ARBE MD-205 User manual

Thank You &Congratulations

On Your Purchase of:

ARBE

Model # MD-205

Table Top Dust Collector

" The Most Powerful Dust Collector In Its

Class... Guaranteed "

. t.....,

I ,

I

AI R IBIC

I

54 AileDBlvd'.• fa~DlIO.dale. NY

11135

I, ,

WEB;www.arbemacblno.com

, ,'.~ilIME"fG.,INC.

Tel

11

631.156.2411

Fax ~ ,631.156.2485

E~all:

Int8@&rllftmacbloB.nm ,

- • I

"

I, '. -

IMPORTANT INSTRUCTIONS' ·

DO NOT DISCARD

Thank you once again for purchasing an ARBE Machine product. Arbe

Machine Mfg., Inc. takes pride in manufacturing the highest quality jewelry

casting and polishing equipment in the industry. Your product has been

thoroughly tested and inspected prior to being shipped. Should any damage

have occurred in transit, please contact the freight forwarder immediately.

The receiver of a product must file a claim with the carrier within 14 days of

receipt. If any assistance is required in processing the claim, do not hesitate

to contact Arbe Machine at (631) 756-2477.

INSTRUCTIONS:

Remove the dust collector from its packaging and place on a sturdy and level

surface.

Operation of this or any other type of equipment should be done by trained

personnel.

Plug the unit's cordsets into grounded electrical receptacles. Never remove

or alter original plugs supplied with the unit's power cord. The dust

collector can be easily turned on by the power switch located on the front

right-hand side of the unit.

Operator safety may require suitable safety devices or procedures as

specified in National Safety Codes. When installing buffing wheels for first

time, Arbe Machine recommends that the operator stand aside for atleast one

minute. Debris in the wheel may be thrown out during the first moments of

the machine's operation,

OPERA TION PRINCIPLE:

The air is drawn into the unit through the air intake holes located on the front

panel of the machine, The contaminated air passes through the fiberglass

filter. The clean air is then released through the exhaust holes on the back of

the machine. Arbe Machine recommends a minimum of afour-inch

clearance between the back exhaust side of the machine and any wall or

partition.

EQUIPMENT MAINTENANCE PROCEDURES:

The unit is equipped with a double-shielded permanently lubricated ball

bearing motor, assuring long lif and

quiet

operation. No additional motor

maintenance is required.

The polishing spindles equipped with the unit are

Y2

tapered spindles.

Proper maintenance is critical to extend the life and efficiency of the

filtration system. The information presented below outlines basic

maintenance procedures to ensure the ARBE Model #MD-205 unit will

provide a trouble free and clean work environment for years to come.

GENERAL FILTER MAINTENANCE:

Polishing dust

is

accumulated onto the surface of the fiberglass filter located

inside the dust collector. Fiberglass filter can be easily changed by removing

the top cover of the unit.

It

is very difficult to pre-determine a specific maintenance schedule, as the

rate of dust loading will vary for each person. To ensure maximum suction

throughout life of unit, Arbe Machine recommends the fiberglass filter be

changed once a month. Only Arbe Machine filters should be used when

changing filters to ensure safety and efficiency of unit.

Arbe re-order Model #MD-205.002 (Fiberglass Filter

FI

#MD-205)

*NOTE: When opening top access cover to remove fiberglass filter, unit

must be powered off.

Safety Precautions:

Keep all fastening hardware, including spindles, tight to ensure that the unit

is in a safe working condition.

Unplug unit from electrical outlet when any servicing is being done.

Never operate unit without access doors securely in place.

Keep all loose clothing, hair or dangling objects from shafts or buffing

wheels.

I. GROUNDING INSTRUCTIONS

This tool should be grounded while in use to protect the operator from electric shock. The

1001

is equipped

with an approved three-conductor cord and three-prong grounding type plug to

fit

the proper grounding type

receptacle. The green (or green and yellow) conductorin tile cord is tile grounding wire, Never connect the

green (or green and yellow) wire to a live terminal. Hyour unit is for use on less 1I1an150 volts, it has a plug

that looks like that shown in sketch (A) in Figure 1. If

it

is for use on 150 to 250 volts,

it

has a plug that looks

like that

shown

in sketch (B).

Use of

an

extension cords

or a 2 prong adapter is

n01

recommended

FIGURE 1

GROUNDING METHODS

.GJ.',. '::

:

:-

:' J::

::E:j' "';

'~:'--::

~

::

i~:··.~~

COVER Of GROUNDED

(A) OUTLET 80X (13)

II. TOOL SAFETY INSTRUCTIONS

1. Keep Work Area Clean

Cluttered areas and benches invite accidents.

