5

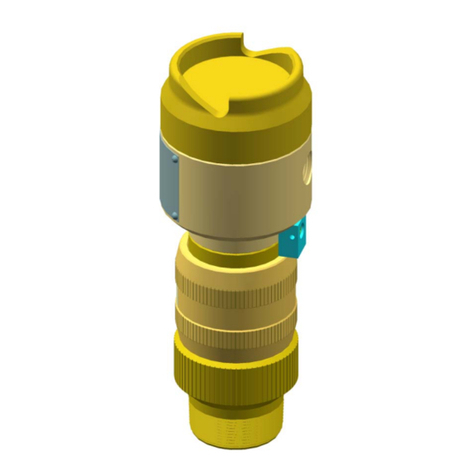

12. Use a pipe wrench on the electrical conduit to tighten it into the female (box) port until proper make-

up is achieved. If this appears to be difficult to achieve, remove the conduit and check for any foreign

matter, thread damage or galling.

13. Attach electrical wires to the Microswitch as per Argus Wiring Instruction sheet (Bulletin No. TB-PS-

002).

Microswitch Manufacturer's Recommended Torque (Maximum)

Mounting Screws…………………3 in-lbs

Terminal Screws…………………..4 in-lbs

Panel Mount Bushing…………….4-6 in-lbs

Caution: Tightening mounting screws above 3 in-lbs changes operating characteristics and increases

the possibility of cracking the case. Applying excessive torque to the terminal screws when attaching

the wires may cause damage to the Microswitch.

14. Install the Cap on the Switch Housing and hand-tighten only. When properly installed, the Cap should

meet the shoulder on the Switch Housing. It is not necessary to wrench tighten the Cap to ensure a

seal.

Caution: Do not over-tighten the Cap, as damage may occur.

15. Once installation is complete, the Pressure Switch should be operated two (2) or three (3) times to

verify the factory settings.

7.0 Operation

7.1 Operating Instructions

Once installation is complete, the Pressure Switch will trip automatically.

•If it is an automatic reset switch, it will reset automatically when the pressure returns to within

normal operating range.

•If it is a manual reset switch, it will reset when the operator pushes the reset button on the top of

the switch.

7.2 Pressure Setting

1. Rotate Access Collar counterclockwise until it hits the upper shoulder of the Switch Housing. This

allows access to the port in the Bottom Sub. The slotted Spring Adjustment Nut should now be

visible.

2. Using a flat blade (Standard) screwdriver, insert the blade into one of the slots and rotate the Spring

Adjustment Nut to either increase or decrease the pressure setting as required. Rotating the Spring

Adjustment Nut clockwise increases the set point, counterclockwise decreases the set point.

Continue adjusting until the desired set point is achieved. Refer to the Argus Pressure Switch

brochure for the available pressure ranges as per the model number.

3. Rotate the Access Collar clockwise until it hits the lower shoulder of the Bottom Sub. The access port

should now be covered to keep out moisture and debris. (In conditions of severe vibration, the

optional Vibration Lock may be purchased and used. Install the Vibration Lock with the pins in one

slot of the Spring Adjustment Nut prior to screwing the Access Collar down).

Caution: Leave the Access Collar in the “down” position after adjustments have been completed.

4. The optional Tamper Seal Block may be purchased and used to prevent anyone from tampering with

the set point once it has been established. To use, simply install the Tamper Seal Block with the caps

crew provided into the hole in the Switch Housing. Run a wire through the holes in both the Tamper