7

Installing the Soft Shield Elite

New systems come with the cartridges and outlet connector pre-installed. Installer

should verify this during installation. When changing cartridges reverse installation

procedure and note items 6 & 7.

1. Please conrm that all items required are included in the kit ready for

assembly and remove from carton

2. Find a suitable location for the installation keeping in mind access to the

incoming water supply and the treated supply to the home, restaurant or

foodservice equipment.

3. The system must stand upright in the desired location and secured using

the wall mounting bracket provided where possible.

4. Take the two threaded Adapters (Item 5) and insert them into the inlet and

outlet of the Soft Shield Housing (Item 1) as shown in Diagram A.

5. Secure these adapters with the two red adapter Locking Pins (Item 6) as

shown in Diagram A.

6. Take the Sediment/Carbon Filter cartridge (Item 7) and place it within the

Softshield Housing (Item 1) as shown in Diagram B.

7. Take the Aquablu Scale Elimination cartridge (Item 8) and secure it within

the centre of the Sediment/Carbon Filter cartridge (Item 7) as shown in

Diagram C.

8. Take the Outlet Connector (Item 4) and install it as shown in Diagram D.

9. Take the Head Assembly (Item 2) and screw this onto the Housing (Item 1)

as shown in Diagram E.

10. To tighten take the Multifunction Tool (Item 9) and tighten the Head

Assembly as shown in Diagram E by tightening in a clockwise direction –

DO NOT OVER TIGHTEN.

11. Using PTFE tape connect incoming water supply to the inlet of the Soft

Shield Elite system and connect to the outlet as required to service the

property.

12. Turn on water supply and check for leaks. Open rst cold water tap on the

system to release any air, and run the system for 5 minutes before putting

into service.

Introduction

Thank you for your purchase of the TurboTAC salt-

free limescale prevention and water ltration system.

This water treatment system has been designed and

tested to provide you with high quality drinking water

and limescale prevention for years to come.

