3.3 Filter Monitor Programming (optional)

A. Each Filter Monitor needs to be initialized whenever a new

lterelementisinstalled.InitializationresetstheIntel-

ligence circuitry to begin establishing a new performance

baseline consistent with the unique signature of each

individual element.

B. To retain the existing settings previously established

simply:

1. Press and hold the “enter” button until the

programmingiconbeginsashing.

2. Slowlypressandreleasethe“enter”buttonve(5)

times.

3. Only the will appear on the LCD display for

therst2minutesofoperation.Initializationisnow

complete.

TABLE 2

Air capacity correction factors (Multipliers)

INLET COMPRESSED AIR CONDITIONS

INLET INLET TEMPERATURES

PRESSURES 80°F 90°F 100°F 110°F 120°F

psig barg 27°C 32°C 38°C 43°C 49°C

50

80

100

125

150

175

200

3.4

5.5

6.9

8.6

10.3

12.1

13.8

1.35

1.50

1.55

1.63

1.70

1.75

1.80

1.05

1.17

1.23

1.31

1.37

1.42

1.47

0.84

0.95

1.00

1.07

1.13

1.18

1.22

0.69

0.79

0.82

0.91

0.95

0.99

1.03

0.56

0.66

0.70

0.74

0.80

0.84

0.89

COOLING MEDIUM*

AMBIENT

TEMPERATURE MULTIPLIER

°F °C

80

90

100

110

27

32

38

43

1.12

1.06

1.00

0.94

*Air-cooled models; water-cooled models use 1.15 multiplier if cooling water is

below 95°F (35°C).

12

ELECTRICAL SCHEMATIC

Models 1000 and 1250

Sheet 1 of 2

L1-5A

TB1-20

02

A

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

BCDEFGHJKLMN

L3

-Q00

-K62

-F11

M

L1-1

L2-1

L3-1

L1-1A

L2-1A

L3-1A

COMPRESSOR

460 VAC, 3 PH

Model 1000

-

4HP, 8.6 RLA

Model 1250

-

5HP, 10.7 RLA

TB1-1

TB1-2

TB1-3

TB1-PE

TB1-19

L2

L1

-K43

-F13

M

L1-3

L2-3

L3-3

L1-3A

L2-3A

L3-3A

FAN

1.25 KW

460 VAC

1.95 RLA

TB1-7

TB1-9

TB1-11

TB1-PE

HEATER

27 W, 460VAC

0.06A

-K62

1A

1A

1A

-F22A

-F22B

-F22C

L1-5

L3-5

L1-5

L2-5

40A

ELECTRICAL SUPPLY

480VAC

60Hz

3 PH / GND

TB1-PE

-F22

**MOUNTED

ON -T22

1.4

-

2A

(SET @ 2A)

(12 AWG)

(12 AWG)

(1O AWG)

(12 AWG)

TB1-PE

FU22.1

TB2-1

-T22

240/277/400/480/575 VAC PRIMARY

24/120 VAC SECONDARY

100VA

5A

FU22

SHT#2 4B

SHT#2 4N

24V

120V

H1

H2

H4

H5

H6

H3

X4

X2

X1

F

480V

400V

277V

240V

COM

575V

FU22.2

N

Model 1000: SET @ 9A

Model 1250: SET @ 10.7A

9

-

12.5A

13

ELECTRICAL SCHEMATIC

Models 1000 and 1250

Sheet 2 of 2

02

A

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

BCDEFGHJKLMNPQ

TB2-2

FU22.2

-S62

236

FAN CONTACTOR

SHT#1 26G

REFRIGERANT HI PRES.

REFRIGERANT HI PRES.

