Aquila TRIVENTEK BL25 MINI User guide

2

Aquila Triventek A/S · Industrivej 9· DK-5580 Nørre Aaby · Tel.+45 70 22 1292· aquila@triventek.com · www.aquila-triventek.com

Introduction............................................................................................................................3

Safety ....................................................................................................................................4

Safety data for Triblast-BL25 .................................................................................................6

Assembly of the equipment....................................................................................................8

Quality..................................................................................................................................10

Operating the equipment......................................................................................................11

Maintenance ........................................................................................................................14

Cleaning the equipment.......................................................................................................17

Storage ................................................................................................................................17

Recommended spare parts list ............................................................................................17

Troubleshooting...................................................................................................................18

Technical data......................................................................................................................20

Electrical chart for BL25.......................................................................................................21

Safety PartsIdentification.....................................................................................................22

EC Declaration ofConformity ...............................................................................................26

Warranty ..............................................................................................................................27

Delivery report......................................................................................................................28

DIB

-

D

RY

I

CE

B

LASTING

3

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Introduction

WearepleasedthatyouhavechosenthedryiceblastermodelBL25 MINIbyAquilaTriventekforyourcompany.

What can a dry ice blaster do?

•

The dry ice blaster particles accelerated to supersonic speed

•

Embrittles coating

•

Contaminate is ‘fraked’

•

Layer cracks and allows expanding gas to ‘push’ contaminateoff surface

Toobtainlongandtrouble-freeoperationoftheequipmentwerecommendreadingthismanualcarefully.Allnewopera-

torsoftheequipmentshouldalsofamiliarizethemselves with thecontentofthisdocument.

Wedorecommendmakingatrialspotontheobjecttobecleanedtobesuretheblastersettingsarecorrect,andthe

object is notdamaged.

What is DryIce?

Dryiceisfrozencarbondioxide(CO2).Theuniquepropertyofcarbondioxideisthatatatmosphericpressureitchanges

state from solid to gas without going through a liquid phase.

Thisprocessiscalledsublimation.Thispropertyisexploitedforcleaningsincethesolidphasepelletscanbeused

forblastcleaningandtheblastmediaeffectively‘disappears’ asgaswithoutanydamagingorawkwardliquidorsolid

residue.

Rapidsublimationofthedryicepelletasitcontactstheobjectbeingcleanedcausesamicro-explosionasthesolid

expandsinvolume800times,whichistheprimemeansofcausingcontaminatestoberemovedfromthesubstrate.

Thermal effects, differential coefficients of freezing and embrittlement, also contribute to the cleaning effect.

Awidevarietyofsubstratesandcontaminatescanbecleanedsuccessfullyandadvantageouslyusingdryice.Itis

recommended that any applications will be tested at first, to ensure the safety and effectiveness of the procedure.

Pellet size andquality

Formostcleaningpurposesstandard3mmcleaningpelletscanbeused.Theseare commonlyavailableonthemarket

but

can also be freshly produced using Triventek dry ice making equipment.

Micro-pellets down to 1.7 mm can be used for extremely delicate cleaning of e.g. fabrics and micro-electronics.

Cleaningquality,andthespeedofcleaning,isalwaysimprovedbyusingthefreshestpossibledryicepelletsofthe

highestquality(e.g.containingminimumwater/moistureorparticulates).Triventekoffersarangeofpelletizerandgas

recovery equipment to assist in ensuring the supplyof high quality, dry ice.

DIB

-

D

RY

I

CE

B

LASTING

4

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

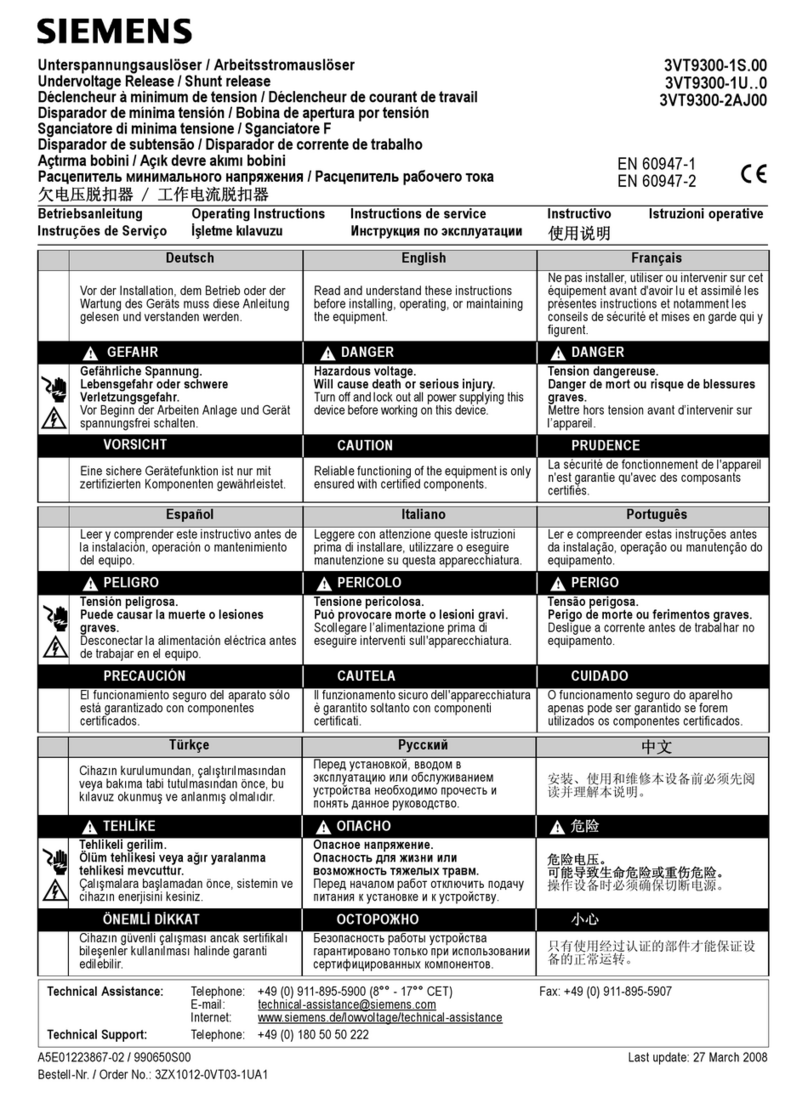

Safety

Safetydataforcarbondioxide(CO2)

