_________________________________________________________________________________________

3

Never use damaged equipment, doing so

mayresultinaninoperativeorhazardousinstallation.

Discontinueuseofthesteamgeneratorandcontrolifthe

steamgeneratororcontrolaredamagedorotherwisenotfunc-

tioningproperly.Doingsomayresultinaninoperativeorhaz-

ardousinstallation

ELECTRICALSHOCKHAZARD.$TXDVWHDPsteamgeneratorsare

connectedto240Vline

voltageandcontainliveelectricalcom-

ponents.Allinstallationandservicetobeperformedbyquali-

fedandlicensedelectriciansandplumbersonly.Installationor

servicebyunqualifiedpersonsorfailuretouse"RVBTUFBN

partsmayresultinpropertydamageorin a hazardous

condition.

Do Not alter or modify any !QUASTEAM prod-

uct. Doing so may result in an inoperable or hazardous

installation and will void the warranty

BeforeInstalling

CarefullyinspecttheCTsteamgeneratorandpackagingfor

shippingdamage.Intheeventofshippingdamage,please

contactthecarrierforclaiminformation.Ourcustomer

servicedepartmentcanassistyouwithanymissingor

damagedparts.

Readtheseinstructionsbeforeinstallationorservice.

Althoughthissteamgeneratorhasbeenfullyqualifiedfor

shipment,thefollowingmustbereviewedforproper,safe

andenjoyablesteambathing:

1. Verify that the model and accessories specications are

correct for the incoming line voltage.