RELAY SHT#2 42C

SHT#1 60K SHT#1 58K

24VAC

TB2-2

1

-K43

TB2-32 TB2-1

-S43 -S43.1 32

2

PRES. 1 FAN 1 TEMP. 1 FAN 1

TB2-31 TB2-32

TB2-31

TB2-36

-K61

W16

W32

W31

W1

LINE NEUTRAL

W2

W27

W26

3

4

L

N

OV

IN1

PE

13

21

22

23

W30

W13

W14

5

-A51

-A55

26

W15

26

W10

8

TB2-8

-K61

W8

-K62 -F11

K62X-NO

26

W9

-K62

19

TB2-7

26

W11

9

TB2-9

26 -S67

W3

GND

W5

W4 RED

BLK

-B61

10

1125

25

EVAPORATOR TEMP SENSOR

-K62 COMPRESSOR CONTACTOR

SHT#1 16G, 48D

SHT#2 38C, 40D

COMPRESSOR ENERGIZED

HEATER ENERGIZED

DRAIN 1 ALARM

DRAIN 2 ALARM

REFRIGERANT HIGH PRESSURE

REFRIGERANT LOW PRESSURE

REMOTE

START/STOP

LOCAL/REMOTE

SELECTION

DRAIN TEST

PHASE

CHECK

ALARM A

COMPRESSOR STOP

EMM II

ALARM B

MONITORING

TB2-2

DRAIN COMMON

COMMON

TB2-26

TB2-21

TB2-22

TB2-23

TB2-10

TB2-11

TB2-13

SHT#1 16D

START/STOP

LOCAL REMOTE

** JUMPER FOR SINGLE DRAIN APPLICATION

2

1

TB2-1

PE

TB2-PE

TB2-2

TB2-5

TB2-19

TB2-4

TB2-3

TB10-1

TB2-PE

TB10-2

J2 9-PIN RS232

CABLE

STD DRAIN

-A51

OPTIONAL

CLSC DRAIN

-A55

26

NO

37

TB2-37

TB2-39

W33

COMMON

TB2-25

W29

25

25

W22 W23

L

N

OV

IN1

PE

-A55

W34

W35

W36

14

TB2-14

15

TB2-15

W17

NC

W18

C

W19 16

TB2-16

NO

17

TB2-17

18

TB2-18

W20

NC

W21

C

TB2-1

TB2-1

TB2-1

14

ELECTRICAL SCHEMATIC

Model 1500

Sheet 1 of 2

02

A

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

BCDE FGHJ KLMN PQ

L3

-Q00

-K62

-F11

M

L1-1

L2-1

L3-1

L1-1A

L2-1A

L3-1A

COMPRESSOR

460 VAC, 3 PH

7 HP, 12.9 RLA

TB1-1

TB1-2

TB1-3

TB1-PE

TB1-19

TB1-20

L2

L1

-K43

-F13

M

L1-3

L2-3

L3-3

L1-3A

L2-3A

L3-3A

FAN 1

1.05 KW

460 VAC

1.8 RLA

TB1-7

TB1-9

TB1-11

TB1-PE

HEATER

27 W, 460VAC

0.06A

-K62

1A

1A

1A

-F22A

-F22B

-F22C

L1-5

L3-5

L1-5

L2-5

40A

ELECTRICAL SUPPLY

480VAC

60Hz

3 PH / GND TB1-PE

-F22

**MOUNTED

ON -T22

M

FAN 2

1.05 KW

460 VAC

1.8 RLA

TB1-13

TB1-15

TB1-17

TB1-PE

11

-

16A

(SET @ 12.9A)

2.8

-

4A

(SET @ 3.6A)

(12 AWG)

(12 AWG)

(1O AWG)

(12 AWG)

-K45

L1-4A

L2-4A

L3-4A

TB1-PE

FU22.1

TB2-1

-T22

240/277/400/480/575 VAC PRIMARY

24/120 VAC SECONDARY

100VA

5A

FU22

SHT#2 4B

SHT#2 4N

24V

120V

H1

H2

H4

H5

H6

H3

X4

X2

X1

F

480V

400V

277V

240V

COM

575V

FU22.2

N

L1-5A

15

ELECTRICAL SCHEMATIC

Model 1500

Sheet 2 of 2

02

A

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

BCDE FGHJ KLMN PQ

TB2-2

FU22.2

-S62 -K61

236

36

FAN CONTACTOR 1

SHT#1 28G

REFRIGERANT HI PRES.

