ARCA DYNAMIC User manual

DYNAMIC

Vers. D 10/2011

Labelling machine

User’ s Manual

Rev. Description Date

D New control unit with graphic display 10/2011

MUD00000

2/28

GB

MUD00000

!

ARCA ETICHETTE S.p.A.

Via Edison, 119

20010 Marcallo - MI - Italia

Divisione SISTEMI

Via Pacinotti 20010 Marcallo - MI - ITALIA

Tel. +39-02-97231.1 Fax +39-02-97231.401

www.arca.it

3/28

GB

Thank you for having chosen a

machine manufactured by ARCA Etichette S.p.A.:

this equipment has been designed

and built using state of the art technologies and procedures in order to guarantee lasting reliability

and the maximum safety

for its users.

For a correct use of the labelling machine it is advisable to read this manual thoroughly

and follow the indications given. All the supplied documentation related to the equipment

- and particularly this manual - must be accurately stored for future reference.

MUD00000

38

MUD00000

Rev. D - 10/ 2011

4/28

GB

© 2006 ARCA ETICHETTE S.p.A.

All rights reserved

This publication or any part of it cannot be reproduced, stored in any kind of processor,

transmitted, transcribed or translated in any common or software language, in any form

or with any means be they electronic, mechanical, magnetic, optical, chemical, manual or

other,

without the previous written authorisation of ARCA Etichette S.p.A

ARCA Etichette S.p.A does not issue guarantees on the contents of this publication and

it (specically) denies

any implicit guarantee, commercial guarantee or its adaptability to any object. Furthermore

ARCA Etichette S.p.A reserves the right to revise this publication and modify its contents

without previous

notice to persons or organisations.

GB

This manual is made up of pages

MUD00000

5/28

GB

Summary

1.Introduction ....................................................................................................6

2.General information .......................................................................................7

3.Adjustments....................................................................................................13

4.Cleaning of the labeller..................................................................................23

5.Labelling machine troubleshooting..............................................................27

MUD00000

6/28

GB

1. Introduction

The correct and safe operations of the labelling machine is ensured just in case it is employed according to

what indicated in this manual and, as a general rule, in the documentation supplied with the machine.

Therefore it is extremely important to read thoroughly and accurately keep the documentation supplied with

the machine.

Though the labelling machine is equipped with all necessary security devices, the risks due to a wrong use of

the equipment cannot be avoided.

1.1. Personnel authorised for assistance

Any intervention and extraordinary maintenance on the machine can be performed by trained personnel only,

that is by ARCA Etichette S.p.A. or by personnel authorised by them.

Please call ARCA Etichette S.p.A. Customer Service for information on the personnel authorised to perform

interventions on the unit.

1.2. Communications with ARCA Etichette S.p.A Customers’ Care Service

To solve any problem deriving from the use of the machine, please contact ARCA Etichette S.p.A asking for the

Customers Care Service Centre.

In order to obtain a quick and accurate solution of the problem, please indicate the following data:

- labelling machine model;

- code number;

- detected defect;

Description of the products presenting labelling defects (if any);

Description of the labels presenting labelling defects (if any);

Description of possible attempt made to solve the problem, performed by personnel of the customer.

7/28

MUD00000 GB

2. General information

Summary

2.1. Machine description...................................................................................8

2.1.1.Principal functional groups of the labeller ----------------------------------------------------------------- 8

2.2. foreseen use of the labelling machine .....................................................8

2.3.Identication data of the labelling machine..............................................9

2.4.Identication data of the control unit ........................................................9

2.5.General safety prescriptions......................................................................10

2.6.Security systems.........................................................................................11

2.7.Glossary .......................................................................................................11

