4

Clicking sound

This sound is the oscillator moving back and forth in

the oscillator chamber. The best speed for it is about

500 oscillations per minute. The vibration created by

the oscillator moves the bristles and the cleaner. If the

oscillator is running too fast, the cleaner will have a

tendency to climb up the pool wall past the waterline,

or “walk out of the pool”.

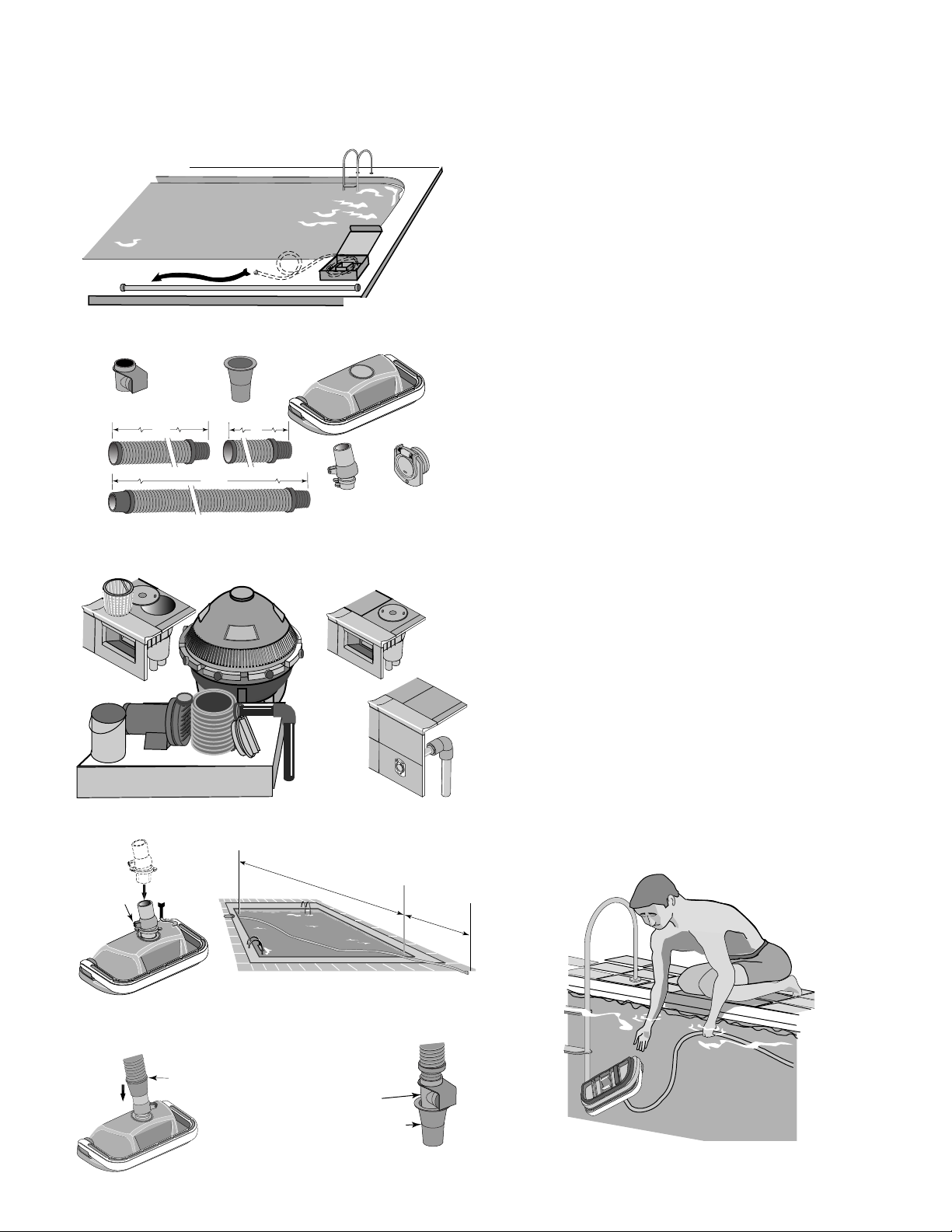

Movement around the pool

Random motion – The cleaner will visit most spots in

the pool in a 6 hour period. It is not specifically pro-

grammed and cannot see the dirt you are seeing. It is a

random motion cleaner.

The cleaner was designed to spend most of its time in

the deep end, where most of the floor and wall area

exists. During a 6 hour period the cleaner will visit the

shallow end a few times.

Rotating motion – The cleaner will rise up on one side

and pivot a few times per minute. This is normal and

provides the following:

1. Allows leaves that are being pushed or dragged along

to be sucked up into the vacuum chamber.