2. Insure steambath generator has been correctly sized for

Steam Room Guidelines

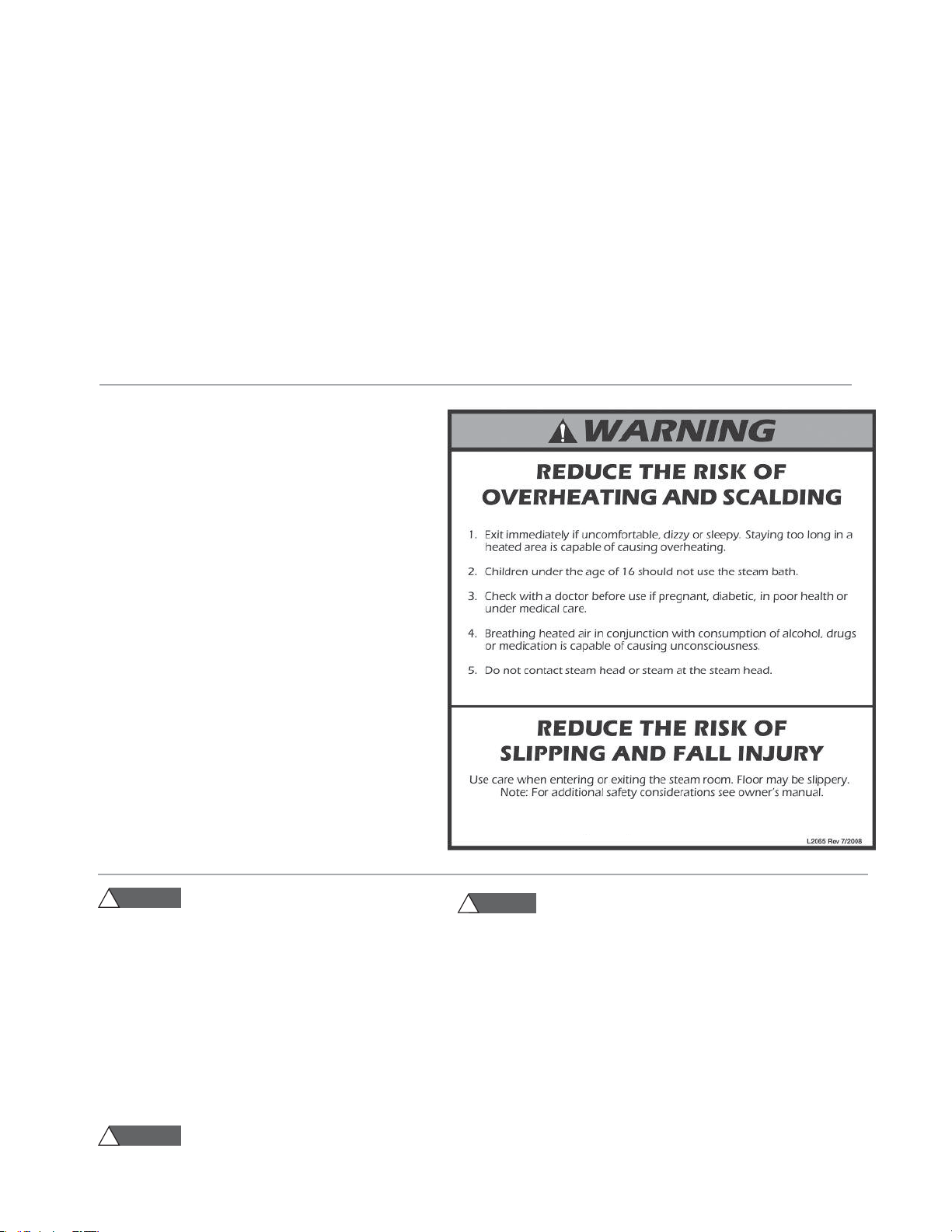

1. Steam room must be completely enclosed, with full

walls, door, oor and ceiling.

2. It is recommended that a gasketed door is used for

steam containment.

3. If tile-type or other smooth surfaced ooring is used

provide suitable anti-skid strips or equivalent, to

prevent a slipping hazard.

4. Check the suitability of any materials with the

manufacturer. Walls and ceilings must be constructed

of water-resistant, non-corrosive surface, such as tile,

marble, molded acrylic, or other non-porous material.

5. The ceiling should be sloped to prevent dripping of

condensate.

6. Provide a oor drain.

7. No heating, venting or air conditioning devices

should be installed inside the steam room.

8. Steam room tile construction information is available

from the Tile Council of America, Inc. by purchasing

the TCA Handbook for Ceramic Tile Installation.

Tel. (864) 646-8453 or www.tileusa.com.

9. Windows that are part of the steam room should be

double paned and tempered safety glass.

10. Limit steam room ceiling height to 8 feet. Exceeding

8 feet may require a higher-rated steam generator.

thesteambathroom.Payparticularattentiontoroom

volumeandconstruction.

Marbleorglasswallsorceilings“enlarge”theroom’ssize

requiring a generatorlargerthanonebasedonlyonthe

room’scubicfoot(LxHxW)volume.