Hazards identification

Solid

The blaster equipment uses solid dry ice pellets (also known as: frozen carbon dioxide and ‘Dry-ice’)

Contact with product may cause cold burns or frostbite due tothe low temperature at (minus)-79 C (-110F)

Above -79 C (- 110 F), solid dry ice sublimes into gas. This can cause pressure to build up in e.g. a container which is

not suitably vented.

First aid measures

If contact with eyes: Immediately flush eyes thoroughly with water for at least 15 minutes. In case of frostbite, spray

with tepid water for at least 15 minutes. Apply a sterile dressing. Obtain medical assistance.

Inhalation of sublimated CO2 (gas)

CO

2

isheavierthanairandmayaccumulatetohazardouslevelsinanunventilatedenclosedareasuchasatank,siloor

pit. Always ensure adequate natural or mechanical ventilation.

Use specific ventilation and/or breathing apparatus in any hazardous area such as a tank, silo or pit. CO2

isodorless

therefore it is recommended to use a CO2 detector in working areas.

Low concentrations of CO2 cause increased respiration and headache.

Inhighconcentrationscarbondioxidegascancauseasphyxiationbydisplacingtheoxygenrequiredforbreathing.

Symptomsmayincludelossofmobilityorconsciousness.Victimmaynotbeawareofasphyxiation.

First aid measures

Removevictimtouncontaminatedarea,therescuershouldwearbreathingapparatuse.g.anemergencybreathingair

bottleandmasktoensurethathe/shedoesnotalsofallvictim toasphyxiation.Keepvictimwarmandrested.Calla

doctor. Apply artificial respiration if breathing has stopped.

Exposure controls / personal protection

Exposurelimit: 5000 ppm

Personalprotection: Protecteyes,faceandskinfromcontactwithsolidproduct.Protectskin,especiallyhands,

from cold bywearing insulated gloves.

DIB

-

D

RY

I

CE

B

LASTING

5

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Transport information

Avoidtransportofcarbondioxideinsolid,liquidorgasphaseonvehicleswheretheloadspaceisnotseparatedfrom

the driver’s compartment.

Ensurevehicledriverisawareofthepotentialhazardsoftheloadandknowswhattodointheeventofanaccidentoran

emergency.

Before transporting product containers, ensure that they are firmly secured, and that adequate ventilation is provided.

Notethatafterblastcleaningwork,unuseddryicemayremainintheblaster,orintemporarystorageboxes.This

shouldbecarefullyallowedtosublimatebeforetransportationinacompartmentsharedwiththedriver.

Handling and storage of dry ice.

Use only properly specified equipment that is suitable for this product. Contact your supplier if in doubt. Refer to

suppli

er’s container handling instructions.

Keep container in a well-ventilated place.

Training

Thehazardofasphyxiationisoftenoverlookedandmustbestressedduringoperatortraining.Beforeusingthisproduct

inanynewprocessorexperiment,athoroughmaterialcompatibilityandsafetystudyshouldbecarriedout

Ensure all national / local regulations are observed. The European Industrial Gas Association (EIGA), see www.eiga.org/,

provides useful background material and guides to good practice.

DIB

-

D

RY

I

CE

B

LASTING

6

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Safety data for BL25 MINI

Before blasting, be sure to have the right safety precautions arranged i.e. carry out a risk assessment.

Besurethatonlypeoplewhoareproperlytrainedinhandlingtheblaster,andknowtherisksassociatedwithdryice,

are using theequipment.

Secure the area; be sure no unauthorized people will enter the working area.

Please confirm before blasting the nature of the coating or substance which is to be cleaned. In the

case of ha- arduous materials, appropriate safety precautions must be taken, such as Local

Exhaust Ventilation or Personal Protective Equipment.

Always use the following safety precautions:

Face protection or goggles

Wearprotectivegogglesorfaceprotectionwhenoperatingtheequipment,

toprotectagainst‘blowback’ ofthecontaminantbeingremo

ved.

Ear protection

Always wear adequate hearing protection

Highnoiselevelscanbeexperienced,dependingonthepressure,dryice

flow and shape of the object being cleaned. Ensure that nearby workers are

not exposed to excessivenoise.

Protective gloves

Alwaysusesuitablyinsulatedprotectivegloveswhenhandlingdryice,or

cold parts of themachinery.

Contact with product may cause cold burns or frostbite.

Breathing apparatus

Where insufficient ventilation, either naturally or by mechanical means,

can

-

notbeprovidedthenasuitablesupplyofbreathingairshouldbe

arranged.

Insuchcircumstances,itisalsorecommendedthatanemergency

bre

athingairbottleandmaskbeprovidedinthevicinityofanycarbon

dioxide

operations.

The emergency apparatus is for use by the rescuer in case of any

incapacitation of a person in an area where carbon dioxide has

accumulatedand

could cause asphyxiation to the rescuer.

DIB

-

D

RY

I

CE

B

LASTING

7

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Inhalation of vaporized CO2

Ininsufficiently ventilated spaces suchasa vessel, tankor small

roomanincreasedconcentrationofCO2mightleadtobreathing

difficulties and ultimately to suffocation.

Always ensure a supply of fresh air in enclosed rooms. A CO2

detec

tor should be used to confirm safe conditions. Where

necessary, use

a breathing mask with suitable fresh air supply.

