9

Water temperature not less than +5 and not more than

+38°C.

Sewerage

The unit drain must be routed to a waste water outlet,

such as a drain or washing machine drain, in accordance

with all local and national plumbing codes. An air gap or

siphon must be provided to prevent backflow (see the

“Installation and commissioning step by step” section).

Power supply

The power supply is designed for mains voltage of

220VAC with a frequency of 50 Hz. If there is a possibil-

ity of voltage deviation from the specified values by more

than 5–10%, use a voltage stabilizer. This will prevent

malfunctions and failure of both the power supply and the

electronic components of the softener.

ATTENTION! It is not recommended to separately con-

nect the softener to uninterruptible power supplies, as

this may cause failures in the regeneration process-

es. Connection is only possible in conjunction with

apumping station.

If you have any questions, please contact support. For

support information, see the General Information section

and the warranty card.

Step-by-step

instructions for

installing a softener

The softener connection must be made in accordance

with local plumbing codes.

The connection, setup and operation of the device must be

carried out within the limits of operation specified in this

manual. Failure to follow these guidelines may reduce flush

-

ing efficiency and result in softener malfunction or failure.

How to do:

• The softener must be installed after the hydraulic

accumulator tank and pump control automation sys-

tems.

• The softener must be installed in front of the water

heater and other appliances that consume water.

• The softener must be installed at least1m from heat-

ing appliances.

• It is not recommended to install the softener on

aheated floor, as this may cause excessive evapora-

tion from the brine tank and fouling of the softener

surfaces with salt crystals.

• Water for watering a lawn or garden does not require

softening and filtration, so this water can be drained

before the softener.

• When connecting the softener, it is recommended to

provide a bypass valve - “bypass” (see fig. 5). The by-

pass valve will simplify the maintenance of the soften-

er and will provide the supply of unsoftened water in

case of emergency when the softener is dismantled.

It is also recommended to drain the first portions of

contaminated water through the bypass after mainte-

nance work on the well, water supply or pump.

• If the length of the pipe between the softener and the

water heater is less than 3m, it is recommended to

install a non-return valve on this line as close as pos-

sible to the water heater. Make sure the water heater

is set to the correct temperature and the safety valve

is correct and in good working order.

You cannot do:

• Install and operate the softener in a room where the

temperature can drop below +5°C.

• Install and operate the softener in a room with humid-

ity over 70%.

• Install the softener near heating appliances.

• Connect the softener to the water supply in the op-

posite direction.

Step 1. Prepare a place for connection

• Turn off the power and water supply to the water

heater. For gas water heaters, additionally turn the

gas valve to the “Maintenance” or “Off” position. (See

instructions for your water heater).

• Turn off the water supply. Open hot and cold water

taps to relieve pressure in the lines. Check the water

supply for lime deposits, rust or other contaminants.

Clean or replace clogged plumbing.

• Organize the insertion point of the softener, according

to fig.3 so as to prevent axial distortions and tensions

during installation, as this can lead to damage to the

bypass assembly or softener valve.

• Arrange an electrical outlet at a distance of no more

than 2m.

NOTE: The bore diameter of the pipe from the accumula-

tor tank to the softener must be at least 3/4".

Step 2: Connect the softener to the water supply

The softener must be connected to the water line in ac-

cordance with national and local building, plumbing, and

electrical codes.

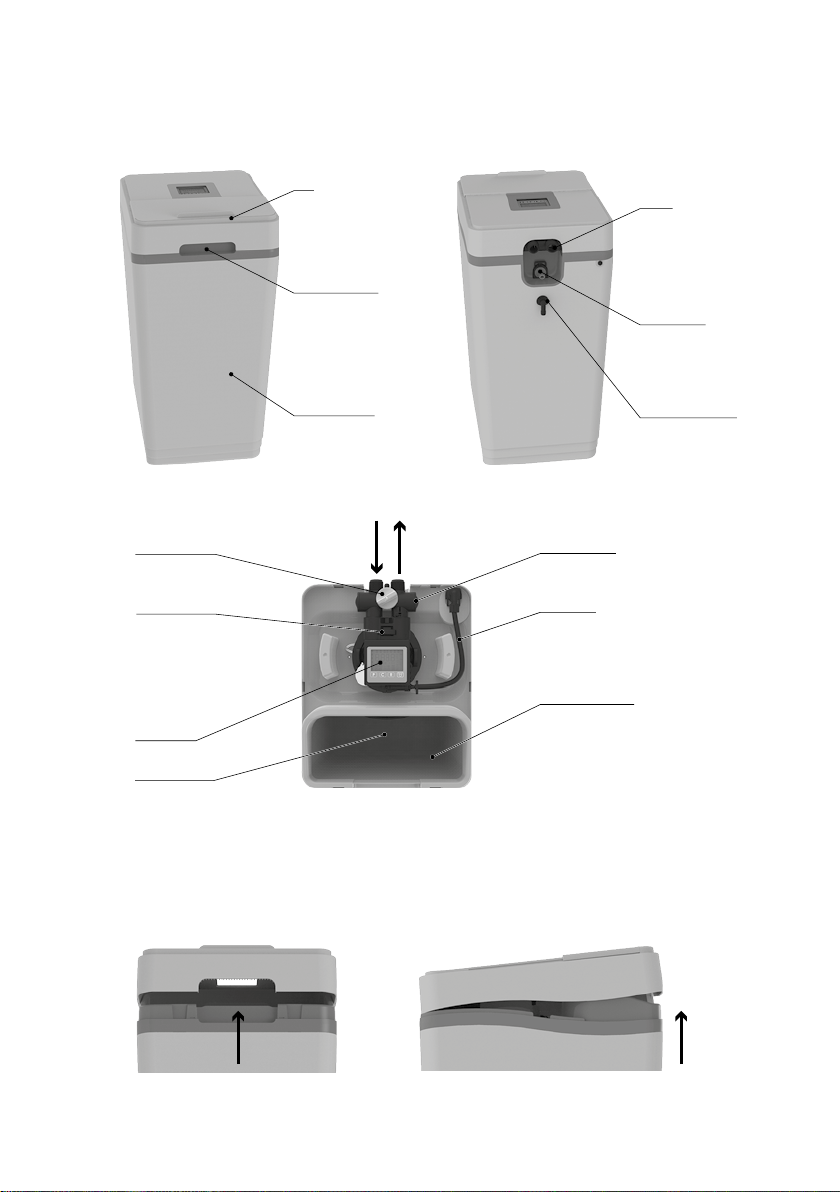

• Remove the softener cover by grabbing either the

front or the rear of the cover and pulling it straight up.

• Empty the salt compartment from all packaging and

installation materials.

• Make sure that the shims are inserted into the union

nuts of the flexible hoses. Connect the softener to the

water supply using flexible hoses.