3

CONTINUES

• Manualforewordanduse ................................................................................................................................................. 5

• Manualusemodes ............................................................................................................................................................ 5

• Limitations ......................................................................................................................................................................... 5

• Responsibility.................................................................................................................................................................... 5

1 Risksandprotectionsbeforeassembly.......................................................................................................................... 6

2 BravoDSB.......................................................................................................................................................................... 6

3 Intendeduse ...................................................................................................................................................................... 6

4 Precautions ........................................................................................................................................................................ 6

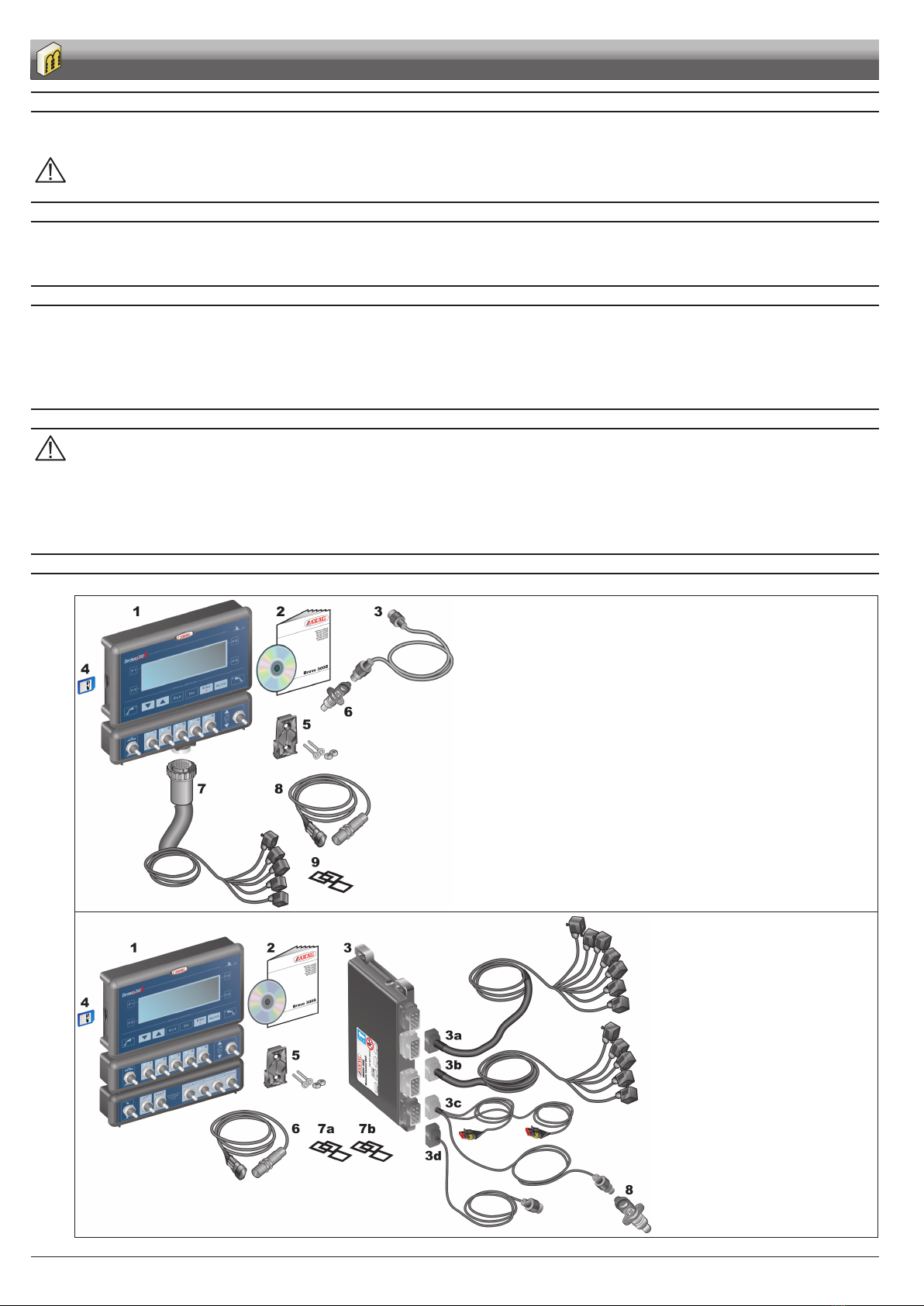

5 Packagecontent ................................................................................................................................................................ 6

6 Positiononfarmingmachine ........................................................................................................................................... 7

6.1 System recommended composition ........................................................................................................................... 7

