User, Installation and Service Manual for F1 Gas Unit Heaters 5

SECTION 2 - GENERALITY AND CHARACTERISTIC

OPERATION OF THE UNIT

- The F1 gas fired air heater is an independent heater appliance with airtight combustion circuit

and forced air draft.

- It’s designed for an indoor installation - inside the area to be heated.

-It’s adjustable for the use of Natural Gas (G20) or LPG (G30/G31).

-The combustion circuit is airtight regarding heated room and conforms the standard EN 1020 for

the C type appliances: the air inlet of the combustion air and the flue exhaust are outdoors and

are ensured through the operation of combustion blower. The appliance is certified either for the

B type installations, where is allowed combustion air inlet from indoors (from the area to be

heated).

-A room thermostat, (not supplied with the unit) controls the heater operation.

-When the thermostat is turned on the flame control box, after the pre-purge period (about 40

seconds), ignites the burner.

-The flame sensor controls the ignition of the burner. If the flame does not appear the flame

control unit locks out the heater:

-The combustion products pass through the heat exchangers, the air flow given by the axial fan

provides warm air to the room.

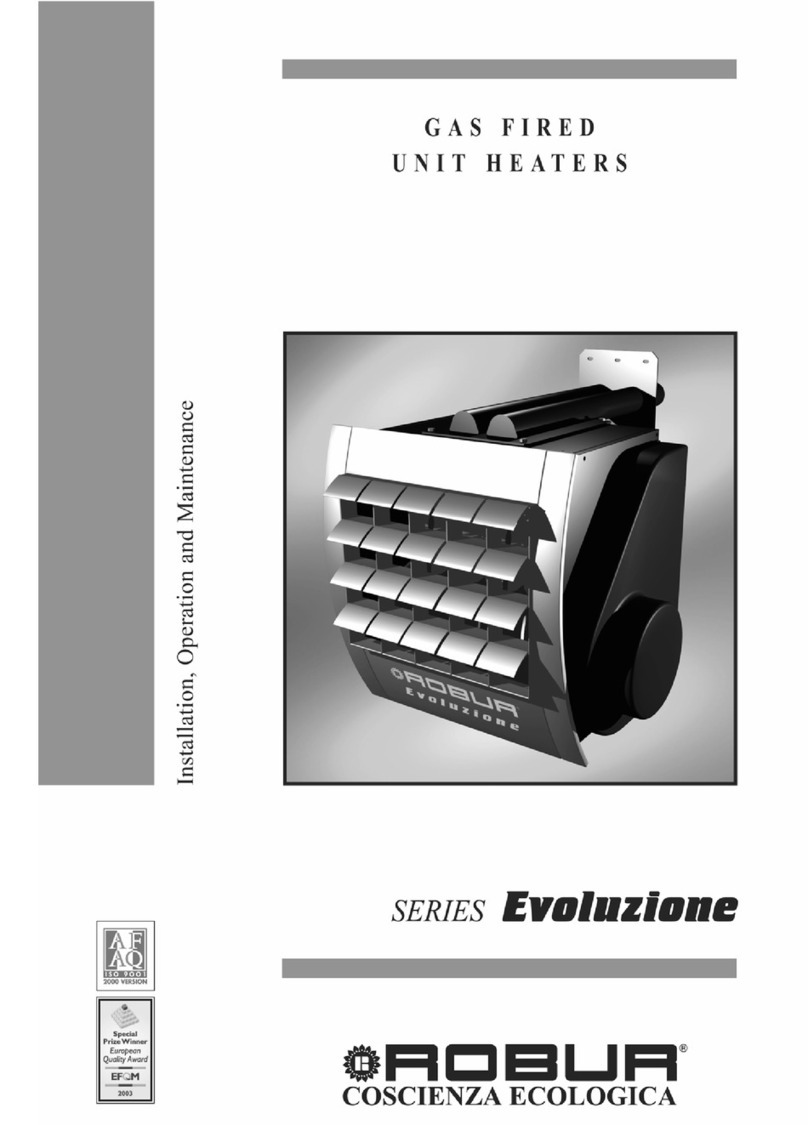

-The airflow direction is regulated by means of adjustable louvres. A ‘’vertical louvres kit’’ is also

available on request for horizontal regulation of the airflow.

-The fan control thermostat allows the axial-flow fan to start automatically only when the heat

exchangers are hot and to turn off when they are cold. This prevents cool air being blown into

the room

-If heat exchangers overheat due to malfunction, the temperature limit thermostat cuts off the

supply to the gas valve, thus interrupts fuel flow and turns off the main burner

NOTE

After removing the cause of overheating, Qualified service engineer should carry out resetting of

the temperature limit thermostat,

-Ahead of the burner is installed the flue fan which makes the air-gas mixture and forces draft of

the exhaust flues.

-In case of obstructions in the intake duct or flue fan malfunction, a differential pressure switch

closes the gas valve and consequently stops fuel flow to the burner.

-In the summer time it’s possible to activate only the axial fan to provide pleasant and refreshing

air movement in the room. (see Section 4 - Paragraph “Summer”).

CONSTRUCTIVE CHARACTERISTICS

-premix burner made of stainless steel

-high head blower; models F1 51/61/81 are provided with electronic board that controls and

guarantees constant speed of the blower;

-cylindrical combustion chamber made of stainless steel

-heat exchanger patented by Robur made of special aluminium alloy, fining horizontally on the

air side and vertically on the flue side with extremely high capacity of thermal exchange

-insulated steel casing painted with epoxy powders

-axial fan with high air flow capacity

-according to the norms in force regarding the radio interference

-heat recovering post-ventilation