2_

Avoid Dangerous Equipment

Don't expose power tools to rain. Don't use power

tools in damp or wet locations. Keep work area

well

lit.

3.

Keep Children Away

AI visitors should be kept sale distance from work

area and appliance.

4. Store Idle Tools

When not in use, tools should be stored in dry,

high. and locked location out

01

the reach ot

children.

5. Don't Force

Tool

It will do the job beller and be safe at the rate for

which it was designed.

6.

Use

Right Tool

Don't force small too or attachment to do the job of

a heavy-duty tool.

7.

Wear Proper

Apparel

Do not wear loose clothing or jewelry which may

get caught in moving parts. Tie back long hair or

use a proper hair

net

i , "-

Sr';---.'--'".',

-riTL

a.

Use Safety Glasses

Use safety glasses with all rotating tools. Also use

a face

or

dust

mask

if

cutting operation

is

dusty.

9. Don't Abuse Cord

Never carry tool by cord or yank it to disconnect

from receptacle, Keep cord from heat, oil, and

sharp edges.

10.

Secure Work

Use clamps or a vise to hold work. It's safer than

using your hand and it frees both hands to operate

tool.

11.

Don't

Overreach

Keep proper footing and balance at all times.

12. Maintain

Tools

with Care

Keep tools sharp and clean lor best and safest

performance. Follow instructions lor lubricating

and changing accessories,

13.

Disconnect Tools

When not in use: before servicing; when changing

accessories such as blades, bits, cutters, etc.

__ ~¥

A --..,._:--; __ ._. _,_ ••

-r_. ~.-..-_--- .-,. •__ ...

14. Avoid

Accidental

Starting

Be sure switch is OFF when plugging in.

, ,>I HUUB

AMERICA

MANUIACTUBll

,,,,"

WARRANTY POLICY

Arbe Machine Mfg., Inc. warrants all products furnished

by

it

are free

from defects in material and workmanship at the time of shipment

for

a period of

eighteen (18) months from the date of shipment, or one (1) year from the date of

installation, whichever occurs first.

Claims

must be made

during

that period and

are limited to the replacement of parts claimed to be defective.

This warranty shall not

extend

to products

that have been misused,

neglected, altered or repaired without factory authorization during the warranty

period.

Operating

conditions beyond our control such as improper voltage,

excessi ve ambient temperatures, or other conditions that would affect the

performance

Of

life of the product will also cause the warranty to become

void.

Permission to return parts for warranty repair must be obtained, and all

returns must be prepaid factory. If, after examination, the product or part is found

to be defective,

it

will be repaired or replaced on a no-charge basis and returned.

On the other hand,

if

it

is determined that

the

warranty has not been breached by

Arbe

Machine Mfg.,

Inc., then the usual charges for repair or

replacement

will

be

made.

Parts or products that are obsolete or those

made

to special order are not

returnable.

This limited warranty applies only to the

above

and

is

for

the period set

forth. Arbe Machine Mfg ..

Inc.ts

maximum

liability

shall not, in any case, exceed

the contract price for the product, part, or component claimed to be defective; and

Arbe Machine

Mfg ..

Inc. assumes no liability

at

all

for

any

special.

indirect,

or

consequential

damages

arising from

defecti ve equipment.

TlmRE ARE NO WARH,ANTIES IMPLIED OR EXPRESSTm THAT

EXTEND BEYOND THOSE CONTAINED IN TInS LIMITED WARRANI'Y.

