p3

1. INTRODUCTION

The converters of the series TPIs xxx are fully programmable measure inter-

faces, extra narrow (7.2mm).

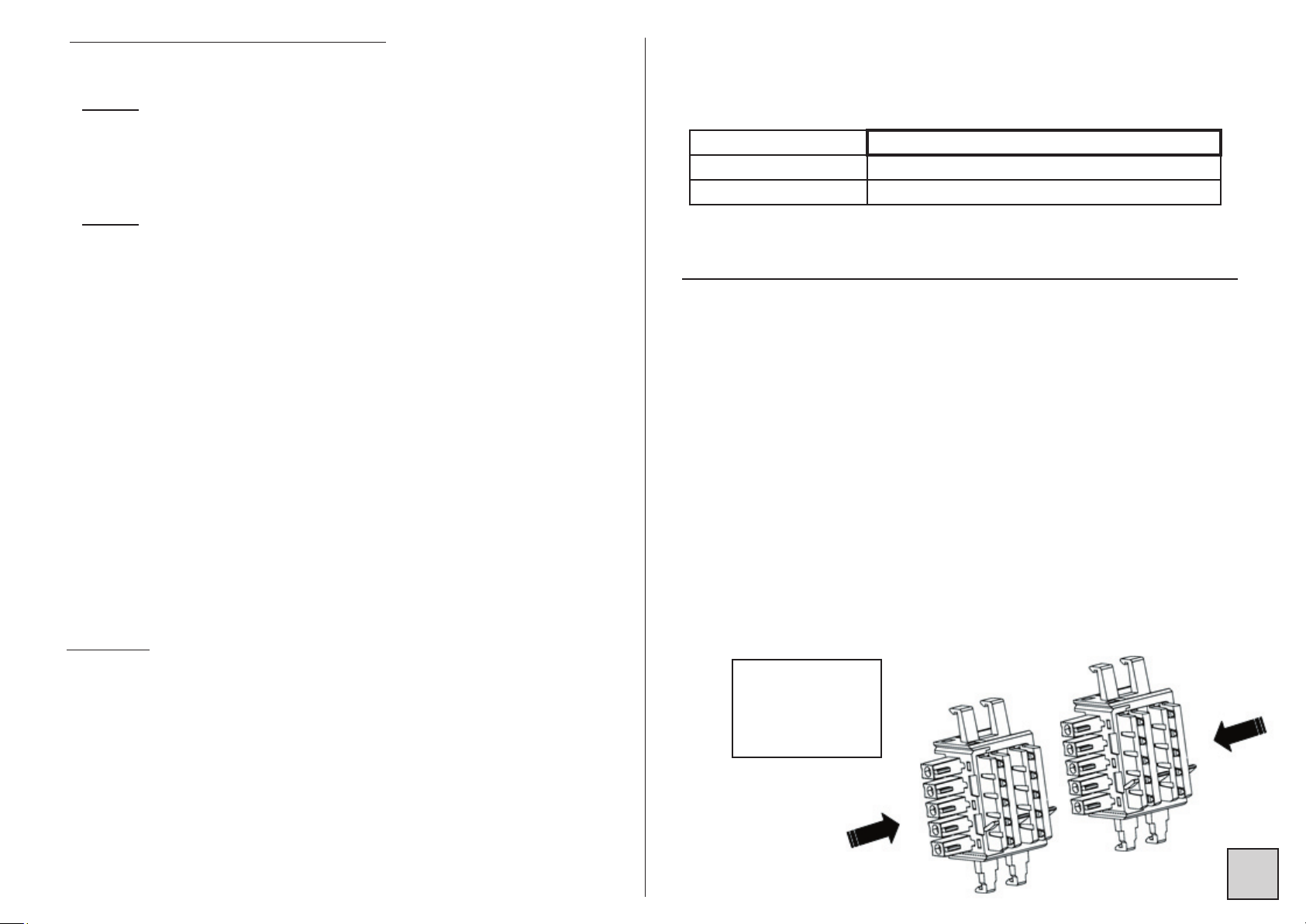

They are mounted on DIN rail (via a 5-points footing which ensures the con-

nection of the supply bus, depending on the models).