8/28

MUD00000

A

B

C

E

D

F

GB

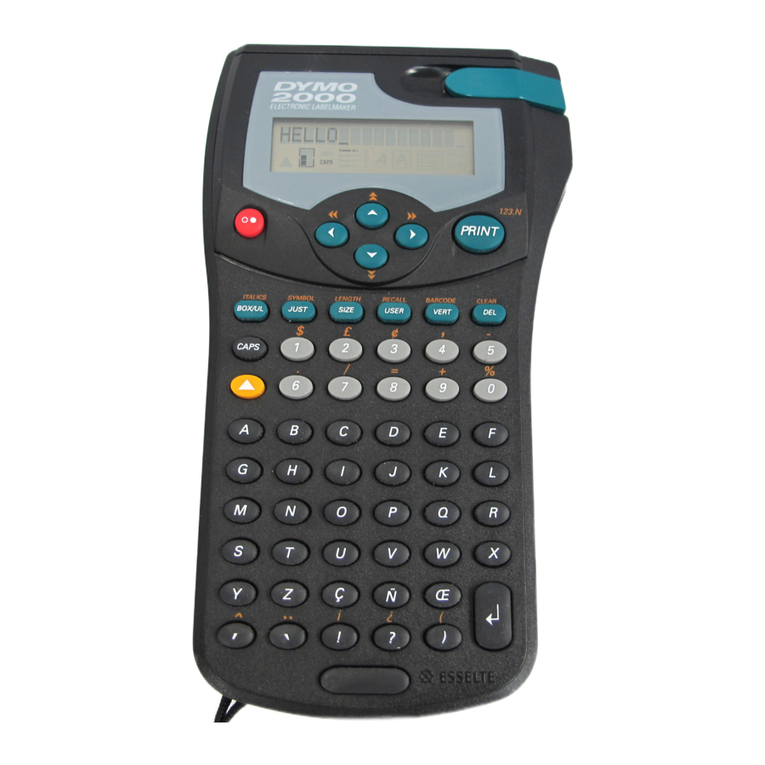

2.1. Machine description

The labelling machine is an automatic application machine t for the solution of any labelling problem. This

machine is an high precision device that enables, by means of a wide range of applicators, to label any kind of

product (bottles, tanks) ensuring high quality results.

The machine is pretty compact an modular, in order to enhance its insertion and moving on already existing

lines.

The whole essential functions of the labelling machine are included in a single control unit (it depends if the

labelling machine is inserted in a system or not), or in a control panel. Please refer to the related section of this

manual for the description of these functions.

The labelling machine can be equipped with different kind of applicators according to the type of product to

label, to the related position of the product according to the labelling machine and the position of the label on

the product.

The different kind of applicators are described in the related manuals.

2.1.1.Principal functional groups of the labeller

A. Reel holders.

B. Rewindind group

C.Transport group

D.Application device

E. Sensor reading labels

F. Control unit

2.2. foreseen use of the labelling machine

The labelling machine is used to work with label reels with a denite size.

The silicon support band of the labels is unwound by the reel and transported on the blade which allows the

lm removal. The silicon band recovery is carried on by means of the rewinder..

ATTENTION! ARCA Etichette S.p.A. declines any responsibility for damages to persons or things deriving

from a wrong use of the machine. Carefully follow the instructions given in this manual for a correct and safe

use of the machine.

ARCA ETICHETTE SPA

DIVISIONE SISTEMI

Via Pacinotti

20010 MARCALLO (MI) - ITALY

MODEL:

S/N:

YEAR:

ARCA ETICHETTE SPA - DIVISIONE SISTEMI

Via Pacinotti - 20010 MARCALLO (MI) - ITALY

MADE IN ITALY

M

O

DEL:

S/N:

YEAR

:

A

R

C

A ETI

C

HETTE

S

PA - DIVI

S

I

O

NE

S

I

S

TEM

I

V

ia Pacinotti - 20010 MAR

C

ALL

O

(MI) - ITALY

MADE IN ITALY

A

RCA ETICHETTE

S

P

A

D

IVI

S

I

O

NE

S

I

S

TEM

I

Vi

a

P

ac

i

nott

i

20010 MARCALLO

(

MI

)

- ITAL

Y

ARCA ETICHETTE SPA

DIVISIONE SISTEMI

Via Pacinotti

20010 MARCALLO (MI) - ITALY

MODEL:

S/N:

YEAR:

ARCA ETICHETTE SPA - DIVISIONE SISTEMI

Via Pacinotti - 20010 MARCALLO (MI) - ITALY

MADE IN ITALY

M

O

DEL:

S/N:

YEAR

:

A

R

C

A ETI

C

HETTE

S

PA - DIVI

S

I

O

NE

S

I

S

TEM

I

V

ia Pacinotti - 20010 MAR

C

ALL

O

(MI) - ITALY

MADE IN ITALY

A

RCA ETICHETTE

S

P

A

D

IVI

S

I

O

NE

S

I

S

TEM

I

Vi

a

P

ac

i

nott

i

20010 MARCALLO

(

MI

)

- ITAL

Y

9/28

MUD00000 GB

2.3. Identication data of the labelling machine

The identication of the labelling machine you purchased can be performed through the identication plate.

The identication plate contains these data:

• machine type

• code number of the labelling machine;

• labelling machine production year.

2.4. Identication data of the control unit

The identication of the control unit can be performed by reading the identication plate.

The identication plate contains these data:

• code number of the control unit;

• supply voltage;

• absorbed current.

!

!

10/28

MUD00000 GB

2.5. General safety prescriptions

THE USE OR MAINTENANCE OF THE MACHINE FROM UNAUTHORISED

OR UNTRAINED PEOPLE IS FORBIDDEN.