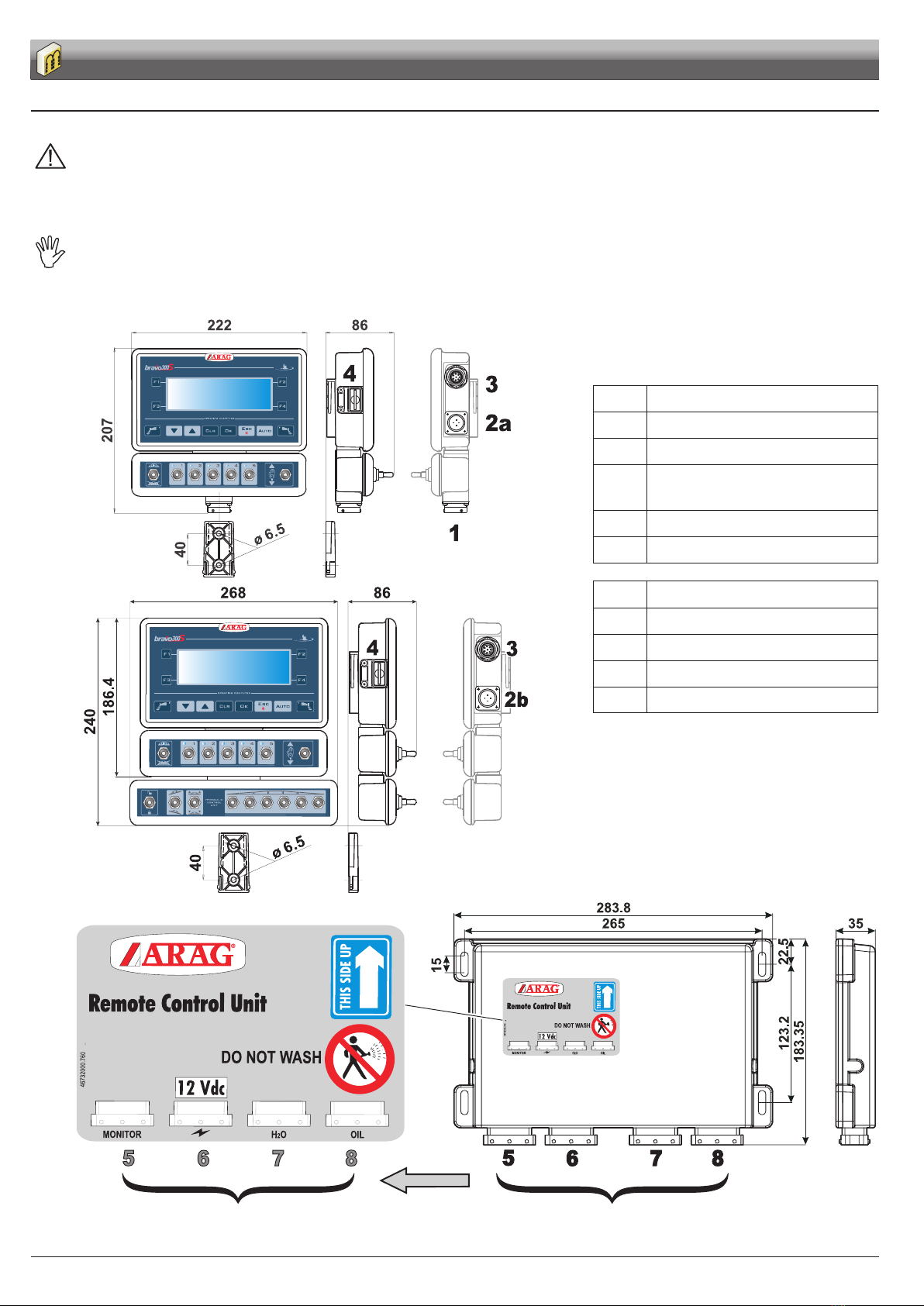

6.2 Monitor and control unit positioning...........................................................................................................................10

6.3 Bracket fixing.............................................................................................................................................................11

6.4 Control unit (RCU) fixing ...........................................................................................................................................11

6.5 Control unit position...................................................................................................................................................11

7 Computerconnectiontothefarmingmachine............................................................................................................. 12

7.1 General precautions for a correct harness position.................................................................................................. 12

7.2 Power supply connection.......................................................................................................................................... 13

8 Harnessconnectiontothecontrolunit,thehydraulicunitandtheavailablefunctions .......................................... 14

8.1 Multicore connector connection (FOR VERSIONS WITH DIRECT CONNECTION ONLY) ..................................... 14

8.2 Remote control unit (RCU) connection..................................................................................................................... 14

8.3 Control unit valve connection ................................................................................................................................... 14

8.4 Hydraulic valves connection ..................................................................................................................................... 15

8.5 Connection of sensors and other available functions .............................................................................................. 16

8.6 SD memory card ...................................................................................................................................................... 17

9 Setup................................................................................................................................................................................. 18

9.1 Tests and checks before programming..................................................................................................................... 18

9.2 Computer switching On/Off ...................................................................................................................................... 18

9.3 Use of keys for programming.................................................................................................................................... 19

10Advancedsetup............................................................................................................................................................... 20

10.1 Language ................................................................................................................................................................. 21

10.2 Unit of measurement................................................................................................................................................ 21

10.3 Section valves number ............................................................................................................................................. 21

10.4 Coverage.................................................................................................................................................................. 21

10.8 Valves....................................................................................................................................................................... 22

10.5 Flowmeter................................................................................................................................................................. 23

10.6 Pressure sensor ....................................................................................................................................................... 23

10.7 Delivery cal. sensor .................................................................................................................................................. 23

10.9 Tank level ................................................................................................................................................................. 24

10.9.1 Tank level - Manual Mode ...................................................................................................................................... 24

10.9.2 Tank level - Filling flowmeter mode ........................................................................................................................ 24

10.9.3 Tank level - Level sensor mode .............................................................................................................................. 25

10.10 Rev counter ............................................................................................................................................................. 26

10.11 Foam marker ........................................................................................................................................................... 26

10.12 Pump Protector........................................................................................................................................................ 26

10.13 Configuration check after Advanced setup end ....................................................................................................... 27

CONTENTS