3

CONTENTS

CONTINUES > > >

1 Risks and protections before assembly.................................5

2 Intended use .............................................................................5

3 Precautions ...............................................................................5

4 Package content .......................................................................6

5 Position on farming machine ..................................................7

5.1 System recommended composition.................................7

5.2 Computer positioning.......................................................8

5.3 Bracket fixing ...................................................................9

5.4 Control unit position .........................................................9

5.5 Hydraulic unit positioning.................................................9

6 Wiring connections ................................................................10

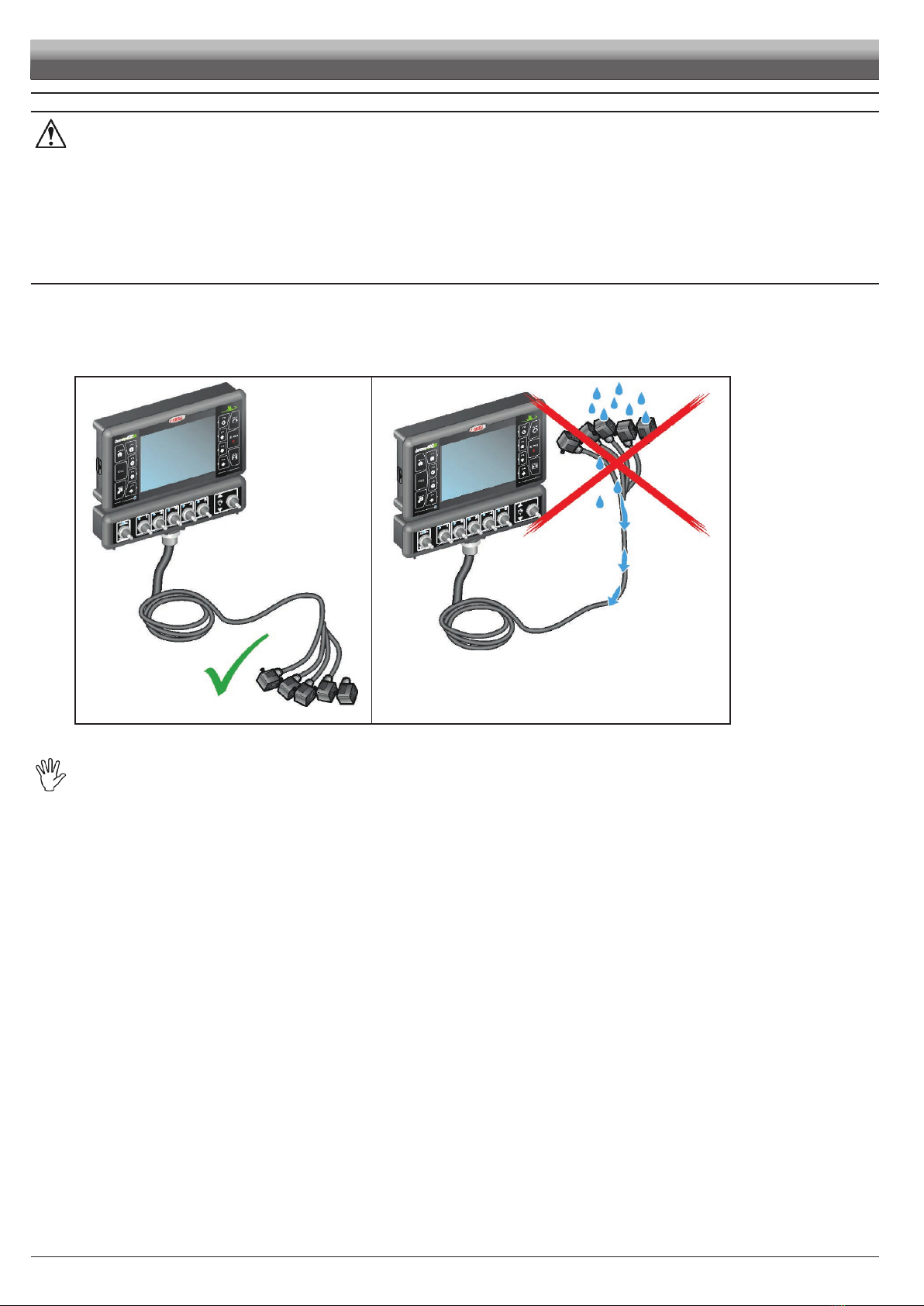

6.1 General precautions for a correct harness position .......10

6.2 Control unit valve connection.........................................11

6.3 Hydraulic valve connection ............................................11

6.4 Sensor connection.........................................................12

6.5 Auxiliary functions..........................................................12

6.6 Power supply connection ...............................................13

7 Accessories ............................................................................14

7.1 SD memory card............................................................14

7.2 Pendrive.........................................................................14

8 Setup........................................................................................15

8.1 Setup preparation ..........................................................15

8.2 Switching on ..................................................................15

8.3 Switching off...................................................................16

8.4 Use of keys for setup .....................................................17

9 Menu structure........................................................................18

10 Basic settings .........................................................................19

11 Advanced setup ......................................................................20

11.1 Configuration management............................................20

11.2 Device reduced configuration ........................................21

11.3 Settings..........................................................................22

11.4 IMPLEMENT SETTINGS...............................................23

11.4.1 Boom settings..................................................................... 23

• Number of covered rows ................................................ 23

• Number of nozzles per half-row ..................................... 23

• Total number of nozzles .................................................. 23

• Half-rows coverage ......................................................... 23