REFRIGERANT HI PRES.

RELAY, SHT#2 44C

SHT#1 68K SHT#1 66K

24VAC

TB2-2

1

TB2-2 FAN CONTACTOR 2

SHT#1 36G

32 -K43

TB2-1

35 -K45

TB2-1

-S43

2

PRES. 1 FAN 1

-S45

2

PRES. 1 FAN 2

TB2-31

-S43.1

TEMP. 1 FAN 1 TB2-32

TB2-34

-S45.1

TEMP. 1 FAN 2 TB2-35

TB2-36

W16

W32

W31

W1

LINE NEUTRAL

W2

W27

W26

3

4

L

N

OV

IN1

PE

-A51

-A55

13

21

22

23

W30

W13

W14

5

7

-A51

-A55

26

W15

26

W10

8

TB2-8

-K61

W8

-K62 -F11

K62X-NO

26

W9

-K62

19

TB2-7

26

W11

9

TB2-9

26 -S67

W3

GND

W5

W4 RED

BLK

-B61

10

1125

25

EVAPORATOR TEMP SENSOR

-K62 COMPRESSOR CONTACTOR

SHT#1 16G, 52D,

SHT#2 40C, 42D

COMPRESSOR ENERGIZED

HEATER ENERGIZED

DRAIN 1 ALARM

DRAIN 2 ALARM

REFRIGERANT HIGH PRESSURE

REFRIGERANT LOW PRESSURE

REMOTE

START/STOP

LOCAL/REMOTE

SELECTION

DRAIN TEST

PHASE

CHECK

ALARM A

COMPRESSOR STOP

EMM II

ALARM B

MONITORING

TB2-2

DRAIN COMMON

COMMON

TB2-26

TB2-21

TB2-22

TB2-23

TB2-10

TB2-11

TB2-13

SHT#1 16D

START/STOP

LOCAL REMOTE

** JUMPER FOR SINGLE DRAIN APPLICATION

2

1

TB2-1

PE

TB2-PE

TB2-2

TB2-5

TB2-19

TB2-4

TB2-3

TB10-1

TB2-PE

TB10-2

J2 9-PIN RS232

CABLE

STD DRAIN

CLSC DRAIN

OPTIONAL

26

NO

37

TB2-37

TB2-39

W33

COMMON

TB2-25

W29

25

25

W22 W23

L

N

OV

IN1

PE

-A55

W34

W35

W36

14

TB2-14

15

TB2-15

W17

NC

W18

C

W19 16

TB2-16

NO

17

TB2-17

18

TB2-18

W20

NC

W21

C

TB2-1

TB2-1

TB2-1

16

ELECTRICAL SCHEMATIC

Models 1750, 2000 and 2500

Sheet 1 of 2

02

A

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

BCDEFGHJ KLMNPQ

L3

-Q00

-K62

-F11

M

L1-1

L2-1

L3-1

L1-1A

L2-1A

L3-1A

COMPRESSOR

460 VAC, 3 PH

Models 1750, 2000: 8 HP, 15.7 RLA

Model 2500: 10 HP, 19.3 RLA

TB1-1

TB1-2

TB1-3

TB1-PE

TB1-19

TB1-20

L2

L1

2.8-4A

(SET @ 3.6A)