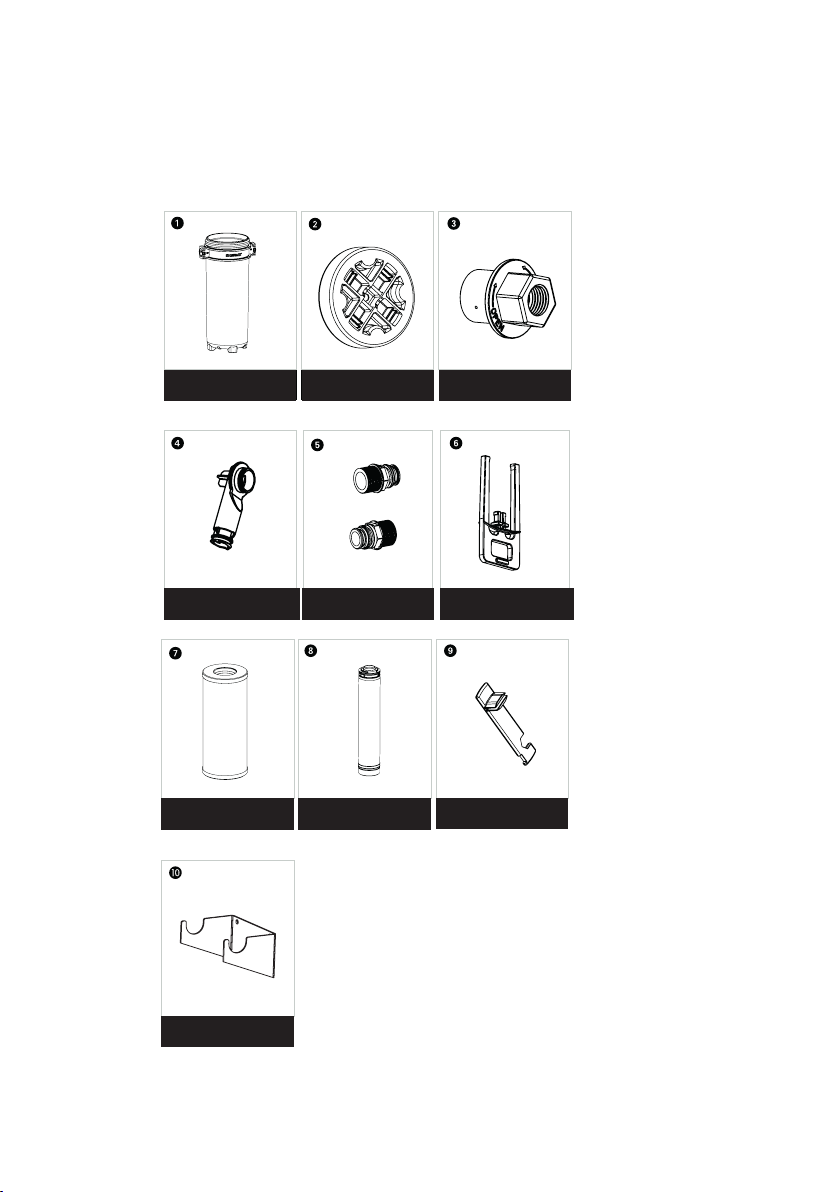

System Parts

Installation Instructions

OneFlow+ Housing

Outlet Connector

OneFlow+ Head Assembly

1 MPT Threaded Inlet /

Outlet Adapters (x2)

Pressure Relief Valve

Inlet / Outlet red Adapter

Locking Pins (x2)

Sediment / Carbon Filter

Cartridge (20 microns)

OneFlow+ Scale Reduction

(TAC) Cartridge Multifunction Tool

Mounting Bracket

2

Introduction

Thank you for your purchase of Watts OneFlow+ salt-free scale

prevention and water ltration system. This Watts water treatment

system has been designed and tested to provide you with high qual-

ity drinking water fand scale prevention for years to come.

Installation Instructions

New systems come with the cartridges and outlet connector pre-installed. Installer

should verify this during installation.

1. Please confirm that all items required are included in the kit ready for assembly

and remove from carton.

2. Find a suitable location for the OneFlow+ system keeping in mind access to the

water supply and delivery to the home, restaurant or foodservice equipment.

3. The system can stand upright in the desired location without the need to affix

to a wall with a mounting bracket. However, a mounting bracket is available as a

separate part (Item 10)

4. Take the two 1”MPT Threaded Adapters (Item 5) and insert them into the inlet and

outlet of the OneFlow+ Housing (Item 1) as shown in Diagram A.

5. Secure these adapters with the two red adapter Locking Pins (Item 6) as shown in

Diagram A.

6. Take the Sediment/Carbon Filter cartridge (Item 7) and place it within the One-

Flow+ Housing (Item 1) as shown in Diagram B.

7. Take the OneFlow+ Scale reduction cartridge (Item 8) and secure it within the

centre of the Sediment/Carbon Filter cartridge (Item 7) as shown in Diagram C.

8. Take the Outlet Connector (Item 4) and install it as shown in Diagram D.

9. Take the OneFlow+ Head Assembly (Item 2) and screw this onto the OneFlow+

Housing (Item 1) as shown in Diagram E.

NOTICE

10. To tighten take the Multifunction Tool (Item 9] and tighten the Head Assembly as

shown in Diagram E by tightening in a clockwise direction – DO NOT OVER TI GHTEN

11. Using plumbing tape connect water supply to the inlet of the OneFlow+ system

and connect to the outlet of the OneFlow+ System as required.

12. Turn on water supply and check for leaks.

Diagram A

Diagram B

Diagram C

Diagram D

CLOSE

Diagram E

Diagram F

OPEN

Diagram G

Diagram H

OneFlow+ System Parts

NOTICE

IOM-WQ-OneFlow+.indd 2 10/15/2015 11:22:12 PM

Housing Head Assembly Pressure Relief Value

Outlet Connector Threaded Inlet / Outlet

Adapters (x2)

Inlet / Outlet Red Adapter

Looking Pins (x2)

Sediment / Carbon Filter

Cartridge (20 micorns)

Scale Reduction

(TAC) Cartridge Multifunction Tool

Mounting Bracket

New systems come with the cartridges and outlet connector pre-installed. Installer

should verify this during installation. When changing cartridges reverse installation

procedure and note items 6 & 7.