Caution

Neverblastonpeopleorotherlivingcreatures.Compressedair

stream with pellets maycause severe injuries.

Never touch the pellet stream or the (cold) nozzle during operation!

Donotpermithorseplaywithdry ice.Ensurethatdry

icepellets

arenotingested,e.g.bybeingplacedindrinks.

Low temperature

Thedryicepellets’ temperatureis-79°C(-110°F)andthereforecan

cause severe freezeburns.

Donottouchorpermitdirectcontact withdry iceforanyextended

period. Use protective clothing and gloves.

Ensurethatpelletsdonotbecomelodgedunderneathclothingor

other protectiveequipment.

Note:partsoftheBlastermaybecomeextremelycoldduetocontact

withthe dry ice (e.g.the hopper, nozzle,air lock).

Earthing

BEWARE:

Pleaseconnecttheprovided7meters ofcablefromtheblasterto

the

objectbeingcleanedtoensureaproperearthinginorderto

avoida staticelectricaldischargecausedbythehighvelocityofthe

pellets/

air stream.

DIB

-

D

RY

I

CE

B

LASTING

8

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Assembly of the equipment

Transport

After the dry ice blasting unit has been delivered, it must be checked for damage which may have occurred during

transport. Ifnecessary, the transport company must beinformedtoregister thedamage within 24hours.Checkthat all

parts

described on the delivery note have been delivered.

Equipment

The BL25 by Aquila Triventek consists of the following items:

•

Dry ice blasterunit.

•

7 meters of blasting hose with built-in earthing cable.

•

Gun + 1 round nozzle 80/4 mm

•

Power supply cable 5 meter

Option:

•

Nozzle box with 5nozzles,2 straightextender pipes,1 curved pipeand3connectionpieces.