-K43

-F13

M

L1-3

L2-3

L3-3

L1-3A

L2-3A

L3-3A

FAN 1

1.05 KW

460 VAC

1.8 RLA

TB1-7

TB1-9

TB1-11

TB1-PE

HEATER

27 W, 460 VAC

0.06A

-K62

1A

-F22A

-F22B

-F22C

TB1-PE

FU22.1

TB2-1

-T22

240/277/400/480/575 VAC PRIMARY

24/120 VAC SECONDARY

100VA

L1-5

L3-5

L1-5

L2-5

40A

ELECTRICAL SUPPLY

480VAC, 60 Hz

3 PH / GND TB1-PE

5A

FU22

SHT#2 4B

SHT#2 4N

24V

120V

H1

H2

H4

H5

H6

H3

X4

X2

X1

F

480V

400V

277V

240V

COM

575V

-F22

**MOUNTED

ON -T22

FU22.2

M

FAN 2

1.05 KW

460 VAC

1.8 RLA

TB1-13

TB1-15

TB1-17

TB1-PE

(10 AWG)

(12 AWG)

(1O AWG)

(12 AWG)

-K45

L1-4A

L2-4A

L3-4A

14-20A

N

1A

1A

L1-5A

Models 1750, 2000: SET @ 15.7A

Model 2500: SET @ 19.3A

17

ELECTRICAL SCHEMATIC

Models 1750, 2000 and 2500

Sheet 2 of 2

02

A

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

BCDEFGHJ KLMNPQ

TB2-2

FU22.2

-S62 -K61

236

36

FAN CONTACTOR 1

SHT#1 26G

REFRIGERANT HI PRES.

RELAY, SHT#2 42C

SHT#1 60J SHT#1 58J

24VAC

TB2-2

1

TB2-2 FAN CONTACTOR 2

SHT#1 36G

-K43

TB2-1

-K45

TB2-1

-S43 32

2

PRES. 1 FAN 1

-S45 35

2

PRES. 1 FAN 2

TB2-31

-S43.1

TEMP. 1 FAN 1

-S45.1

TEMP. 1 FAN 2

TB2-32

TB2-34 TB2-35

W16

W32

W31

W1

LINE NEUTRAL

W2

W27

W26

3

4

L

N

OV

IN1

PE

-A51

-A55

13

21

22

23

W30

W13

W14

5

7

-A51

-A55

26

W15

26

W10

8

TB2-8

-K61

W8

-K62 -F11

K62X-NO

26

W9

-K62

19

TB2-7

26

W11

9

TB2-9

26 -S67

W3

GND

W5

W4 RED

BLK

-B61

10

1125

25

REFRIGERANT HI PRES.

EVAPORATOR TEMP SENSOR

-K62 COMPRESSOR CONTACTOR

SHT#1 14G, 48D

SHT#2 40C, 40D

COMPRESSOR ENERGIZED

HEATER ENERGIZED

DRAIN 1 ALARM

DRAIN 2 ALARM

REFRIGERANT HIGH PRESSURE

REFRIGERANT LOW PRESSURE

REMOTE

START/STOP

LOCAL/REMOTE

SELECTION

DRAIN TEST

PHASE

CHECK

ALARM A

COMPRESSOR STOP

EMM II

ALARM B

MONITORING

TB2-2

DRAIN COMMON

COMMON

TB2-26

TB2-21

TB2-22

TB2-23

TB2-10

TB2-11

TB2-13

SHT#1 16D

START/STOP

LOCAL REMOTE

** JUMPER FOR SINGLE DRAIN APPLICATION

2

1

TB2-1

PE

TB2-PE

TB2-2

TB2-5

TB2-19

TB2-4

TB2-3

TB10-1

TB2-PE

TB10-2

J2 9-PIN RS232

CABLE

STD DRAIN

CLSC DRAIN

OPTIONAL

26

NO

37

TB2-37

TB2-39

W33

COMMON

TB2-25

W29

25

25

W22 W23

L

N

OV

IN1

PE

-A55

W34

W35

W36

14

TB2-14

15

TB2-15

W17

NC

W18

C

W19 16

TB2-16

NO

17

TB2-17

18

TB2-18

W20

NC

W21

C

TB2-1

TB2-1

TB2-1

18

ELECTRICAL SCHEMATIC

Model 3000

Sheet 1 of 2

02

A

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

BCDEFGHJKLMN

L3

-Q00

22

-

32A

(SET @ 25.7A)

