2

70923

• This tool is for bleeding automotive hydraulic brake systems on most vehicles.

• Designed for use with disc or drum brake systems

• Includes one brake fluid bleeder with hose

• Transparent hose for fluid visibility during draining process

• Convenient hose hanging hook

WARNINGS

SPECIFICATIONS

FEATURES

• Always read the instructions carefully before using the tool

• This brake bleeder is for use with hydraulic brake systems only

• Before each use, inspect the condition of the testing equipment

• To prevent injury DO NOT use damaged equipment

• Ensure the working area has adequate lighting

• This product is not a toy. Keep children and unauthorized persons away from the working area

• Keep working area clean, dry and free from unrelated materials

• DO NOT allow untrained persons to use this tool

• Always wear eye protection that meets OSHA and ANSI Z87.1 standards

• Always wear gloves when working with the tool

• Do not allow the tool to interfere with normal engine moving parts

• Engine exhaust contains carbon monoxide which is a poison

• Disposal: Customers should follow local regulation to handle used/waste parts and chemicals

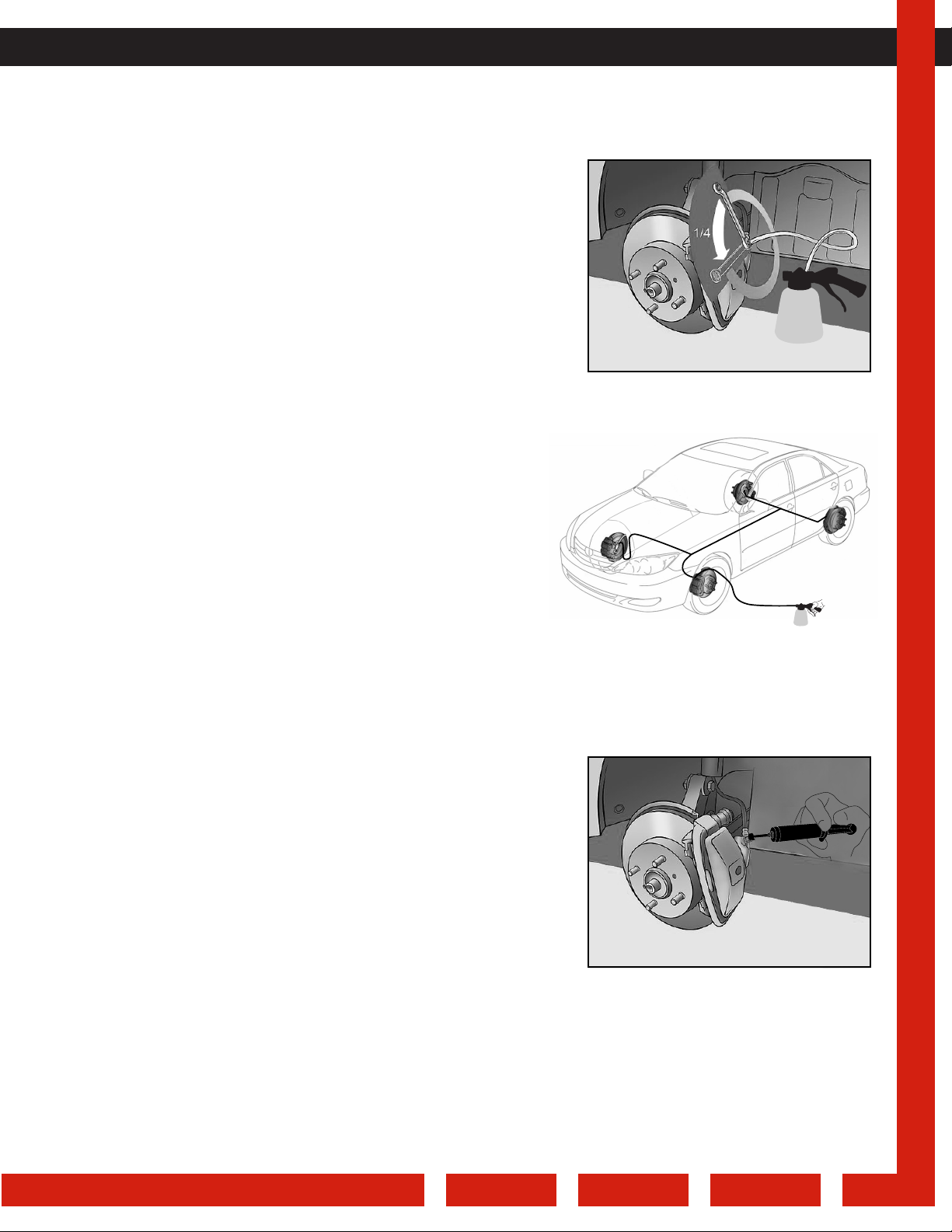

• Be sure to follow manufacturers recommended bleeding sequence while performing procedure. Method

does not eliminate proper sequence.