2. Allows the cleaner to:

Change direction

Get out of corners

Get away from ladders

Submerge below pool water level

Get off of domed main drain covers

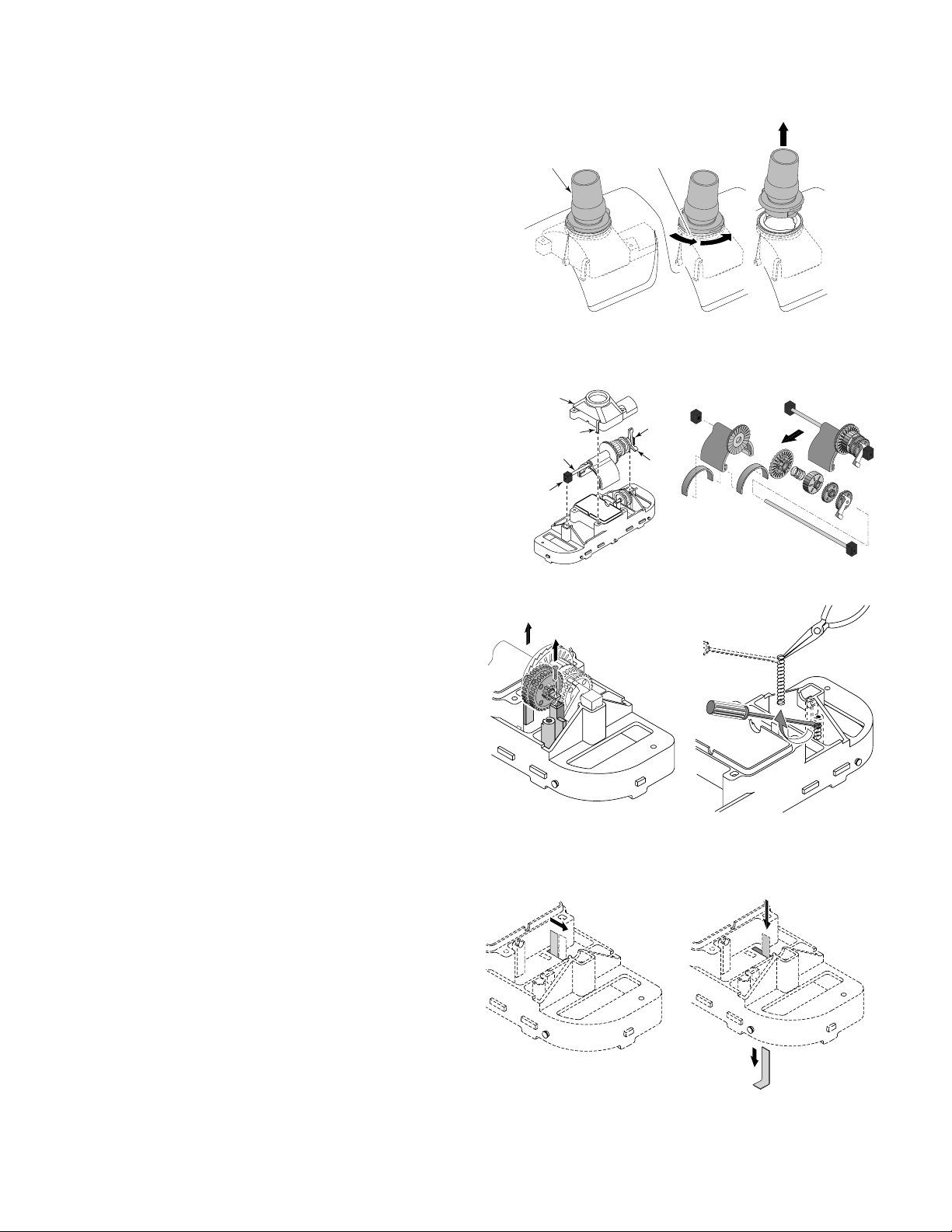

Picks up big “stuff”

The cleaner will pick up some debris so large that it

may jam. Simply stop the pump and remove the debris

from the oscillator or the swivel assembly.

ABOUT THE CLEANER OPERATION:

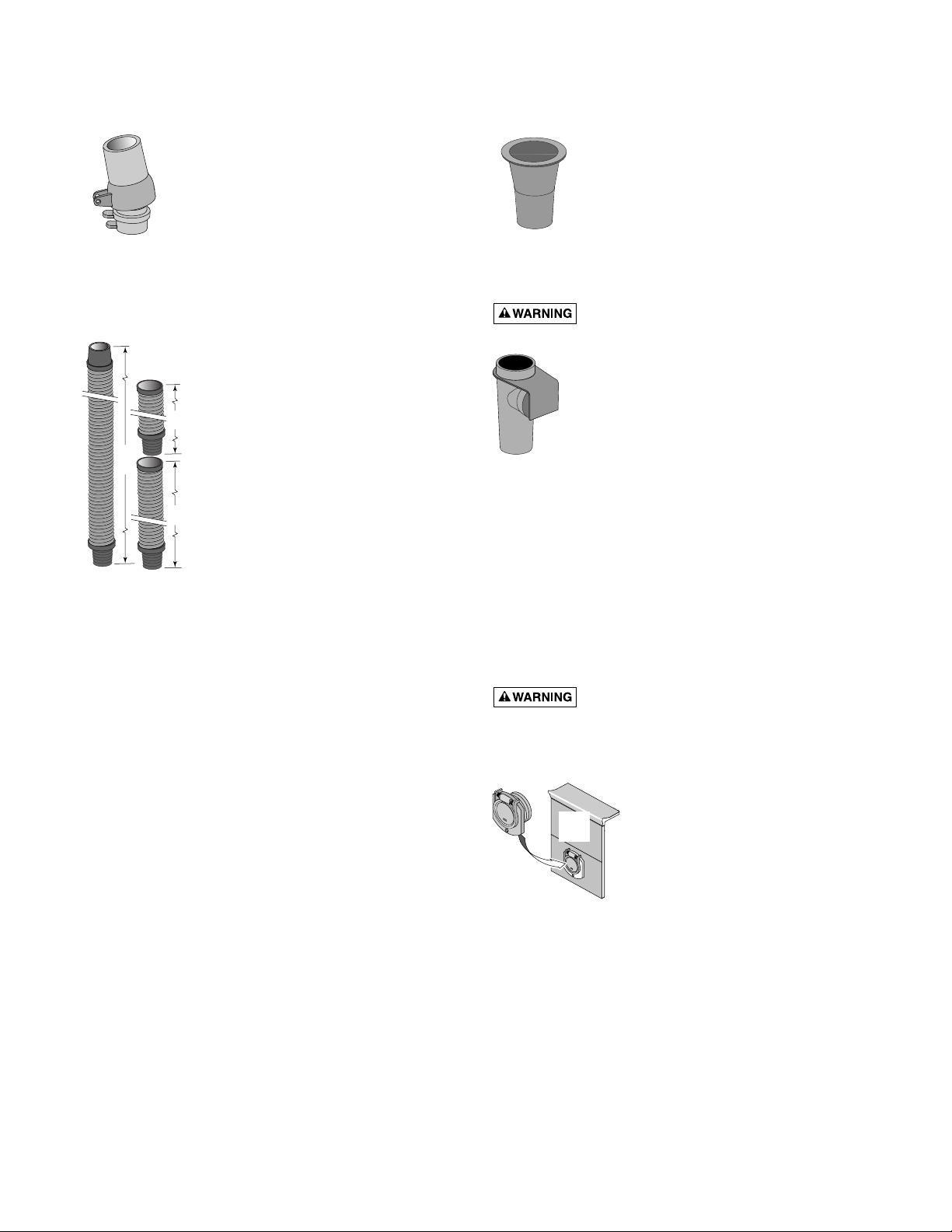

ABOUT “FINE-TUNING” VACUUM ADJUSTMENTS AND CONNECTIONS:

Pool pump suction is hazardous and

can cause entrapment with severe personal injury

or drowning. Use vacuum regulator (see instructions

below) in pool cleaner system at all times.

Note: Each pool’s hydraulic system and vacuum con-

nections are different. Be sure you have installed the

white plastic vacuum regulator before you “fine-tune”

the system. This not only regulates vacuum, but also

acts as a safety device.

Suction entrapment, injury, and drown-

ing hazard. If your pool has a dedicated suction

port (“vac port”) for vacuuming or for an automatic

pool cleaner, it must be covered when not in use. A

spring loaded safety cover (the “Vac Port Fitting”) is

included with this pool cleaner. Install it on the suction

port to prevent entrapment and injury. For details

please refer to the Vac Port instruction sheet included

with your Vac Port.

For the “NOVICE POOL OWNER” where vacuuming

is a new experience, please read all of the following

points, installation instructions, and trouble shooting

guide carefully.

Please note the following:

• “Vacuum” and “suction” are two words meaning the

same thing.

• “Dedicated suction line”, “vac port”, and

“vac fitting” are different terms for a

hole in the side wall of pool; this hole

is connected to the pump suction and

is dedicated to vacuuming.

•Some pools do not have a vac port. If

your pool does have one, please read

the “Suction Entrapment” warning at left.

For the “SEASONED POOL OWNER”: The automatic

pool cleaner connection and vacuum adjustments can

be similar to using your manual pool vacuum. Please

read on.

Valves (pump, skimmer, and main drain) and

vacuum adjustments

You may need to spend some time adjusting the skim-

mer and main drain valves in order to obtain the best

vacuum setting for good cleaner operation. Once you

have found the correct valve settings for best operation,

we suggest you mark the valves to ensure repeated

success.

At first, set valves to give maximum vacuum to the

skimmer or vac fitting you have elected to use.