The levels of the operators suggested to carry on specic operations described in the present manual are listed

as follows.

Then, beside the operation description, the letter is indicated, followed by a number relative to the level corre-

sponding to the competence.

C = machine operator

M = maintenance operator

(for example, M2 corresponds to second-level Maintenance operator)

When using the machine, it is necessary to observe the local and community laws and norms relative to safety

and environment safeguard.

C1 = First-level machine operator

Unskilled personnel, without specic competence, able to carry on simple operations only, that is, the

machine use by means of the controls positioned on the push-button panel and loading and unloading opera-

tions of the materials used during the production, with enabled protections (unauthorised to use the machine

in JOG with open protections);

C2 = Second-level machine operator

Unskilled personnel, able to carry on the operations of level C1 and work with disabled protections

and safety measures to carry out simple adjustment and start operations or production reset after a forced

interruption;

M1 = Mechanic maintenance operator

Qualied technician, able to operate the machine in normal conditions, with disabled protections and

safety measures, to act on the mechanic parts in order to carry on all necessary adjustments, maintenance

operations and repairs. He is not authorised to carry on operations on electric installations when the voltage is

on.

M2 = Electric maintenance operator

Qualied technician, able to operate the machine in normal conditions, with disabled protections and

safety measures; he is in charge of all electric adjustment and maintenance operations or repairs. He is able

to work in electric cabinets and connector blocks when the voltage is on

M3 = Constructor’s technician

Qualied technician, authorised by the Constructor to carry on complex operations in particular situa-

tions, as agreed upon with the user.

IMPORTANT NOTE: Except for level M3, the above-mentioned table is approximate, depending on the type

of machine and/or factory; in addition, the user may have at his own disposal personnel combining competence

M1 and M2 or C1, C2 and M1.

IT IS ABSOLUTELY FORBIDDEN TO OPERATE THE MACHINE IN

AUTOMATIC MODE WITH DISABLED PROTECTIONS.

IT IS ABSOLUTELY FORBIDDEN TO DISCONNECT THE SAFETY

DEVICES INSTALLED ON THE MACHINE

THE ADJUSTMENT OPERATIONS, WHEN THE SAFETY CONDITIONS

ARE REDUCED, MUST BE CARRIED ON BY ONE PERSON ONLY. THE

ACCESS TO THE MACHINE FROM UNAUTHORISED PERSONNEL IS

FORBIDDEN.

!

11/28

MUD00000 GB

THE WASHING OPERATIONS MUST BE CARRIED ON ONLY IF

PROVIDED IN THE PRESENT MANUAL AND WITH DISCONNECTED

ENERGY SEPARATION DEVICES (ELECTRIC, PNEUMATIC

ENERGY).

DO NOT CHANGE, FOR ANY REASON, THE MACHINE PARTS TO

ADAPT NEW DEVICES. IN CASE OF MALFUNCTIONING DUE TO THE

INOBSERVANCE OF THE ABOVE-MENTIONED PRESCRIPTIONS,

ARCA ETICHETTE S.p.A. DECLINES ALL RESPONSIBILITIES.

The machine must be correctly connected, as per diagrams attached to the manual.

2.6. Security systems

The labelling machine is equipped with active and passive security devices. All these systems enable the ma-

chine to prevent dangerous situation for people operating on it or around it.

2.7. Glossary

In this short glossary, commonly used terms are indicated, such as:

• detaching blade or detaching tongue: metal support to remove the lm of the label from the support silicon

paper;

• photo-stop: sensor which detects the space between two labels

• pre-ejection: distance in mm between the free end (without lm) of the label and the detaching blade;

• transmission rollers: these rollers transport the paper and maintain its correct tension;

• coil-holders: rollers which support the labels coil and the coils of the rewound silicon paper;

• pulling units: motorised rubber roller and idle knurled roller to pull the paper;

• re-winding device: roller which enables to recover the silicon paper

• Effective ray diameter: diameter of the action area (it can be detected by the intersection of an imaginary plan

with the cone) in which an object can be detected.

• Working distance: maximum detection distance which grants the reading by the photocell.

• Working frequency: Maximum frequency of the status changes performed by the photocell

• Dark pulse: The output of the photocell is activated when the receiver is not struck by the light ray.