•

Dry ice crusher containing 3 sizes of net

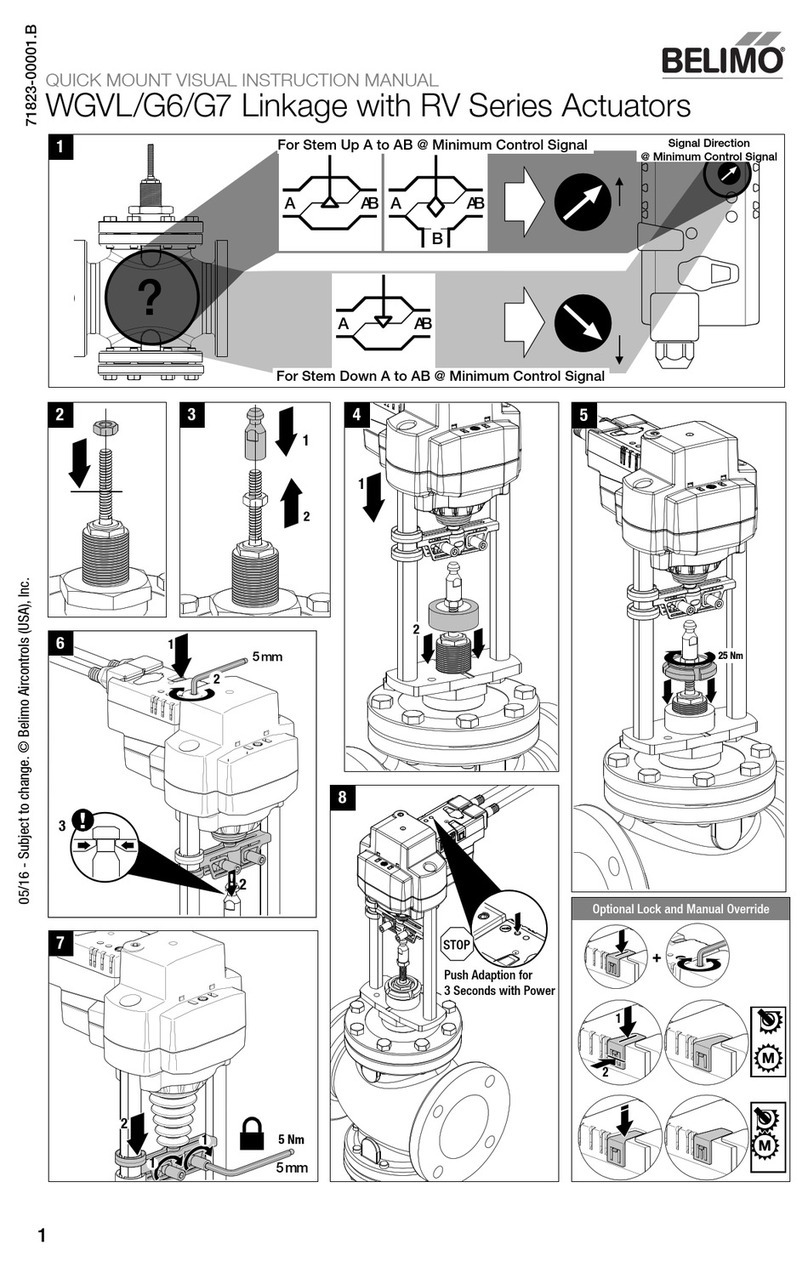

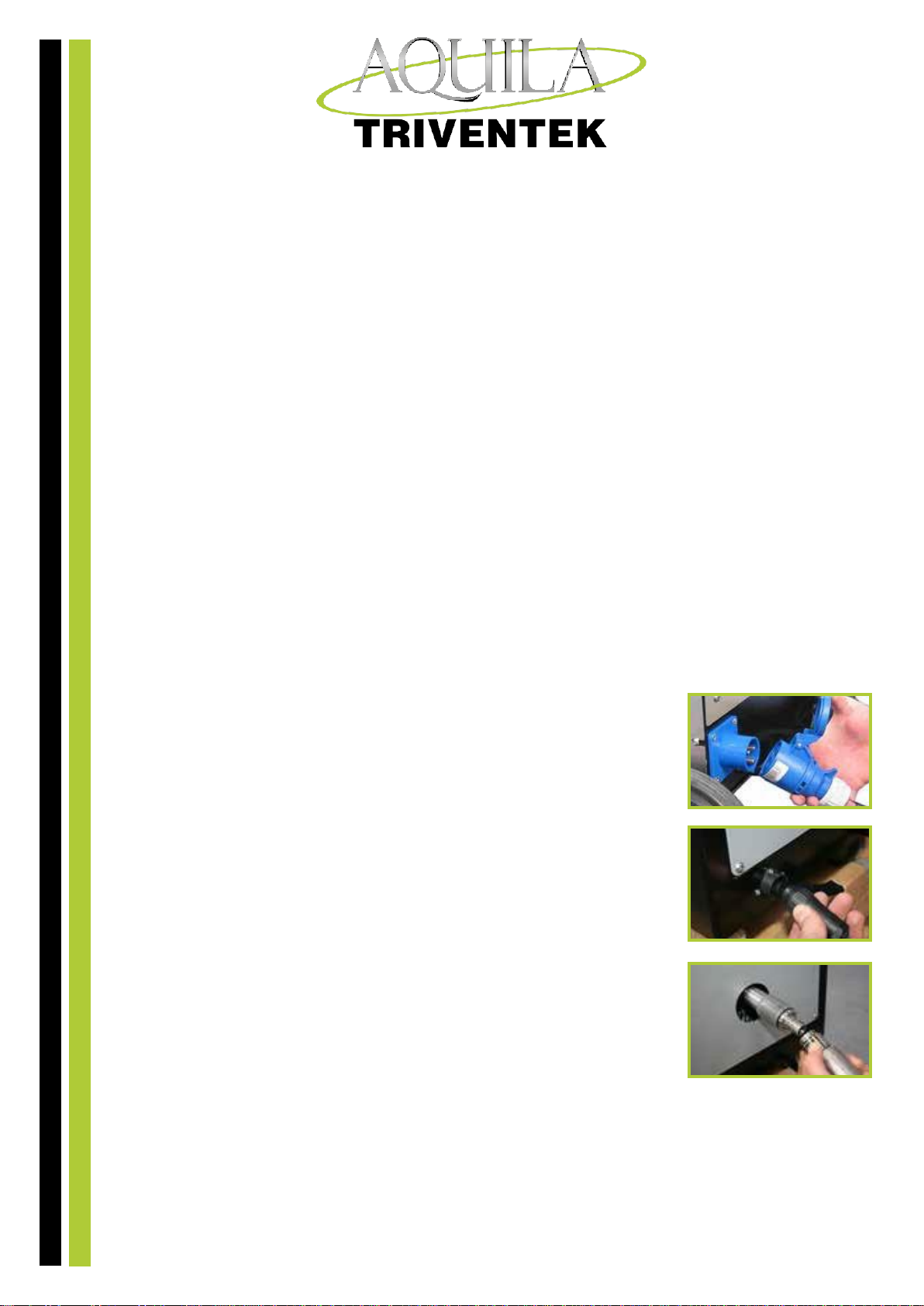

Connecting theequipment

Power:

Connect the power supply cable to an appropriate power supply.

(See reference to check power requirement on CE-sign on machine)

Cable and hose:

Connectthemalesocketofthecontrolcabletothesocket

atthefrontoftheblaster.Oncetheplugislinedup,twist

to secure.

Connecttheblastinghosetothehoseconnectionatthe

lowerfrontoftheblaster.Thisiseasilydonewiththe

snap-fit safety connection by pulling back the collar as

the hose is slid onto the machine.

DIB

-

D

RY

I

CE

B

LASTING

9

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Gun and Nozzles

Connect the gun to the control cable and the hose

Ifneeded,connecttheextensionpipe(s)tothegunby

screwingthepiecestogether(hand-tightonly)usingthe

connection piece(s).

Use a connection piece to connect the nozzle to the gun or

extension pipe (if fitted).

Use the twist-grip handle to ensure steady handling.

A variety of nozzles are provided for different cleaning applications.

Itisrecommendedthatatestarea/objectbeselectedtoestablishwhichtheappropriatenozzleforanycleaning

job.

DIB

-

D

RY

I

CE

B

LASTING

10

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Connecting tocompressor

Connectthecompressedairhosefromtheairsource(e.g.mobilecom-

pressoror fixed compressed air system) to the compressed air inlet on

the back of theblaster.

Ensurethatallhosesarecorrectlyconnectedandcheckthehosesfor

visible damage. Replace if damaged.

Neverdisconnecthoseswhenthesystemisrunningandpressurized.At

theendofablastingsession,firstshutdownthecompressedairsource

and then open the blasting gun trigger to depressurize the system.

Quality

Air quality

Alwaysusecleananddryair.Theairfromthecompressorshouldbedeliveredfreefromoil,particulateorhumidity.

It is recommended to use an after-cooler, water separator, fine oil and particulate filter and in some cases a refrigerant

dryer. If using factory air, from a fixed installation, ensure that consideration has been given to the heavy demand in

terms of volume that the blaster will make.

Pellet quality

Always use “fresh” dry ice pellets with a maximum diameter of 3mm.

Usingpelletscontaminatedwithmoisturecan resultinfreezingoftheairlockrotorplate andhosebyweticeand/orby

clogging.

Makesurethat

only

CO

2

pelletsareintroducedintothehopper.Anyforeignmaterialinthehopperwillleadtoserious

damage to theairlock.

Keepthehopperlidclosedasmuchaspossibletoavoiddirtfallingintothehopperandtominimizemoistureingress.