1. Please conrm that all items required are included in the kit ready for assembly and

remove from carton.

2. Find a suitable location for the installation keeping in mind access to the incoming

water supply and the treated supply to the home, restaurant or foodservice

equipment.

3. The system must stand upright in the desired location and secured using the wall

mounting bracket provided where possible.

4. Take the two threaded Adapters (Item 5) and insert them into the inlet and outlet of

the TurboTAC Housing (Item 1) as shown in Diagram A.

5. Secure these adapters with the two red adapter Locking Pins (Item 6) as shown in

Diagram A.

6. Take the Sediment/Carbon Filter cartridge (Item 7) and place it within the TurboTAC

Housing (Item 1) as shown in Diagram B.

7. Take the Next TAC Scale reduction cartridge (Item 8) and secure it within the centre

of the Sediment/Carbon Filter cartridge (Item 7) as shown in Diagram C.

8. Take the Outlet Connector (Item 4) and install it as shown in Diagram D.

9. Take the Head Assembly (Item 2) and screw this onto the Housing (Item 1) as

shown in Diagram E.

10. To tighten take the Multifunction Tool (Item 9] and tighten the Head Assembly as

shown in Diagram E by tightening in a clockwise direction – DO NOT OVER TIGHTEN

11. Using PTFE tape connect incoming water supply to the inlet of the TurboTAC

system and connect to the outlet as required to service the property.

12. Turn on water supply and check for leaks. Open rst cold water tap on the system

to release any air, and run the system for 5 minutes before putting into service.

OneFlow+ Housing

Outlet Connector

OneFlow+ Head Assembly

1 MPT Threaded Inlet /

Outlet Adapters (x2)

Pressure Relief Valve

Inlet / Outlet red Adapter

Locking Pins (x2)

Sediment / Carbon Filter

Cartridge (20 microns)

OneFlow+ Scale Reduction

(TAC) Cartridge Multifunction Tool

Mounting Bracket

2

Introduction

Thank you for your purchase of Watts OneFlow+ salt-free scale

prevention and water ltration system. This Watts water treatment

system has been designed and tested to provide you with high qual-

ity drinking water fand scale prevention for years to come.

Installation Instructions

New systems come with the cartridges and outlet connector pre-installed. Installer

should verify this during installation.

1. Please confirm that all items required are included in the kit ready for assembly

and remove from carton.

2. Find a suitable location for the OneFlow+ system keeping in mind access to the

water supply and delivery to the home, restaurant or foodservice equipment.

3. The system can stand upright in the desired location without the need to affix

to a wall with a mounting bracket. However, a mounting bracket is available as a

separate part (Item 10)

4. Take the two 1”MPT Threaded Adapters (Item 5) and insert them into the inlet and

outlet of the OneFlow+ Housing (Item 1) as shown in Diagram A.

5. Secure these adapters with the two red adapter Locking Pins (Item 6) as shown in

Diagram A.

6. Take the Sediment/Carbon Filter cartridge (Item 7) and place it within the One-

Flow+ Housing (Item 1) as shown in Diagram B.

7. Take the OneFlow+ Scale reduction cartridge (Item 8) and secure it within the

centre of the Sediment/Carbon Filter cartridge (Item 7) as shown in Diagram C.

8. Take the Outlet Connector (Item 4) and install it as shown in Diagram D.

9. Take the OneFlow+ Head Assembly (Item 2) and screw this onto the OneFlow+

Housing (Item 1) as shown in Diagram E.

NOTICE

10. To tighten take the Multifunction Tool (Item 9] and tighten the Head Assembly as

shown in Diagram E by tightening in a clockwise direction – DO NOT OVER TI GHTEN

11. Using plumbing tape connect water supply to the inlet of the OneFlow+ system

and connect to the outlet of the OneFlow+ System as required.

12. Turn on water supply and check for leaks.

Diagram A

Diagram B

Diagram C

Diagram D

CLOSE

Diagram F

OPEN

Diagram G

Diagram H

OneFlow+ System Parts

NOTICE

IOM-WQ-OneFlow+.indd 2 10/15/2015 11:22:12 PM

Innovative purication solutions

www.aquablu.com