12/28

MUD00000 GB

13/28

MUD00000 GB

3. Adjustments

Summary

3.1. Setting the label on the product ...............................................................14

3.2. Micro-switch adjustment ...........................................................................14

3.3. Photocell adjustment .................................................................................15

3.4. Adjustment of the transport roller pressure............................................16

3.5. Adjustment of the mechanical sensor for end of roll ............................16

3.6 Label roller replacement.............................................................................17

3.7. Paper path...................................................................................................18

3.7.1 Paper path with xed or articulated peeler--------------------------------------------------------------- 18

3.7.2 Paper path with “Concorde” peeler ------------------------------------------------------------------------- 19

3.7.3 Paper path with Hot print unit -------------------------------------------------------------------------------- 19

3.8 Take up roller ...............................................................................................20

14/28

MUD00000 GB

3.1. Setting the label on the product

The machine must be centred on the product to be labelled (according to the needs) both horizontally and

vertically, acting on its support.

The position adjustment of the labelling machine must be performed according to the kind of application de-

vice.

An electronical label pre-ejection adjustment device is mounted on the control unit.

The pre-ejection is adjusted bycontrol unit; see the control unit section for more details.

It is possible to evaluate the effect of the adjustment only after having performed at least to dummy ejections.

The correct pre-ejection value is strictly connected to the kind of application device employed; refer to the ap-

plication device manual for more details.

3.2. Micro-switch adjustment

Perform the following operation to adjust the label positioning micro-switch:

• loose the thumbscrew and pull the micro-switch;

• lift the plug and insert the labels ensuring that the micro-switch

is set on a label;

• feed the labels by hand until the micro-switch is between two

labels; the led set on the micro-switch must switch on;

15/28

MUD00000 GB

• should the led fail to switch on, introduce a socket head

spanner (2 mm) in the hole of the adjustment device in order

to change the pressure of the balancing device which detects

the space between labels;

• for a further check make the labels go back and forth by hand: the led set on the micro-switch must switch on

when it is on the space between two labels, and go off when on a label;

3.3. Photocell adjustment

In order to adjust the labels positioning photocell, perform the following procedures:

• Insert the label tape in such a way that the marker of the optical

axis lies on the free bearer or between labels;

• press the button until bpth LEDs ash simultaneously.

• release the button. Teach-in has started. Leds ash alterna-

tingly.

• Briey press button again. Teach-in is nished.

• Green LED illuminates. Sensor is ready.

1

2

5

4

3

1

2

3

16/28

MUD00000 GB

3.4. Adjustment of the transport roller pressure

In case of wrong feed of the labels (wrong application during the labelling) perform the following indications:

• disconnect the power supply and pneumatic if it foresees;

• remove the shed (3) loosing the screws;

• unhook the transport roller;

• unloose the cheese head screws (1) and rotate the eccentric

axis (2) adjusting the roller pressure;

• x the two cheese-head screws;

• reassemble the shed (3).

3.5. Adjustment of the mechanical sensor for end of roll

The end-of-roll device (optional), enables to warn the user when the label coil is approaching to the end

IThe device is essentially composed by an adjustable rod which (1), pushed by a spring, must follow the external

edge of the labels coil (2)

The adjustment of the bending for this rod, enables to adjust the minimum quantity of labels which signals to

the control unit the end-of-roll.

In order to adjust this device, perform the following operations:

• Set a label coil with few labels(2), (as much as it is necessary

to switch on the end of coil alarm)

• Position the end-of-coil rod in reading position(1) (rod leaning

on the coil)

• Loosen the locking knob (3) and turn the ring nut (4) clockwi-

se or anticlockwise until you hear the microswitch tripping(5).

Tighten the locking knob.

17/28

MUD00000 GB

3.6 Label roller replacement

The labels roller must have t dimensions as described in section 3.

To replace the labels roller:

A. unhook the pulling roller;

B. loose the block gear;

C. if it is not nished yet, break the label support silicone band

at any point;

D. remove the paper left on the paper roller;;

E. remove the old roller;

F. set the new roller; if the inner diameter of the roller is 45,75

mm no further adapters are necessary, should it be 76.2 mm it is ne-

cessary to use the t adapter;

G. screw the blocking gear;

H. reassemble the end-of-coil sensor rod in the reading position

(see further pages for more details)

I.

18/28

MUD00000 GB

3.7. Paper path

To make the labels perform the correct paper path, follow the instructions given:

A. unwind the labels coil for at least a meter;

B. remove the lm from the labels for about 0,5 mt;

C. make the paper pass as shown in the gure, it depends if the labelling machine is a left or a right version,

paying attention that the labels support silicon band is free of labels after the detaching blade.

- EXTERNAL Reeling

- INTERNAL Reeling

3.7.1 Paper path with xed or articulated peeler

19/28

MUD00000 GB

3.7.2 Paper path with “Concorde” peeler

3.7.3 Paper path with Hot print unit

20/28

MUD00000 GB

3.8 Take up roller

To block the paper on the take up roller, follow the indication given:

A. insert paper and rotating it by hand for some turns until the paper is blocked;

B. rotate the take-up roller by hand up to complete tension of the paper.

Table of contents