Table of contents

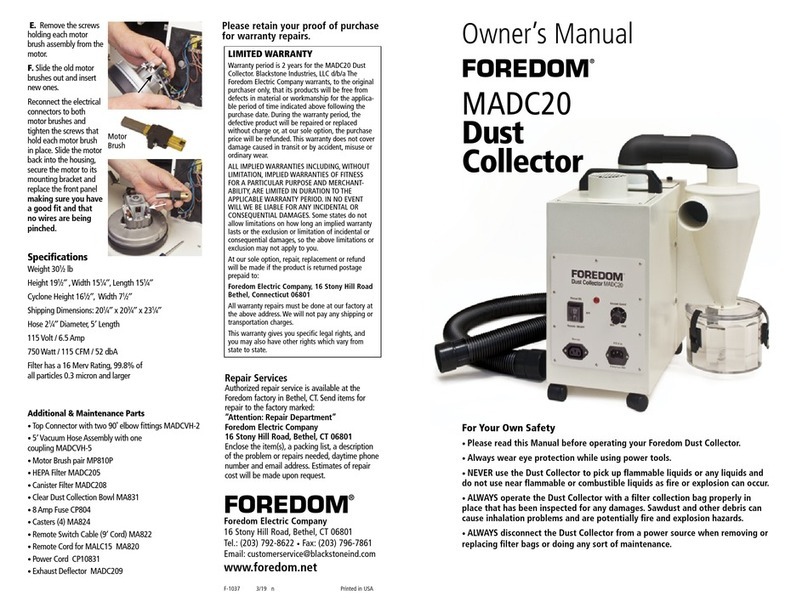

Other ARBE Dust Collector manuals

Popular Dust Collector manuals by other brands

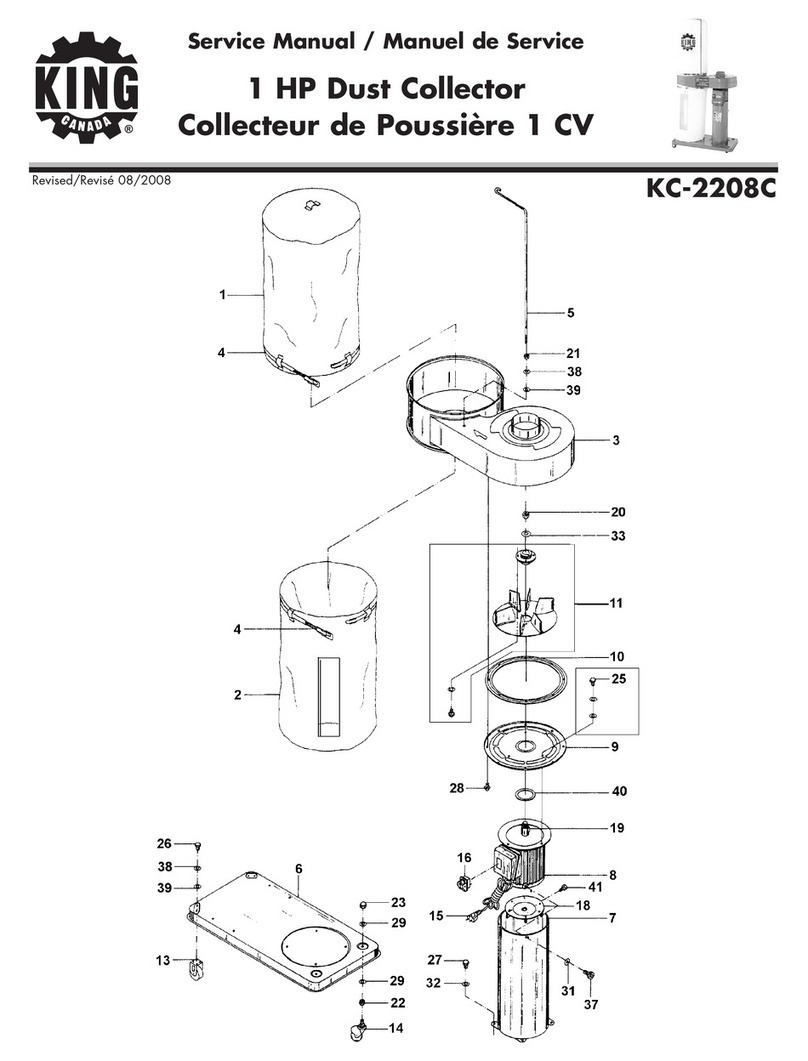

King Canada

King Canada KC-2208C Service manual

King Industrial

King Industrial KC-6150C instruction manual

Baileigh Industrial

Baileigh Industrial DC-2100C Operator's manual

Craftsman

Craftsman 152.213361 owner's manual

National

National 3402 instruction manual

Storch

Storch Cover Quick Wall installation manual

Oneida Air Systems

Oneida Air Systems Super Dust Gorilla owner's manual

Jet

Jet IAFS-1700 Operating instructions and parts manual

Central Machinery

Central Machinery 31810 Owner's manual & safety instructions

Husqvarna

Husqvarna DC 6000 Operator's manual

AAF

AAF RotoClone W Installation, operation and maintenance manual

Oneida Air Systems

Oneida Air Systems XXVM001500 owner's manual