9

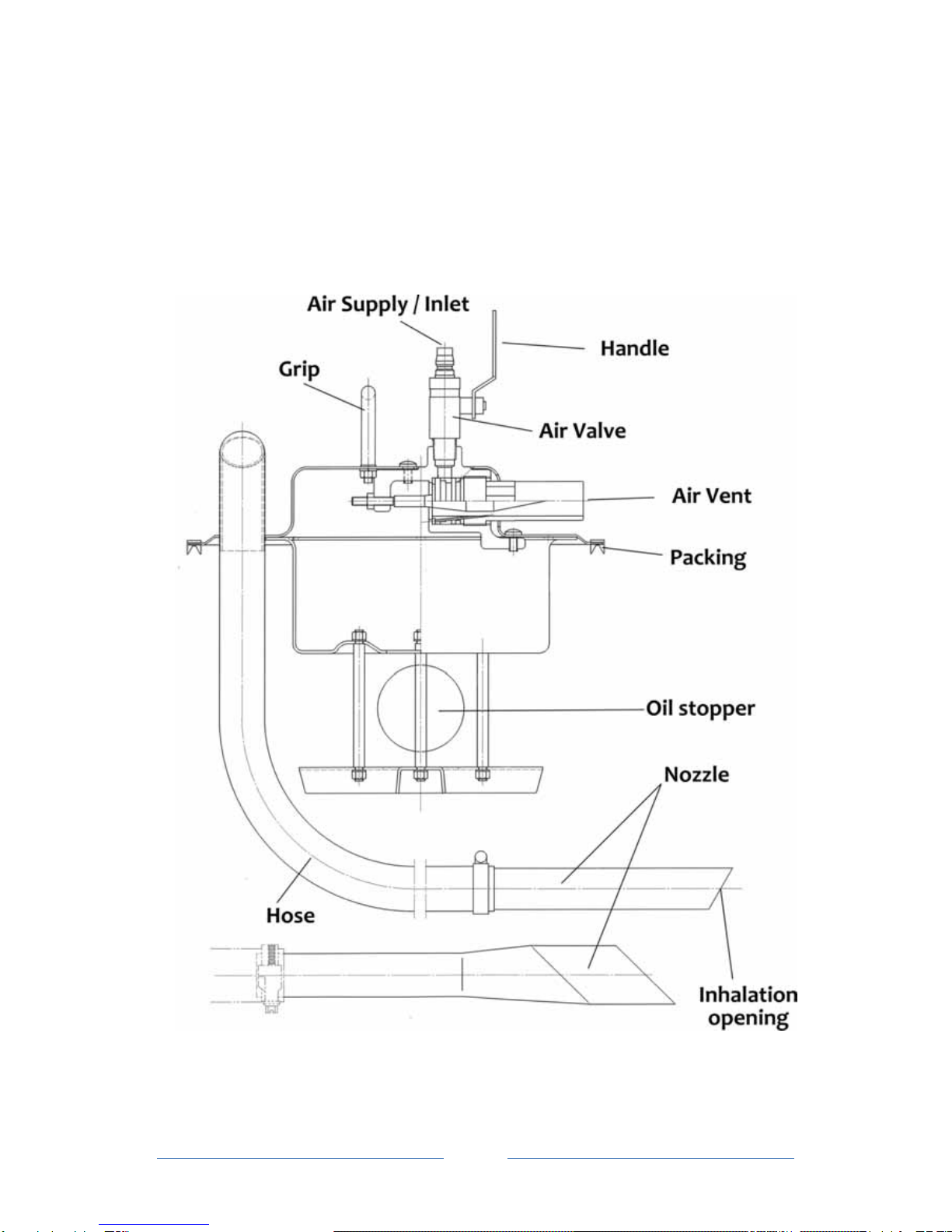

zUsage and handling

¾Usage conditions

Item Condition Details

Compressor outlet pressure >3.7 Kw (5PS) -

Injected air pressure 0.4-0.6 MPa If you use higher

pressure, please use the

Safety Valve;

nevertheless, always

remember about the

prescribed compressor

pressure range.

Air connection part Air coupler Use a socket and a hose

with a diameter over

3/8’’(inner diameter is 7

mm)

Pail can Attached An equivalent container

(mouthpiece diameter,

thickness material) can

be used as well.