DIB

-

D

RY

I

CE

B

LASTING

11

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Operating the equipment

Blaster

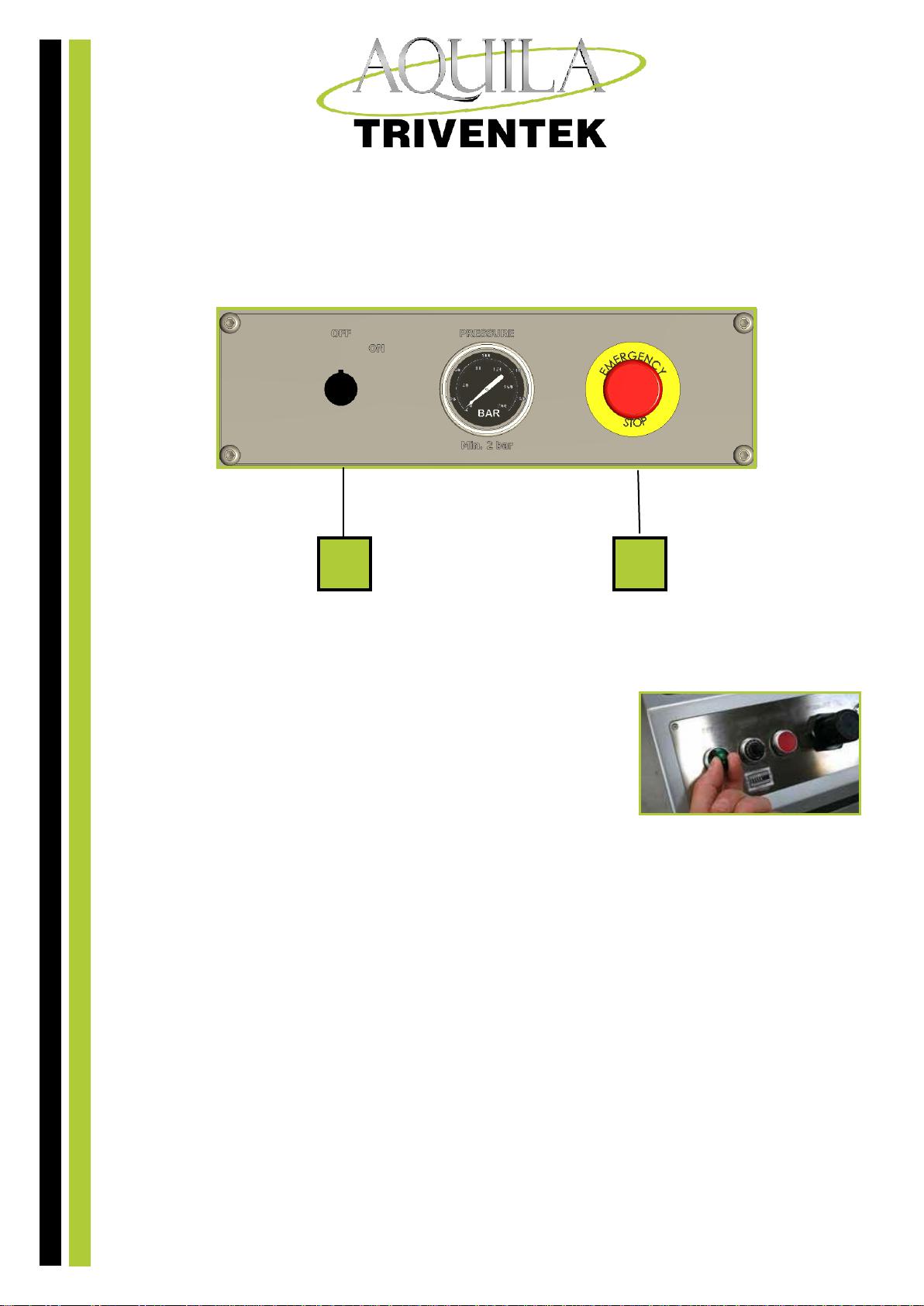

Top panel

1: Off/Ofn button

ToactivatetheBlaster,turntheOff/OnbuttontoOn.Thebuttonwill

lightgreen and theblaster is readyfor operation.