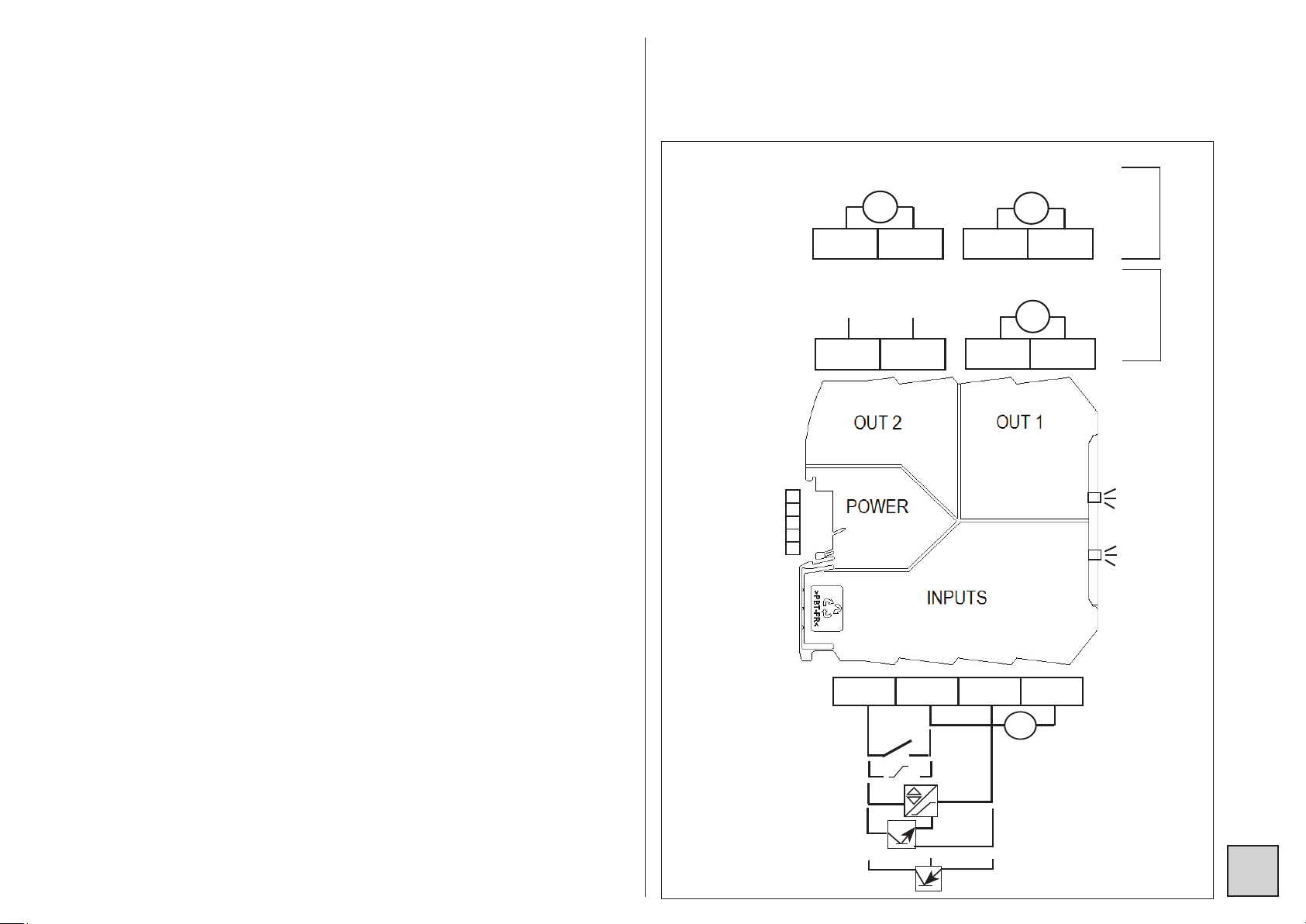

The programming is performed via the µUSB connector located on the front

face, which is to be connected to a computer of the type PC equipped with

the software Slimset.

The TPIs 50/250 have a frequency input measure with possibility of connec-

tion without external components to sensors of the type NPN, PNP, logic,

namur (with sensor rupture detection), contact and alternating up to 500V.

The TPIs 60/260 have 2 independent frequency measure inputs with possi-

blity of connection without external components to sensors of the type NPN,

PNP, logique, namur (with sensor rupture detection) and contact. They can

perform the sum or the substraction of the frequency measures, as well as the

detection of a rotation direction in the case of signals in phase quadrature.

The TPIs 61/261 have in addition to the TPIs 60 and 260 the possibility to

integrate the measure on a time basis allowing this way to transform an ins-

tant magnitude into a cumulated magnitude, with saving of the value in case

of power supply cut.

Several functions (min. and max. zero reset , zero reset of the integrator,

function Hold, etc ...) can be performed by a logic input (with one of the two

frequency inputs programmed as logic input).