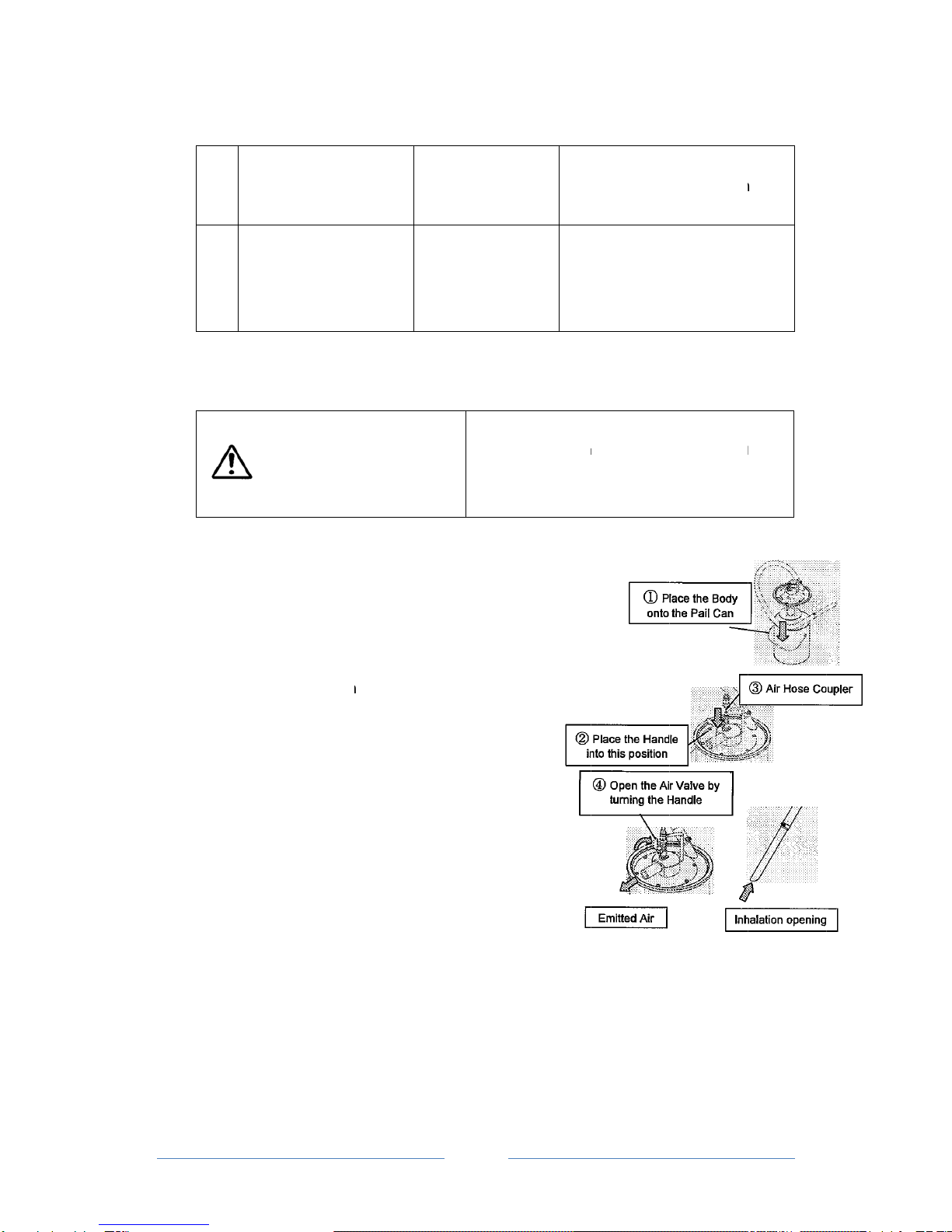

¾Check points (before usage)

Control point Status check Measures

①Inserted air pressure 0.4-0.6 MPa In case of pressure higher than

0.6 MPa, use a safety valve.

Fix it within the allowed

②Body In case of damage Visually check if device’s main

body is not damaged. Replace

if necessary.

③Packing In case of damage Visually check if the packing is

not damaged. Replace if

necessary.

④Hose In case of damage Visually check if the hose is

not damaged. Replace if

necessary.