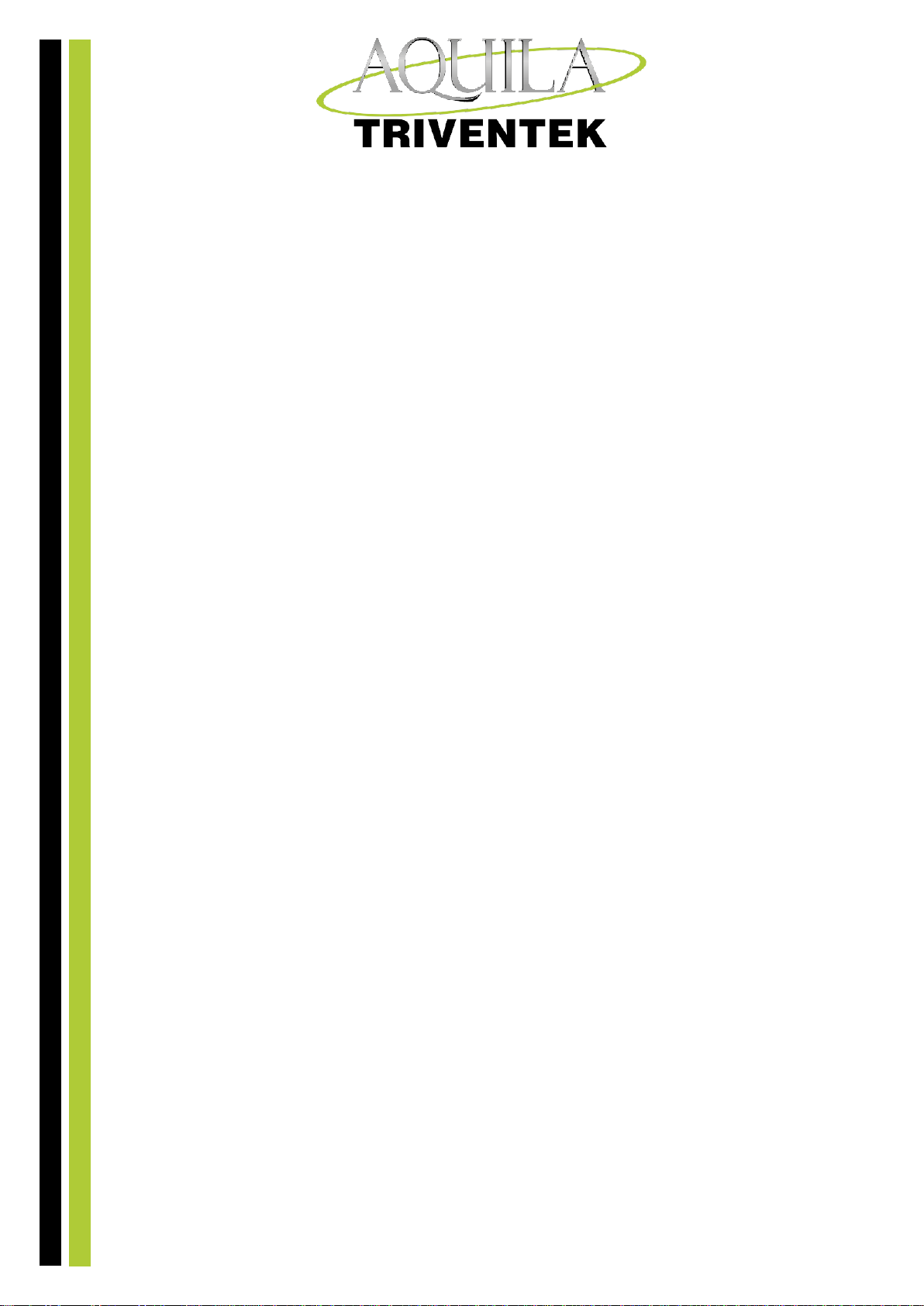

2: Emergency Stop

PushdownforEmergencyStopoftheblaster.WhenactivatedeverythingattheBlasterisstopped.Besurealsothatthe

operatorknows howtoisolateandshutdownthecompressedairsourceinan emergency.

By turning clockwise (right) the stop button is deactivated, and normal operation will resume.

2

1

DIB

-

D

RY

I

CE

B

LASTING

12

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Pressurizing

Openthevalveslowlyattheairsupply(e.g.compressor)totheBlastertoavoidheavypressureshocktothehoseand

Blaster. Such shock can damage the pneumatic components.

Feeding DryIce

NB: Before filling dry ice into the hopper ALWAYS activate the blast function for about 30 sec. by

pressing the button on the gun to empty the hose and machine of humidity or moisture.

Pourdryiceintothehopper.Usefreshdryiceforbestresultsandtoavoidclogging.Closethelidtominimizeevapora

tion

of dry ice and the ingress of humidity and dirt.

Use only dry ice. Other material will damage the equipment (and invalidate the guarantee)

Do not overfill the hopper. If the lid cannot be closed, then the hopper is overfilled.

Donotblastforanylengthoftime(afterinitialsystempurging)withoutdryice,sincetherotorwillrunextremelyhot

and may bedamaged.

DIB

-

D

RY

I

CE

B

LASTING

13

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Start/stop

Start of dry ice blasting

WhentheBlasterisconnectedproperly,correctairpressureisadjustedanddryiceisinthehopper,youarereadyfor

dry ice blasting.

Before starting blasting, have a firm grip of the gun and keep it away from other people. Stand in a safe working positi

on.

Tostarticeblastingpushthebuttonatthegunpistolgrip.

When starting, keep the gun some distance from object to

be cleaned until you are able to confirm the backpressure of

the gun.

Stop dry ice blasting

To stop, release the buttons at the gun.

Ifstoppingformorethanapproximately30minutes(dependingonroomhumidity),makesurethatthehopperisempty

andblastairthroughthesystemforashortperiodtoensurenodryiceisleftinthesystem.Thisavoidsdryice

clumping in the hopper and airlock chute

When the system is empty, stop blasting to avoid unnecessary wear of the rotating disc

Ifdryicepelletsarenotreturnedtostorage,careshouldbetakentoensuretheirsafedisposal.Avoidleavingpellets

exposedwhereuntrainedpersonsmaybeabletotouchthem,orwheresublimationcouldcauseahazardous

atmosphere.

DIB

-

D

RY

I

CE

B

LASTING

14

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Cleaning Objects

Attention!

•

Small objects should be fixed or mounted properly before blasting.

•

Do not leave loose parts in the blasting area.

•

Most contaminants tend to pulverize while cleaning. If the maximum total dust concentration of 6 mg/m³ (fine

dust)(orotherlocal/nationalcontrolvalues)isexceeded,a

mask

mustbeworn.Protectivemeasuresshould

be

takensuchasLocalExhaust Ventilationand/orother PersonalProtective Equipment.

A suitable mask or other control measures may be needed to protect against specific hazardous contaminants. In

poorlyventilatedenclosedspaces,forcedventilationorbreathingapparatusmaybeneededtoavoidasphyxiation

by sublimated carbondioxide.

•ThenozzleofthegundischargesgasesandCO

2

pelletsatveryhighvelocities(upto300m/secor1000ft/sec).

Never

aimthegunathuman beingsoranimalsorinthedirectionofotherworkersasserious/fatal injuriesmay

be

caused.

•

When activating blasting, back-thrust, in the opposite direction of the airflow, will occur. In order to anticipate the

reactivethrust,

always

takeawidestance (feetapprox. 60cm(2ft.)apartandyourupperbodyleaningintothe

direction where the nozzle points).

Maintenance

Activemaintenanceisnecessaryonlyiftheperformanceofthedryiceblastingmachineisnolongersatisfactory.

However,weadvise youtochecktheunit,atregularintervals, asdescribedhereunder.

