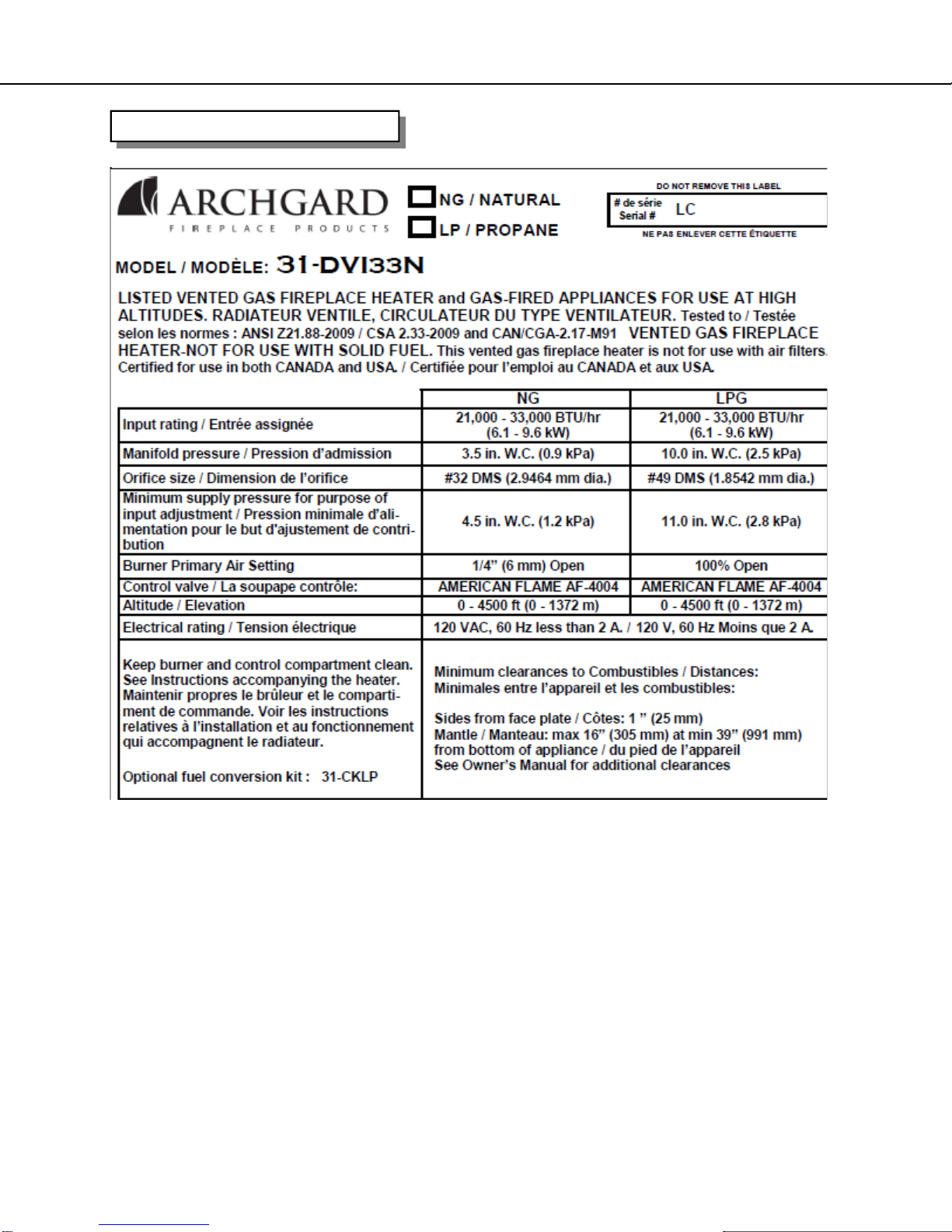

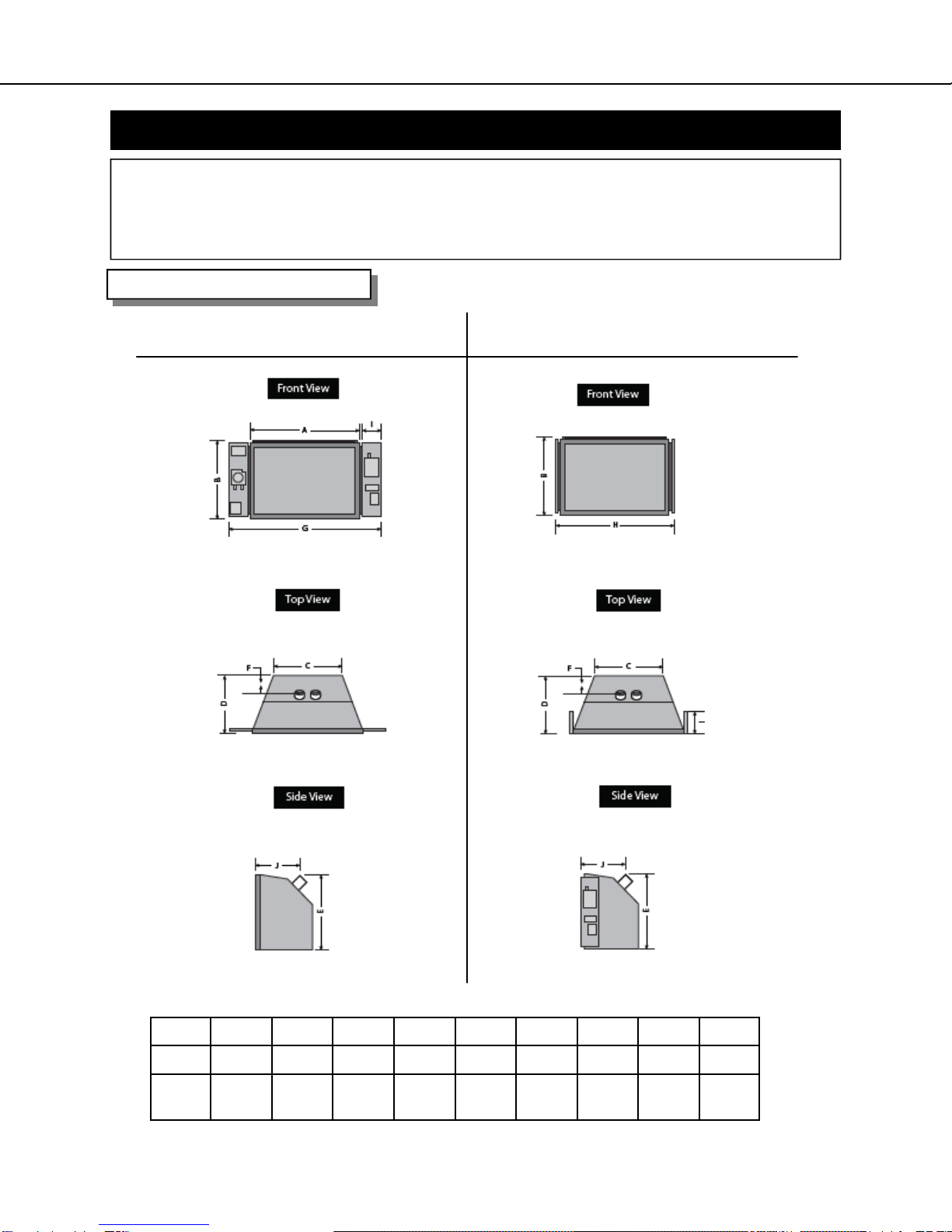

Archgard 31-DVI33N Owner's manual

Other Archgard Gas Heater manuals

Archgard

Archgard Optima Owner's manual

Archgard

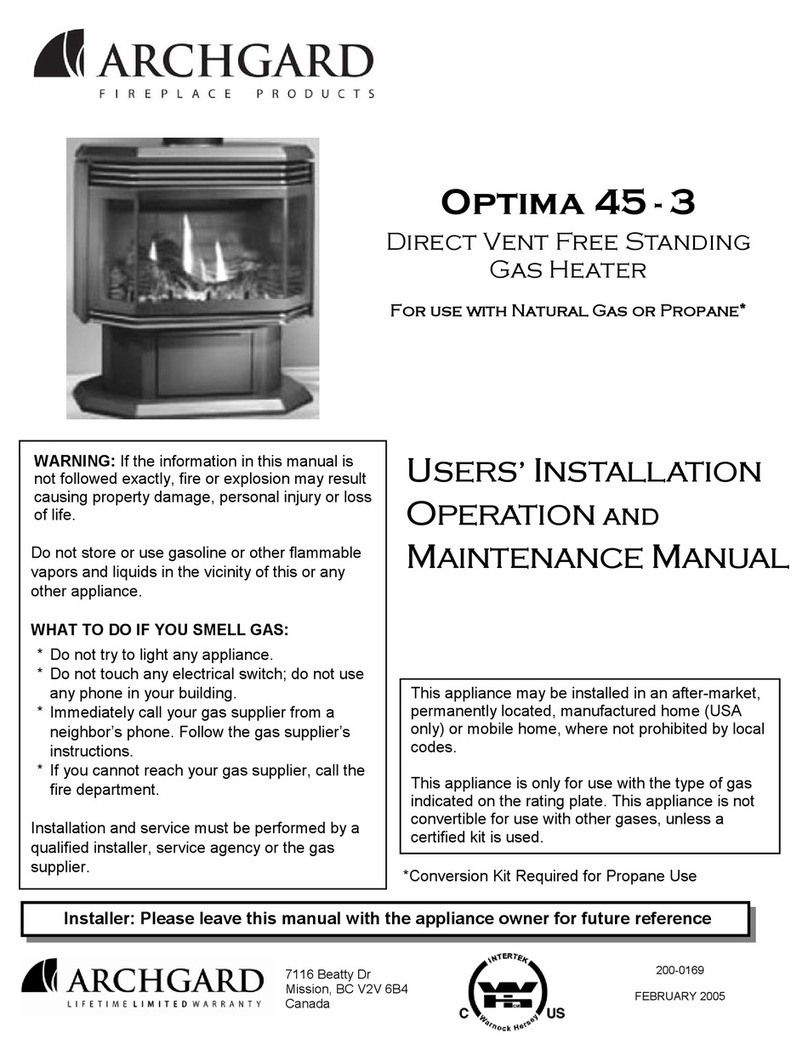

Archgard Optima 45 - 3 Maintenance and service guide

Archgard

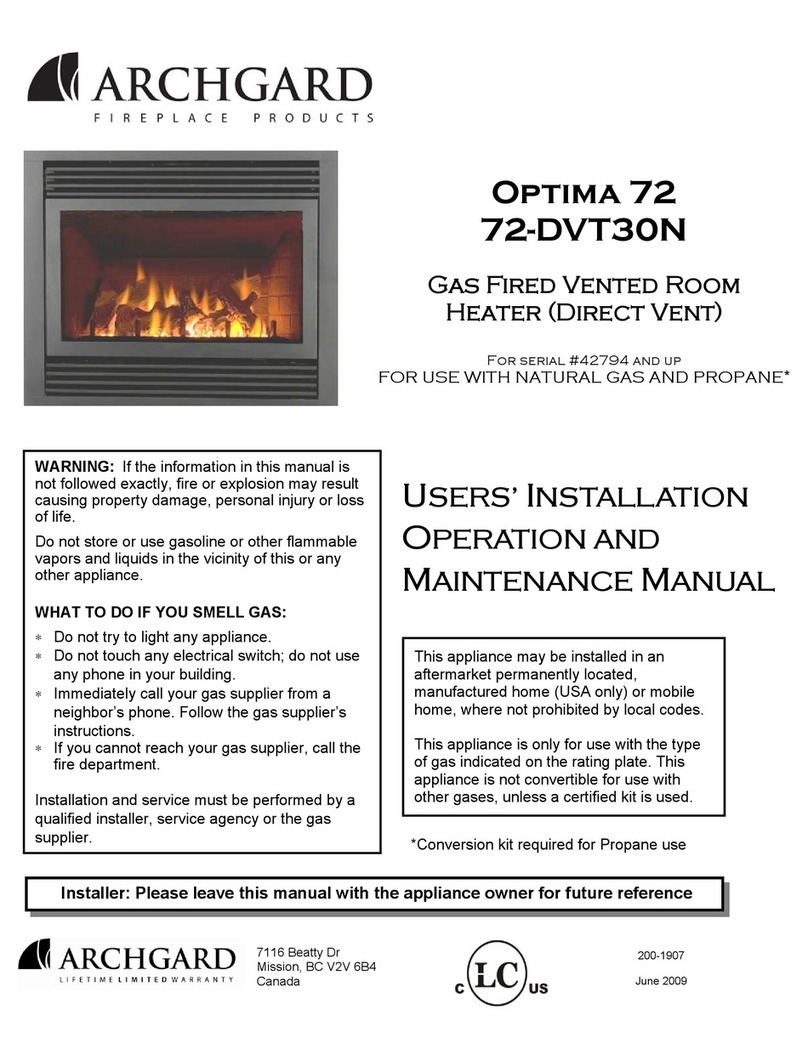

Archgard Optima 72-DVT30N Owner's manual

Archgard

Archgard 3600-DVTR24N-2 Owner's manual

Archgard

Archgard Optima 40 Owner's manual

Archgard

Archgard Optima 45-1 Owner's manual

Archgard

Archgard 31-DVIE33C Owner's manual

Archgard

Archgard 31-DVIM33C Owner's manual

Popular Gas Heater manuals by other brands

Desa

Desa ROPANE CONSTRUCTION HEATERS owner's manual

Desa

Desa BCLP375 owner's manual

Robur

Robur Line F1 Series User, installation and service manual

Superior

Superior BGE18NV Installation and operation instructions

Dru

Dru Room-sealed atmospheric gas-fired heating... user manual

klover

klover TKR 35 user guide

Rothenberger Industrial

Rothenberger Industrial 035984 instruction manual

Hargrove

Hargrove Timberland Glow Operation and installation guide

Kinder

Kinder Cameo BF Installation and maintenance instructions

Qlima

Qlima GH 438 B-2 Directions for use

Desa

Desa 125-R owner's manual

Gasmate

Gasmate AH100 Series instructions

Brant Radiant Heaters

Brant Radiant Heaters QTD Series User instruction

Medallion

Medallion MBP20TLB OWNER'S OPERATION AND INSTALLATION MANUAL

Sealey

Sealey LP35.V5 instructions

Italkero

Italkero Falo Evo User manual and assembly instructions

Desa

Desa 30LP owner's manual

Williams

Williams 2509822A owner's manual