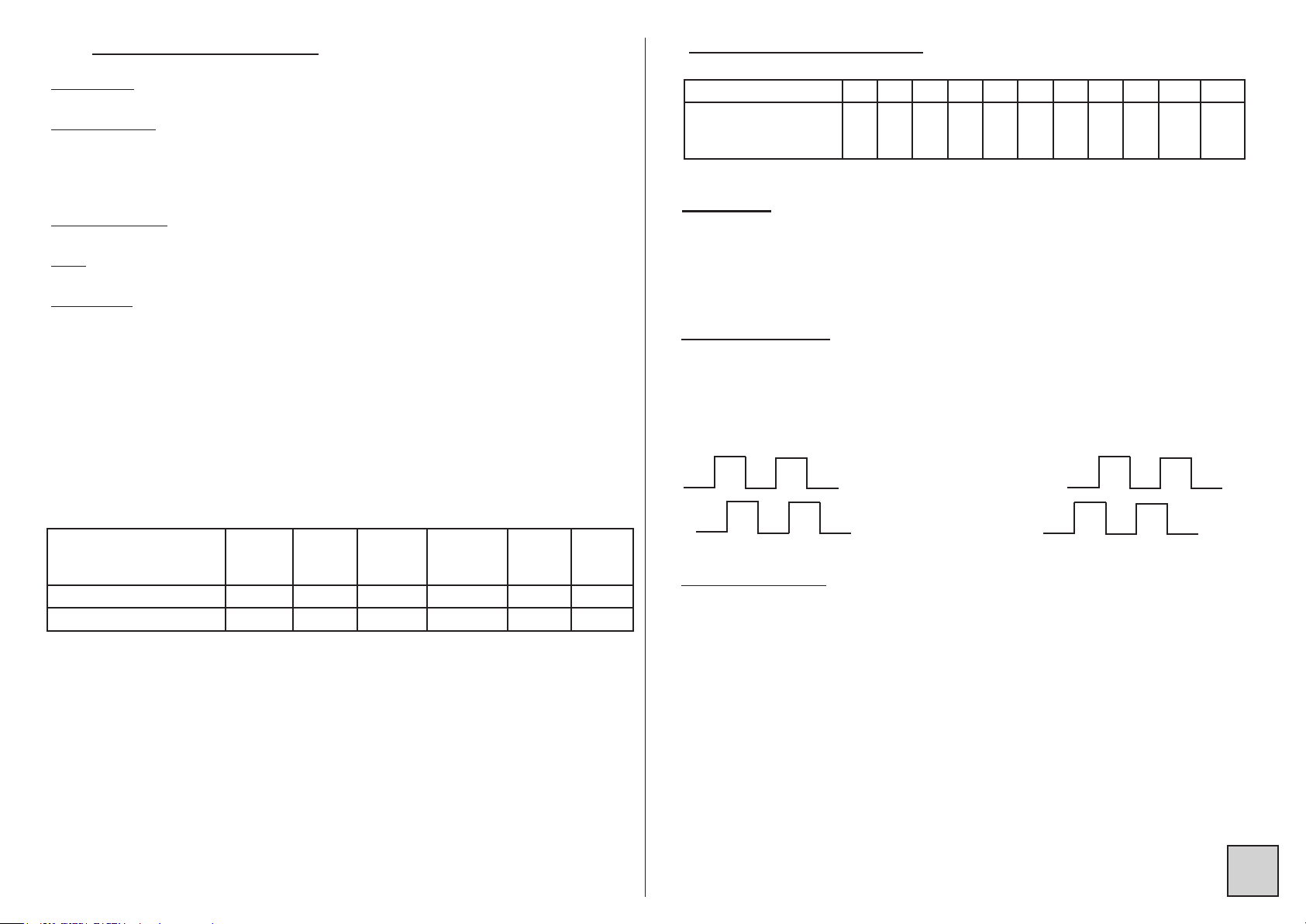

Coding:

TPIs Y XX

Type of output:

Nothing: 1 insulated active ana-

log output, current or voltage

2 : 2 insulated active analog

outputs, current or voltage

Type of input:

50: 1 frequency input (all types of sen-

sors + alternating)

60: 2 frequency inputs (all types of

sensors except alternating), calculation

function

61: 2 frequency inputs (all types of

sensors except alternating), calculation

function + integrator.

1.1 General features

Operating temperature ....................... -25°C to +70°C

Storage temperature .......................... -40°C to +85°C

Power supply......................................16.8 to 31.2 Vdc

Max. power draw ................................1.2W

Max. internal dissipation.....................0.6W

Galvanic partition................................ 2.5kV-50Hz-1mn between supply, inputs,

analog output n°1, analog output n°2,

µUSB

Supply for 3-wire sensor..................... 15Vdc ±10% at 20mA (max. current 30mA in

case of short-circuit)

Standard sampling time...................... 100ms + 1 period of the measured signal

Listed

Installation in ATEX / IECEx area 2

Installation in division 2 (hazardous locations)

Compliance with standards:

Directive EMC 2014/30/UE ..............EN 61326-1

Directive LV 2014/35/UE ..................EN 61010-1

Standard for CSA electrical safety....CSA C22.2 14-13

..........................................................UL 508 17th ed.

ATEX 2014/34/UE ............................EN 60079-0, EN 60079-15

IECEx ...............................................IEC 60079-0, IEC 60079-15

Hazardous locations.........................CSA C22.2 213

..........................................................ANSI/ISA 12.12.01

Marking:

II 3 G Ex nA IIC T4 Gc

Class I, Div.2, Groups A, B, C, D T4