Casing

Toaccesstheairlockformaintenance,unlockthecabinetlockwiththekey.Theblastercanbeopera

ted from therightside, left

side,andfront.Withoutthesidesandfront,youcanhavefull access to internal mechanics.

DIB

-

D

RY

I

CE

B

LASTING

15

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Maintenance Inspectioninterval

Check the airlock (pellet distributor system) for excessive air leakage

Every 100 operating hours or every 3 months, whichever comes

first.

Note:therewillalwaysbesmallamountsofair,andveryoccasionalpellet/

fragments/vapor,beingejectedoutofaslotatthesideoftheairlock.Thisis

donetorelieveanyexcesspressurewithintheairlockdryicepockets.

Spacer

If,duringblasting,excessiveairanddryicecomesoutbetweentheupper andloweraluminumpartsandtherotatingdisc,

thisisanindication that

therotating dischas worndown ortherotoris damaged.

Inthisevent,eithertherotatingdiscshouldbereplacedorthe4spacers(whichsetthedistancebetweentheupperand

loweraluminumplates)shouldbereplacedwith4smalleronestoensureanadequateseal.Sparesetsofspacersare

provided so that this operation can be carried out conveniently and cheaply.

Thespacersarebasically11mminlength.Theyaremarkedwithseveralnumbersofringstoindicatetheirlengthinterms

of

the‘n’ numberafterthedecimalplace.Thus,aspacerwith9ringsis10.9mmlong;aspacerwith8ringsis10.8mm

long.

Check the pneumatic system for air leakage bylistening. If there is any sound of unusual airflow, check the air hoses

visually for leakage.

Adjust theslow start airflowvalve(anti-thrustsetting)

The function of the slow-start air flow valve is to avoid a strong back-thrust

uponactivationoftheblaster.Whenpressingthebuttonsonthegunthevalve

will ensure that the air pressure builds up slowly.

Iftheair-valvedoesnotopenproperly,turnthecontrolpin:clockwise(right)

forslowerpressurebuild-up;anti-clockwise(left)forfasterpressurebuild-up.

Fixthechosensettingbytighteningthecheck-ringatthebaseofthecontrol

pin.

Sometimes the air valve will not open on starting blasting because of dirt,

moistureorexcessive main airpressure, making itdifficult to open the valve.Inthisevent, turnthe controlpin

an

ti-clockwise (left)toincreasetheopening pressure from thepneumatic control system.

DIB

-

D

RY

I

CE

B

LASTING

16

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

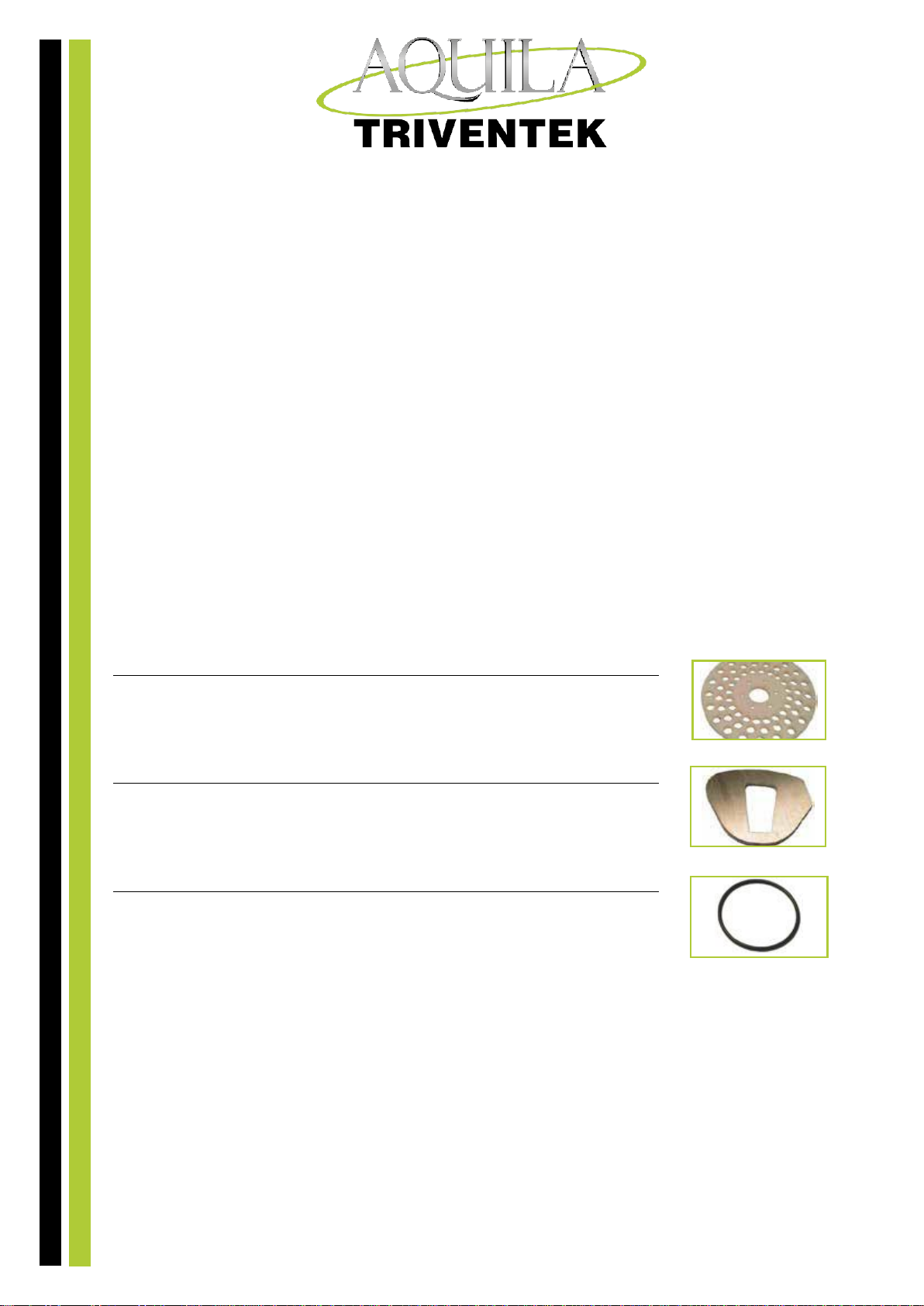

Dismantle theairlock

Undo the 2 bolts holding the inlet tube using an Allen (hexagon) key.

