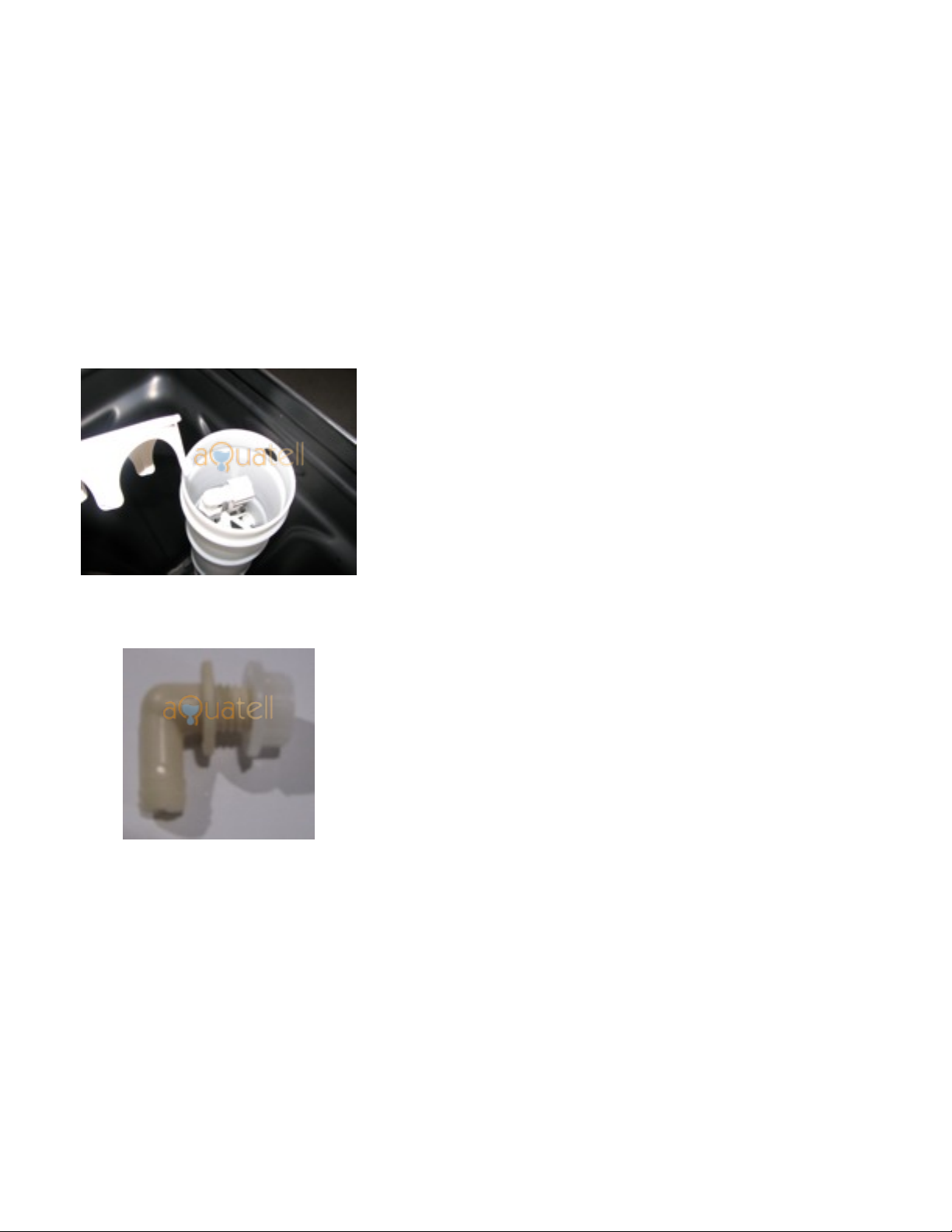

Overflow Bulkhead Fitting Funnel Drain Line Barb

Putting it all together - Overview

Once you’ve identified all of the components of your softener, you’re ready to begin the

installation. First, you’ll want to locate a good spot for your softener. All parts of your water

softener should be located in a protected, dry, level, non-freezing area. The water softener needs

to be located in very close proximity to your water main, and also needs to be located close to a

drain. Suitable drains include a floor drain, sump pit, washing-machine drain, or (where

regulations permit) an outside downspout or gutter drain. It’s important that you identify and

follow any local plumbing codes for the installation of your softener.

The drain line can be routed down to the floor or overhead. Whichever method is used please

ensure that all turns are gradual to prevent kinking in the line. Be sure to secure the drain line in

place as the pressure of the draining softener will move an unsecured line.

The softener you have purchased requires power in order to operate the valve. Ideally, you

should position the water softener a few feet from a power outlet. aQuatell recommends that all

water purification equipment, including softeners, be plugged into a Ground Fault Circuit

Interrupter (GFCI) outlet.

Check that the resin tank is sitting flat in the black plastic boot on the bottom of the tank. If the

boot appears to be on an angle push down on the resin tank and rock the tank very slightly back

and forth to lower the resin tank fully into the boot.

Putting it all together - The Softening Tank

The softening tank houses the resin and is where the softening of your water occurs. The

softening tank is the cylindrical tank with a threaded opening at the top. Set the softening tank in

the desired location. Insert the riser tube into this tank so that the slotted basket is at the bottom

of the softening tank. At the open end of the riser tube cover the opening with a piece of tape.

Now place the funnel in the opening of the softening tank and add the resin:

Page 3

Fleck 5600SXT U.S. V1.1

Copyright aQuatell Inc 2010