-K62

-F11

M

L1-1

L2-1

L3-1

L1-1A

L2-1A

L3-1A

COMPRESSOR

460 VAC, 3PH

13 HP, 25.7 RLA

TB1-1

TB1-2

TB1-3

TB1-PE

TB1-19

TB1-20

L2

L1

5.5

-

8A

(SET @ 7.2A)

-K43

-F13

M

L1-3

L2-3

L3-3

L1-3A

L2-3A

L3-3A

FAN 1

1.05 KW

460 VAC

1.8 RLA

TB1-7

TB1-9

TB1-11

TB1-PE

HEATER

27 W

460 VAC

0.06A

-K62

1A

1A

1A

-F22A

-F22B

-F22C

FU22.1

TB2-1

-T22

240/277/400/480/575 VAC PRIMARY

24/120 VAC SECONDARY

100VA

L1-5

L3-5

L1-5

L2-5

60A

ELECTRICAL SUPPLY

480VAC

60Hz

3 PH / GND TB1-PE

5A

FU22

SHT#2 4B

SHT#2 4N

24V

120V

H1

H2

H4

H5

H6

H3

X4

X2

X1

F

480V

400V

277V

240V

COM

575V

-F22

**MOUNTED

ON -T22

FU22.2

M

FAN 3

1.05 KW

460 VAC

1.8 RLA

(10 AWG)

(12 AWG)

(8 AWG)

(12 AWG)

-K45

M

L1-4A

L2-4A

L3-43A

FAN 2

1.05 KW

460 VAC

1.8 RLA

TB1-13

TB1-15

TB1-17

TB1-PE

M

FAN 4

1.05 KW

460 VAC

1.8 RLA

TB1-PE

L1-5A

19

ELECTRICAL SCHEMATIC

Model 3000

Sheet 2 of 2

02

A

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

B C D E F G H J K L M N P Q

TB2-2

FU22.2

W16

W32

W31

W1 LINE

NEUTRAL

W2

W27

W26

3

4

L

N

OV

IN1

PE

-A51

-A55

13

21

22

23

W30

-S62 -K61

W13

W14

5

7

-A51

-A55

26

W15

26

W10

8

TB2-8

-K61

W8

-K62 -F11

K62X-NO

26

W9

-K62

19

TB2-7

26

W11

9

TB2-9

26 -S67

W3 GND

W5

W4 RED

BLK

-B61

10

1125

25

2 36

36

FAN CONTACTOR 1

SHT#1 28G

REFRIGERANT HI PRES.

REFRIGERANT HI PRES.

