2

Safety Precautions (Continued)

NOTE: This product is equipped with an internal

combustion type engine. Do not use unit on or near

any unimproved, forest-covered or brush-covered

land unless the exhaust system is equipped with a

spark arrester meeting applicable local, state or

federal laws. A spark arrester, if it is used, must be

maintained in effective working order by the operator.

See your Ariens Dealer or engine manufacturer’s

service center.

Operation

DO NOT put hands or feet near or under rotating

parts.

Operate tiller only in daylight or good artificial light.

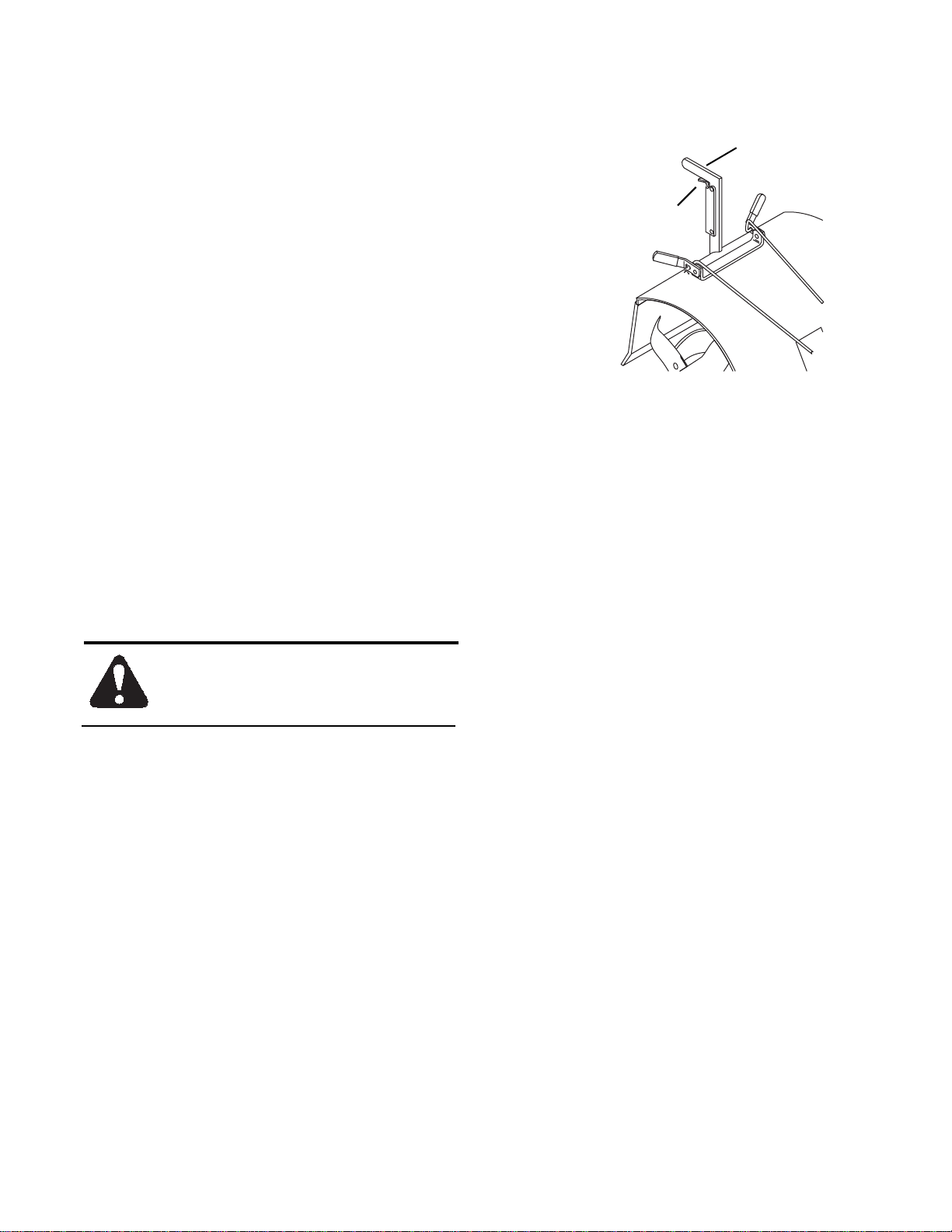

Do not engage tine clutch unless wheel drive is

engaged. Tiller may run away propelled on the high

speed tines.

To begin tilling: lift up on handlebar so tines clear

ground, engage the main clutch, then slowly lower

tines into the soil.

Disengage main clutch, stop engine, wait for moving

parts to stop and remove wire to spark plug before

leaving the operators position, attempting to unclog

tines or make any repairs, adjustments and

inspections. (Except where specifically

recommended by manufacturer.)

Open doors if engine is run in garage or enclosed

areas, exhaust fumes are dangerous. DO NOT run

engine indoors without adequate ventilation.

NEVER allow anyone near unit while it is in

operation. Be familiar with area of operation.

Stay alert for holes, rocks, roots and hidden hazards

in area of operation.

Disengage power to tines when tiller is transported or

not in use.

Watch out for traffic when crossing or operating near

roadway.

DO NOT touch engine or tiller drive parts which are

hot from operation. Before attempting to maintain,

adjust or service allow such parts to cool.

If unit starts to vibrate abnormally, disengage Main

Clutch, stop engine, remove wire from spark plug and

check immediately for cause. Abnormal vibration is a

warning of trouble. Repair any damage before

restarting unit.

Disengage Main Clutch, stop engine, remove wire

from spark plug and inspect for damage after striking

a foreign object. Repair any damage before

restarting and operating tiller.

DO NOT overload tiller capacity by attempting to till

too deep as too fast a rate.

Tines contacting hard objects will cause rear of tiller

to lurch. If this occurs, let go of the handlebars and

do not restrain the unit. Never attempt to force tines

by hanging on handlebars. Let the machine do the

work - you control the machine.

NEVER operate tiller at high transport speeds on

slippery surfaces. Look behind and use care when

backing.

Take all possible precautions when leaving tiller

unattended; such as disengaging main and tine

clutch, stopping engine, removing wire from spark

plug and keeping wire away from plug to prevent

accidental starting or unauthorized use.

Maintenance and Storage

DO NOT change governor setting or overspeed

engine.

Keep tiller in good operating condition. Keep all

safety devices in place and functioning properly.

Ensure main clutch controls are functioning properly.

Wheels and tines must stop rotating when main

clutch levers are released.

Keep all nuts, bolts, and screws tight and be sure

equipment is in safe operating condition. Check

hardware and tiller at frequent regular intervals.

To reduce fire hazard and overheating, keep

equipment free of debris.

Never store tiller with gasoline in tank inside a

building where ignition sources are present such as

hot water and space heaters, clothes dryers, open

flame or spark, etc. Allow engine to cool before

storing in any enclosure.

Always refer to Owner’s Manual for important details