Undo the 4 bolts at the upper plate, using an Allen key.

Onturningovertheupperplate,removethefeedingslotpiece,whichis

loose.

Lift up, the plastic rotor disc

Remove the spacers.

Onreassemblyoftheairlock,takecaretoensurethatthefeedingslot

piece is held in position and that the O-ring is not damaged or

displa

ced.

DIB

-

D

RY

I

CE

B

LASTING

17

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Cleaning the equipment

Cleanwithlow-pressurecompressedair.Iftheequipmenthasbecomedirty,itshouldbecleanedbymeansofa

wiper moistened with a cleaning material (degreaser). Donot pressure wash.

Storage

The equipment can be stored in temperatures of - 5 C to + 40 C (23 F to 104 F). Please note, that temperature

chan

ges overnight of 20 C (68 F) might cause condensation (dew) inside the electronics, which can cause damage

to the

equipment.

Ifcondensationissuspected,thenplacethe equipment ina warmroom(15°C to22°C)(59°Fto72°F) for 1hour

before use.

Recommended spare parts list

Sparepartno.

Description

04102500

Rotor

04102511

Air Plate

33275206

O-ring

DIB

-

D

RY

I

CE

B

LASTING

18

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Troubleshooting

Itisveryimportantthattheequipmentshouldbemaintainedandoperatedasstipulatedinthismanual.

However,ifabreakdownshouldoccur,thefollowingschemecanbeusedfortroubleshooting.

Alwaysensurethatthesystemhasbeenappropriatelyshutdown,de-energizedandde-pressurizedbefore

attempting troubleshooting.

Problem

Possible cause

Solution

DIB

-

D

RY

I

CE

B

LASTING

Blaster does not start

Blaster stops

(Motor not running)

No power

Emergency button is pressed

The control button on gun must

be pressed for start-up

Unwantedparticlesorpartsin

airlock.

Overload of the electric motor.

Redlightilluminatedinthereset

button on toppanel.

Damage to control cable

Motor deactivated due to

overload.

Distance too narrow between

top and bottom plates in airlock,

causing the rotor plate to jam.

Checkifmachineisin” on” positionand

buttons is lighting up green

Turnemergencybutton(1/4)clockwise.

Press the control button at gun.

Dismantleairlock.Cleanandcheckfor

damage

Presstheredresetbuttonandthe

inverter/motorisresetautomatically.

Check inverter control for any error

message. A manual explaining the

inverteroperationanderrormessagesis

located,intheelectricalcontrolpanel.

Note that excessive voltage drops

(causede.g.byotherlargeequipment

startingupwhichdrawspowerfromthe

sameelectricalsupply)cancausethe

invertertostop.Ifso,findanother power

source.

Check the airlock.

Check for proper connection and

damage; possibly replace damaged parts

Loosen4boltsintopplatebyturning

bolts (1/4 turn at a time) and try

restarting.

Ifproblemcontinuesthenreplace

spacerswithlargerspacers.

19

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

InallothersituationswekindlyaskyoutocontacttheappointeddistributororAquilaTriventekA/Sforfurther

instructions.

Under no circumstances should an object (such as screwdrivers and similar objects) be put into the rotor plate

inlet below the feed chute. Otherwise you could damage the rotating disc. Such damage is not covered by the

manufacturer’s guarantee.

Problem

Possible cause

Solution

DIB

-

D

RY

I

CE

B

LASTING

No or little dry ice delivery

Lowairpressureatnozzle

when blasting

No pellets in the hopper

The blaster hose is twisted

Cloggingofdry-ice.Toomuch

moisture in airsupply

Hopper frozen

The hose, gun, pipe (or ice

crusher,ifused)and/ornozzleis

blocked byaniceplug

Problem with air supply and/or

compressor

Damaged rotor

Blasternozzletoobig

If used, ice crusher is blocked

Fill the hopper with pellets

Checktheblasterhoseanduncoilif

necessary.

Checkthatthecompressorhasawater

separator and after cooler.

Checkwhetherold,softor‘wet’ dryice

has‘bridged’ abovethefeeding blockat

the

bottom of thehopper

Remove clumpoficefromoutletof

hopper.

Makesurethathopperlidiskeptclosed

between fillings.

Checkforpelletblockageinsidethe

blaster hose

Ifso,disconnecttheblasterhoseand

gunandletthedryicesublimate.

Sublimationcanbemadefasterby

applyingheat(takingcaretoavoid

damagetoe.g.thesiliconhose)

Ificecrusherblocks,ensurethatalarge

aperturenozzle(e.g.100/15)isbeing

used;tryhigherpressure,orolder,softer

dry ice, or larger size grating

Checkairpressureatthemanometeron

thecompressor/airsupply.Checkair

supply hoses.

Check the airlock

Change to a smaller nozzle

See above re ice crusher

20

Aquila Triventek A/S · Industrivej 9 ·DK-5580 Nørre Aaby · Tel.+45 70 22 1292 · aquila@triventek.com · www.aquila-triventek.com

Technical data

Dimensions

L:560mm W:550mm H:720/985 mm

Weight

49kg

Hopper

6Kg

Air pressure

Min: 2bar Max: 10bar

Power supply

DIB

-

D

RY

I

CE

B

LASTING

110 V-230 V

AC 50-60 Hz

Air flow range

Dry ice consumption

Noise

0,6-3 m3/min

40 Kg/h

86-120dB (at 6 bar pressure)

Table of contents