• Brake fluid is hazardous. Read and follow fluid manufacturer's warnings.

• Brake fluid is corrosive and may damage automobile paint or other surfaces. If fluid spills, flush with water immediately.

Working Pressure

Maximum Air Pressure

Air Consumption

Vacuum

Tank Capacity

Inlet Size

71 - 113 PSI

113 PSI

180 L/min

60%

1L

1/4” BSP

INSTRUCTIONS

Brake Bleeding Procedure

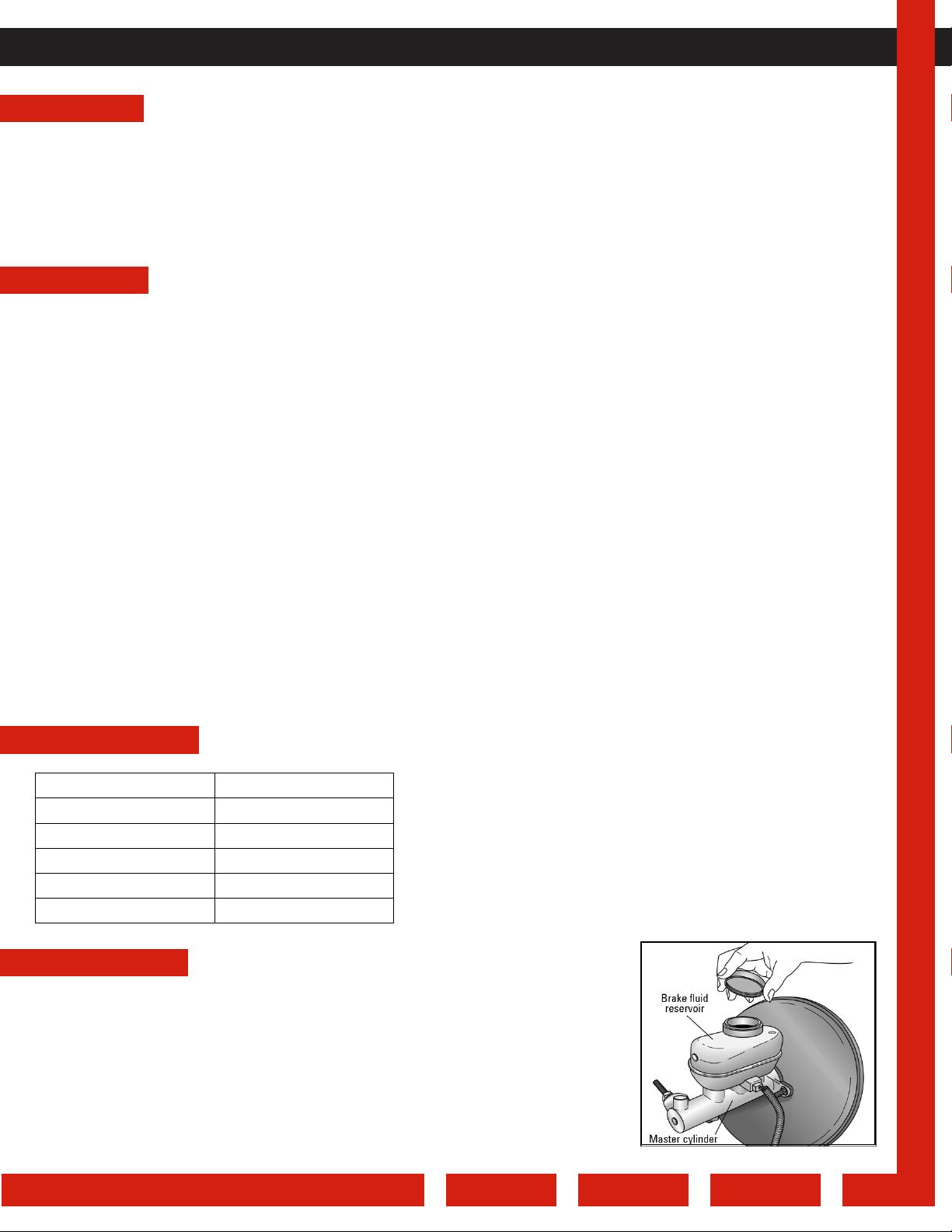

1) Remove the lid of the vehicle’s brake fluid reservoir. Be sure to keep lid removed

until bleeding and refill procedure is finished. This prevents vacuum from

occurring in system that leads to incomplete purging of air from system. (Figure 1)

CAUTION: Brake fluid is corrosive and may damage automobile paint or other surfaces.

If fluid spills, flush with water immediately.

Figure 1