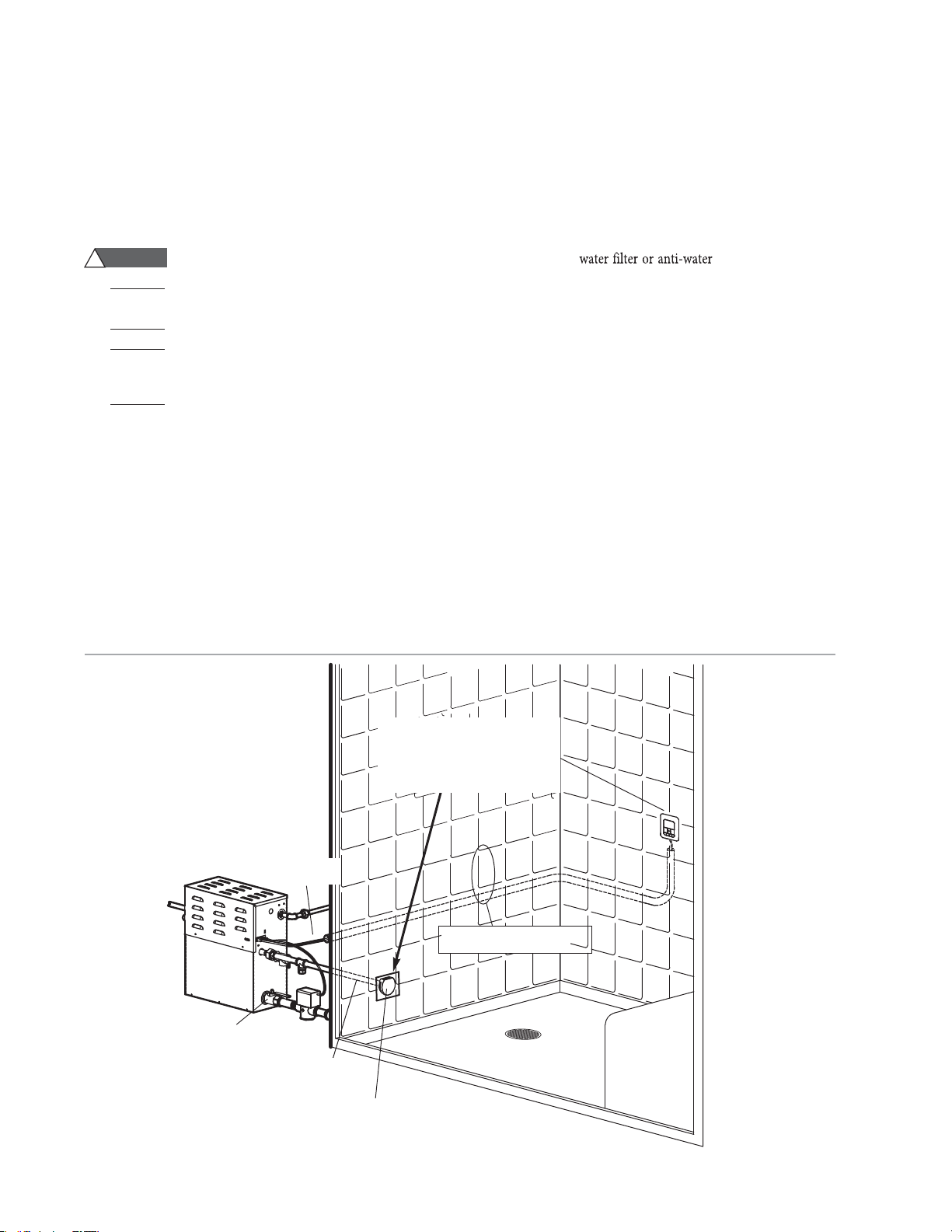

Thephysicalsizeoftheunit,clearanceforplumbing

servicing,anditsdistancefromthesteamroommustall

beconsideredbeforefinalinstallation.

Consideranycontrolsandaccessoriesbeforeinitiating

installation.ReadtheInstallationandOperationManual

ofallcontrolsandaccessories

WARNING

!

WARNING

!

!

CAUTION

Ifacrylic,berglassorothernon-heatresistantmaterialsare

used as part of the steam room enclosure. Consult with the material

manu-facture and see pg. 6, “Installing the Steamhead"for additional

details.

IMPORTANT NOTES:

This document contains important safety, operation and maintenance

infor-mation. Leave this document with the club/spa management.

Do not discard this document.

The following general information should be used in conjunction with con-

sultations with an architect, designer and contractor in determining

factors necessary in providing asuitable and safe steam room.

"RVBTUFBN BSF JOUFOEFE UP CF PQFSBUFE XJUI / BOE BSF UP CF

JOTUBMMFE TUSJDUMZ JO BDDPSEBODF XJUI UIF TQFDJGJD JOTUSVDUJPOT DPOUBJOFE JO UIJT

NBOVBMBOEBTTVQQMJFEJOUIFNBOVBMTQSPWJEFEXJUIUIFDPOUSPMTPSBDDFTTPSJFT