In addition to this operators manual, a packet containing IMPORTANT INFORMATION has been

enclosed with your CIMLINE M-Series Melter.

The following Manufacturer's Documents are included for the following parts:

a) Engine

b) Material Pump

c) Burner

TABLE OF CONTENTS:

Serial Number, Model Number, Engine Number .....................................3

Contacting Cimline ..............................................................................3

Personal Safety, Signal Words in Manual ..............................................4

Trailer Safety......................................................................................5

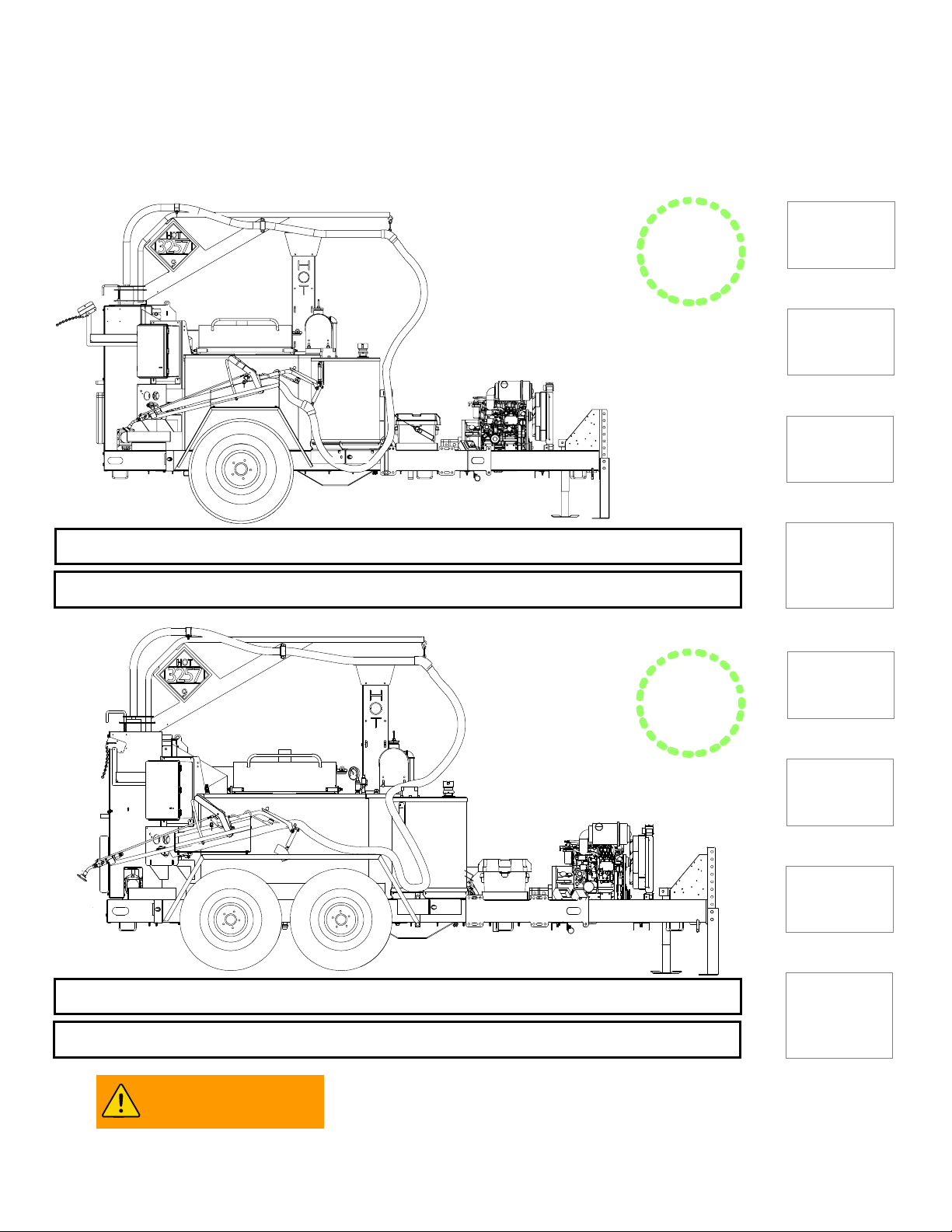

M-Series Weight and Dimensions .........................................................6-7

Replacement Labels ............................................................................8