RELAY, SHT#2 42C

EVAPORATOR TEMP SENSOR

-K62 COMPRESSOR CONTACTOR

SHT#1 16G, 48D

SHT#2 40C, 40D

COMPRESSOR ENERGIZED

HEATER ENERGIZED

DRAIN 1 ALARM

DRAIN 2 ALARM

REFRIGERANT HIGH PRESSURE

REFRIGERANT LOW PRESSURE

REMOTE

START/STOP

LOCAL/REMOTE

SELECTION

DRAIN TEST

PHASE

CHECK

ALARM A

COMPRESSOR STOP

EMM II

SHT#1 60J SHT#1 58J

24VAC

TB2-2

ALARM B

MONITORING

TB2-2

DRAIN COMMON

COMMON

TB2-26

TB2-21

TB2-22

TB2-23

TB2-10

TB2-11

TB2-13

SHT#1 16D

START/STOP

LOCAL REMOTE

** JUMPER FOR SINGLE DRAIN APPLICATION

2

1

TB2-1

PE

TB2-PE

TB2-2

TB2-5

TB2-19

TB2-4

TB2-3

1

TB10-1

TB2-PE

TB10-2

TB2-2 FAN CONTACTOR 2

SHT#1 40G

-K43

TB2-1

-K45

TB2-1

-S43 32

2

PRES. 1 FAN 1 & 3

-S45 35

2

PRES. 1 FAN 2 &4

TB2-31

-S43.1

TEMP. 1 FAN 1

-S43.2

TEMP. 1 FAN 3

-S45.1

TEMP. 1 FAN 2

-S45.2

TEMP. 1 FAN 4

TB2-32

TB2-34 TB2-35

J2 9-PIN RS232

CABLE

STD DRAIN

CLSC DRAIN

OPTIONAL

26

NO

37

TB2-37

TB2-39

W33

COMMON

TB2-25

W29

25

25

W22 W23

L

N

OV

IN1

PE

-A55

W34

W35

W36

14

TB2-14

15

TB2-15

W17

NC

W18

C

W19 16

TB2-16

NO

17

TB2-17

18

TB2-18

W20

NC

W21

C

TB2-1

TB2-1

TB2-1

20

1750-3000 scfm

DIMENSIONS / WEIGHTS

1000 scfm

1250-1500 scfm

C

B

E

OUTLET

FD

INLET

A

LEFT SIDE VIEW FRONT VIEW RIGHT SIDE VIEW

TOP VIEW

C

B

ED

F

INLET

OUTLET

A

LEFT SIDE VIEWFRONT VIEW RIGHT SIDE VIEW

TOP VIEW

B

C

E

INLET

DF

OUTLET

A

LEFT SIDE VIEW FRONT VIEW RIGHT SIDE VIEW

TOP VIEW

Dimensions in (mm)

Model

Height

(A)

Width

(B)

Depth

(C) (D) (E) (F)

Weight

Lb. (kg)

Inlet/Outlet

Connections

1000

1250

1500

85.1/8 (2162)

85.1/8 (2162)

85.1/8 (2162)

48.1/2 (1232)

48.1/2 (1232)

48.1/2 (1232)

40.3/4 (1035)

50.3/4 (1289)

50.3/4 (1289)

12.1/2 (318)

13.1/4 (337)

13.1/4 (337)

12.7/8 (327)

11.1/4 (286)

11.1/4 (286)

8.3/4 (222)

8.1/2 (216)

8.1/2 (216)

1146 (520)

1521 (690)

1547 (702)

3” ANSI Flg.

4” ANSI Flg.

4” ANSI Flg.

1750

2000

2500

3000

85.1/8 (2162)

85.1/8 (2162)

85.1/8 (2162)

85.1/8 (2162)

55.1/8 (1400)

55.1/8 (1400)

55.1/8 (1400)

55.1/8 (1400)

59.3/8 (1508)

59.3/8 (1508)

59.3/8 (1508)

59.3/8 (1508)

13.1/4 (337)

13.1/4 (337)

13.1/4 (337)

13.1/4 (337)

31.1/4 (794)

31.1/4 (794)

31.1/4 (794)

31.1/4 (794)

9.1/8 (232)

9.1/8 (232)

9.1/8 (232)

9.1/8 (232)

1940 (880)

1986 (901)

2315 (1050)

2646 (1200)

6” ANSI Flg.

6” ANSI Flg.

6” ANSI Flg.

6” ANSI Flg.

NOTE: Dimensions and weights are for reference only. Request certified drawings for construction purposes.

This manual suits for next models

7

Table of contents

Other SPX Dehumidifier manuals

SPX

SPX Hankison HPRP Series User manual

SPX

SPX RDH-HP Series User manual

SPX

SPX HPD Series User manual

SPX

SPX HANKISON HES Series User manual

SPX

SPX HCD Series User manual

SPX

SPX HANKISON HIT Series User manual

SPX

SPX Hankison GCU Series User manual

SPX

SPX DELAIR QD 90 User manual

SPX

SPX Pneumatic Products IBP500 User manual