10

Assurance & After Service

Thank you for choosing our product. Our product is produced strictly

under our regulations and quality control. However, if any of the

defects, related with our production processes, is found, our assurance

covers, according to the below conditions.

1. To repair:

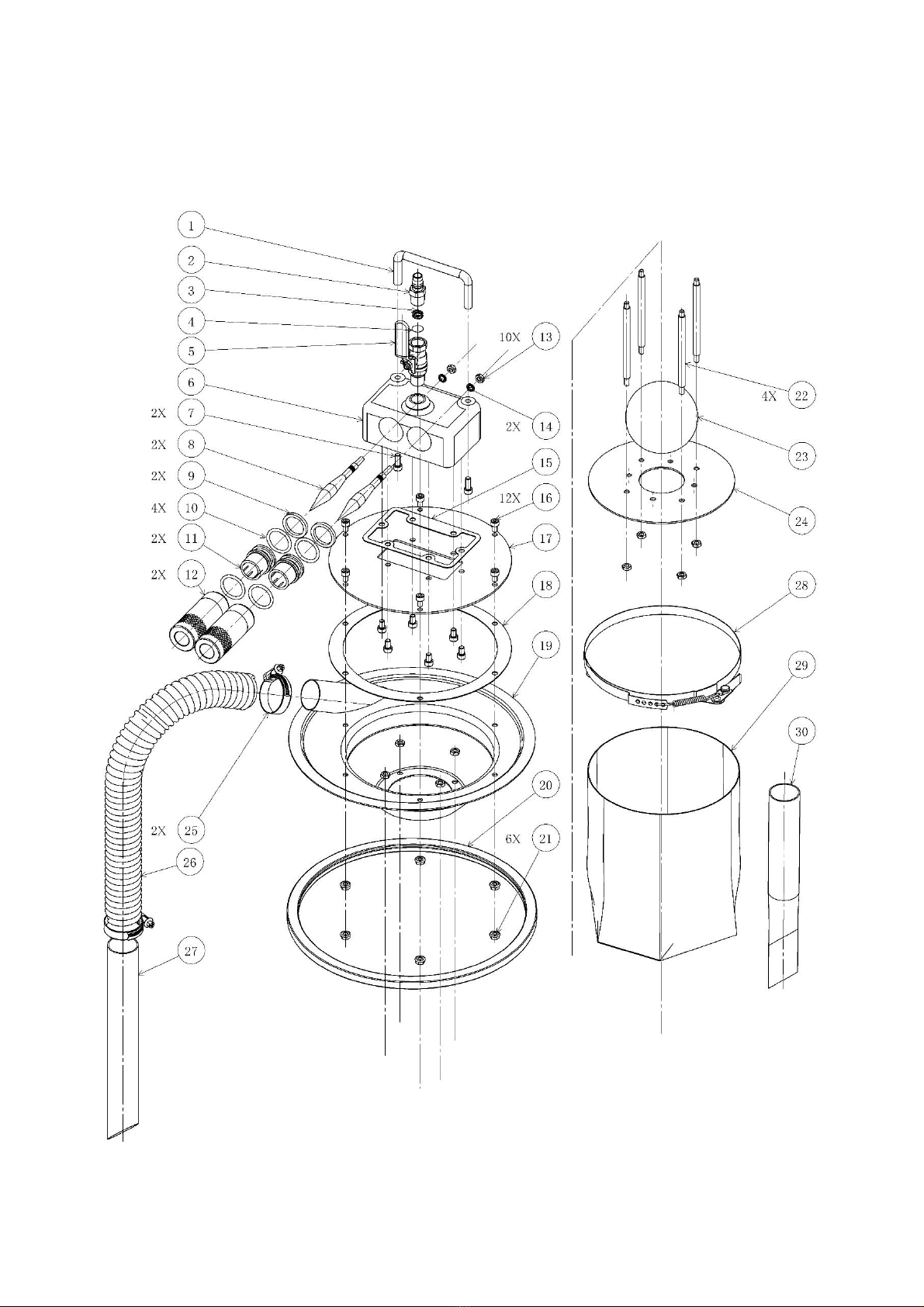

To order the parts or request for repair, inform us Part No., Mfg No.,

the purchased date with the receipt and then contact the purchased shop.

2. Within 12 months after the purchased date, if the below case* happens, we will

repair it at free of charge.

* Despite of regular maintenance and/or inspection specified in Manual, if

the trouble or damage happens due to the defect of our design or assembling,

within 12 months from the purchased date.

※However, we are not responsible for all and any related expenses or other damages

related with the above trouble and/or damage due to the defect of the product.

※When the free repair is taken care, if the part replacement is judged necessary

by us, as the consumables, the expenses for such replaced parts shall be borne

by the user.

3. If the assurance period of 12 months is over, or the above assurance condition

does not meet even within the assurance period of 12 months, the repairing expenses

shall not be covered by us, but borne by the user.

(Also, in case our product is applied to other manufacturer’s product, we take

no responsibility and our assurance cannot be applied)

4. In any case, delivery cost both to us and from us shall be borne by the user/

customers.

5. Exception from our responsibility (even within 12 months from purchased date)

①Any problems, due to wrong handling (not following our Manual)

②Any problems, due to repair, disassemble or remodel by a third party.

③Any problems, due to improper storing or improper maintenance.

④Any problem, without evidence to show the purchase of our product, such

as invoice or receipt etc.

⑤Unusual part consumption, due to heavy uses.

Contact the below for any question/request on the repair or after-service

within assurance period.