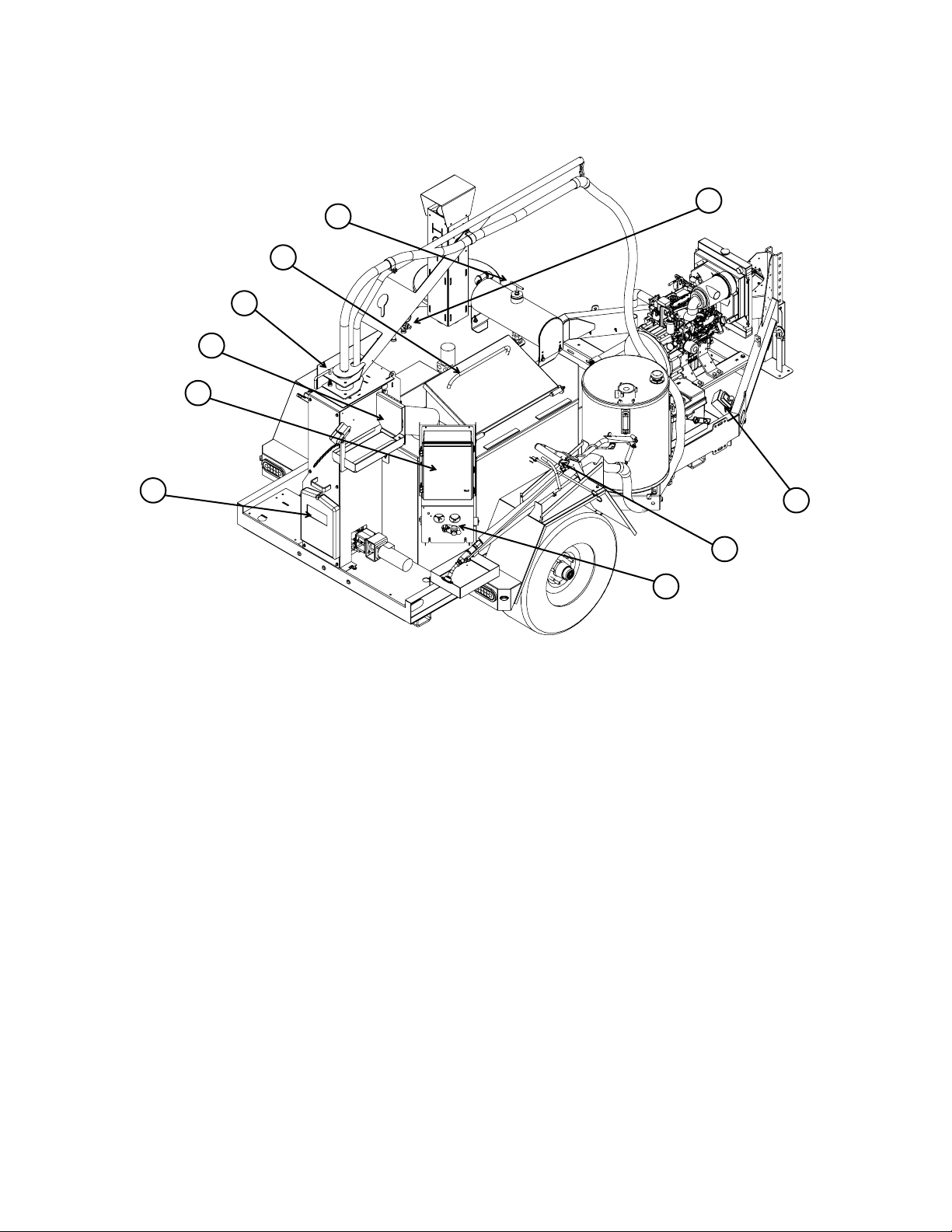

M-Series Feature Overview..................................................................9