• Half-rows enablement ..................................................... 25

11.4.2 Flowmeter........................................................................... 25

• Type ................................................................................. 25

• Constant: ......................................................................... 25

• Minimum flowrate ............................................................ 25

• Maximum flowrate ........................................................... 25

11.4.3 Filling flowmeter.................................................................. 26

• Type ................................................................................. 26

• Constant: ......................................................................... 26

• Minimum flowrate ............................................................ 26

• Maximum flowrate ........................................................... 26

11.4.4 Pressure sensor.................................................................. 27

• Activation status .............................................................. 27

• Type ................................................................................. 27

• Maximum pressure ......................................................... 27

11.4.5 Valves ................................................................................. 27

MAIN VALVE........................................................................ 27

• Type (REMINDER) .......................................................... 27

• Automatic closing of section valves ................................ 27

• Automatic closing of main valve ..................................... 27

• Switching time ................................................................ 27

PRESSURE REGULATING VALVE...................................... 28

• Regulation direction ........................................................ 28

• Type ................................................................................. 28

• Aggressiveness .............................................................. 28

SECTION VALVES............................................................... 28

• Type ................................................................................. 28

• Shut-off time .................................................................... 28

• Switch-on time ................................................................ 28

11.4.6 Nozzles data....................................................................... 29

• Flowrate .......................................................................... 29

• Pressure .......................................................................... 29

• Minimum pressure .......................................................... 29

• Maximum pressure ......................................................... 29

11.4.7 Wheel sensor ...................................................................... 29

• Constant: ......................................................................... 29

11.4.8 Rev counter ........................................................................ 30

• Status .............................................................................. 30

• Constant: ......................................................................... 30

• Minimum rotation speed ................................................. 30

• Maximum rotation speed ................................................ 30

11.4.9 Tank .................................................................................... 30

• Reserve level .................................................................. 30

• Capacity ......................................................................... 30

• Reserve level .................................................................. 30

• Tank profile ...................................................................... 30

11.4.10 Alarms................................................................................. 31

NOZZLE ALARMS.............................................................. 31

• Nozzle wear check ......................................................... 31

• Nozzle wear limit percentage ......................................... 31

• Minimum pressure alarm ................................................ 31

• Maximum pressure alarm ............................................... 31

FLOWMETER ALARMS...................................................... 31

• Minimum flowrate alarm .................................................. 31

• Maximum flowrate alarm ................................................. 31

REV COUNTER ALARMS .................................................. 31

• Minimum rotation speed alarm ....................................... 31

• Maximum rotation speed alarm ...................................... 31

11.4.11 Working parameters............................................................ 32

SPRAYING LIMITS ............................................................. 32

• Spraying speed limit ....................................................... 32

• Minimum spraying speed ............................................... 32

• Regulation pressure limit ................................................ 32

• Minimum regulation pressure ......................................... 32

• Flowrate correction factor ............................................... 32

• Tank level correction factor .............................................. 32

AUTOMATIC SECTION CONTROL..................................... 33

• Sections overlapping limit .............................................. 33

• Perimeter overlapping limit ............................................. 33

• Spray closing delay ........................................................ 34

• Spray opening advance ................................................. 34

GUIDANCE ......................................................................... 35

• Steering radius ............................................................... 35

• Reference line distance compensation .......................... 35

11.4.12 Device calibration............................................................... 36

SENSORS .......................................................................... 36

• Pressure sensor zero value ............................................. 36

• Tank level zero value ....................................................... 36

• Tank profile calibration .................................................... 36

11.5 IMPLEMENT GEOMETRY

(MACHINE WITH TOWED / CARRIED IMPLEMENT) ...38

11.5.1 Geometry settings (TOWED IMPLEMENT)......................... 38

11.5.2 Geometry settings (CARRIED IMPLEMENT) ..................... 39

11.6 GPS RECEIVER SETTINGS.........................................40

11.6.1 Tilt compensation ............................................................... 40

11.6.2 Correction type ................................................................... 40

11.6.3 HDOP alarm ....................................................................... 41

11.6.4 Receiver advanced data .................................................... 41

11.6.5 Receiver update - for Smart range receivers ONLY ........... 41

11.6.6 Minimum quality - for NMEA / A100 receivers ONLY .......... 41

11.6.7 Baud rate - for NMEA receiver ONLY ................................. 41