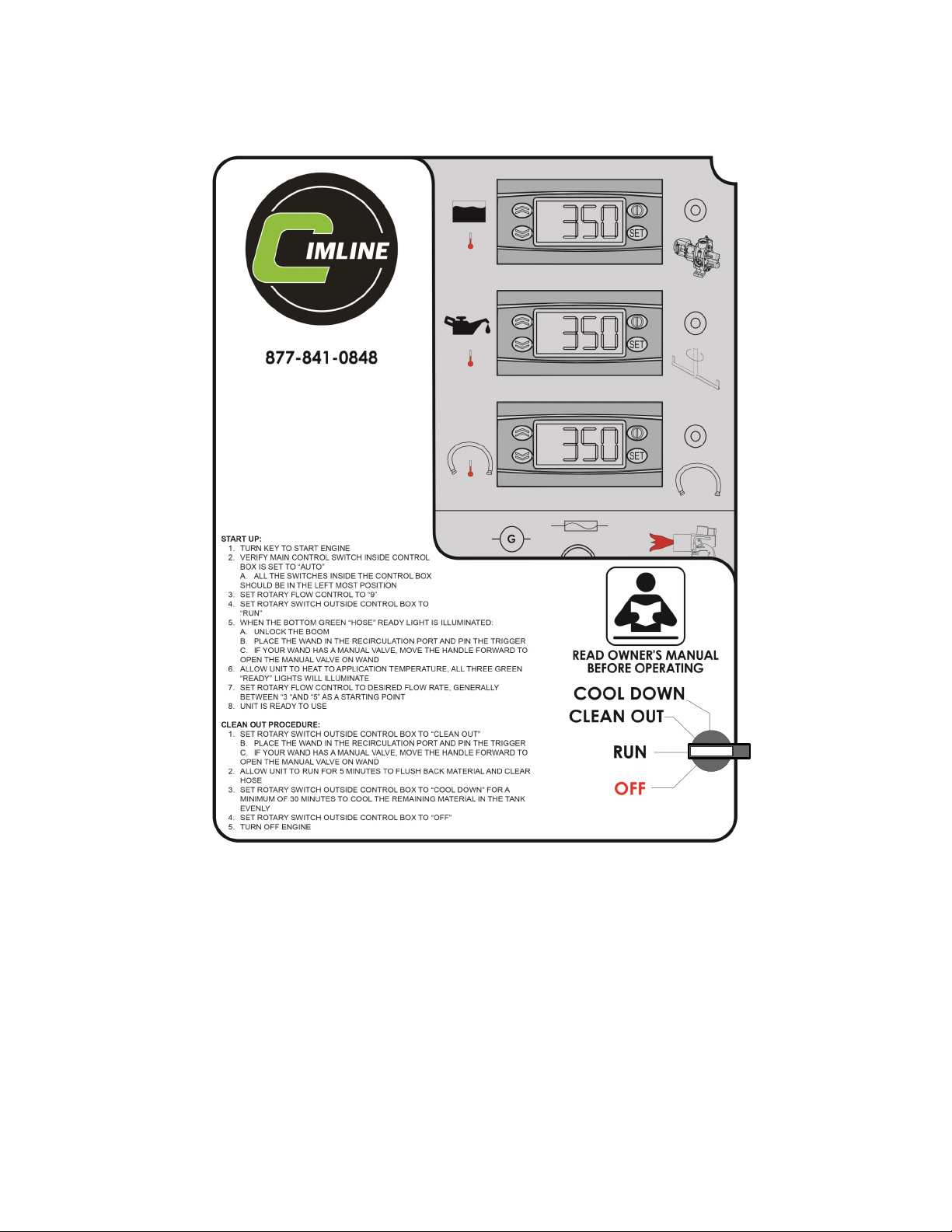

M-Series Control Panels and Their Functions ........................................10-11

M-Series Manual Sub Control Panel and its Functions ...........................12-13

M-Series Start Up Procedure ...............................................................14-15

M-Series Clean Out/Shut Down Procedure ............................................16-17

M-Series Sealant Material Tank Capacity ..............................................18

M-Series Automatic Temperature Control Setting ..................................19

M-Series Fluid and Components Specifications .....................................20

M-Series Heat Transfer Oil Specs ........................................................21

MAINTENANCE AND TROUBLESHOOTING:

M-Series Maintenance Schedule.............................................................................23

M-Series Maintenance - Changing Heat Transfer Oil..............................................24

M-Series Maintenance - Sealant Material Pump .....................................................25

M-Series Maintenance - Sealant Material Plumbing................................................26

M-Series Maintenance - Recirculation Valve Timing ...............................................27

M-Series Maintenance - Hydraulic Oil Servicing .....................................................28-29

M-Series Maintenance - Tank Burner......................................................................30-34

M-Series Maintenance - Trouble Shooting Guide....................................................35

M-Series Melter Applicator Service Parts Kits ........................................36-37

PARTS AND ASSEMBLY DIAGRAMS:

M-Series Trailer Wiring Diagram and Parts ...........................................39

M-Series Main Wiring Harness .............................................................40-41

M-Series Control Panel Wiring Diagram and Parts .................................42-45

M-Series Combustion Chamber Parts ...................................................46

M-Series Tank Burner Internal Wiring Diagram ......................................47

M-Series Tank Burner Parts .................................................................48

M-Series Hydraulic Reservoir and Diesel Tank Parts .............................49

M-Series Hydraulic Manifold Parts and Schematic .................................50-53

M-Series Diesel Engine Components ....................................................54-57

M-Series Sealant Material Plumbing Parts ............................................58-63

M-Series Sealant Wand Diagram and Parts ...........................................64-66

M-Series Agitation System Diagram and Parts ......................................67-68

M-Series Miscellaneous Components and Parts ....................................69-71

M-Series Optional Sealant Wand Attachments.......................................72

Shipping Papers and Information