GB - 4

4. Review recommended lubrication, maintenance

and adjustments.

5. Review Limited Warranty Policy.

6. Fill out Original Purchaser Registration Card and

return the card to Ariens Company.

SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

The safety alert symbols above and signal words below

are used on decals and in this manual.

Read and understand all safety messages.

NOTATIONS

NOTE:

General reference information for proper

operation and maintenance practices.

IMPORTANT:

Specific procedures or information

required to prevent damage to unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area. Always follow the practices

set forth in this manual.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation by the seller. If unit

is to be used by someone other than original

purchaser; loaned, rented or sold, ALWAYS provide

this manual and any needed safety training before

operation.

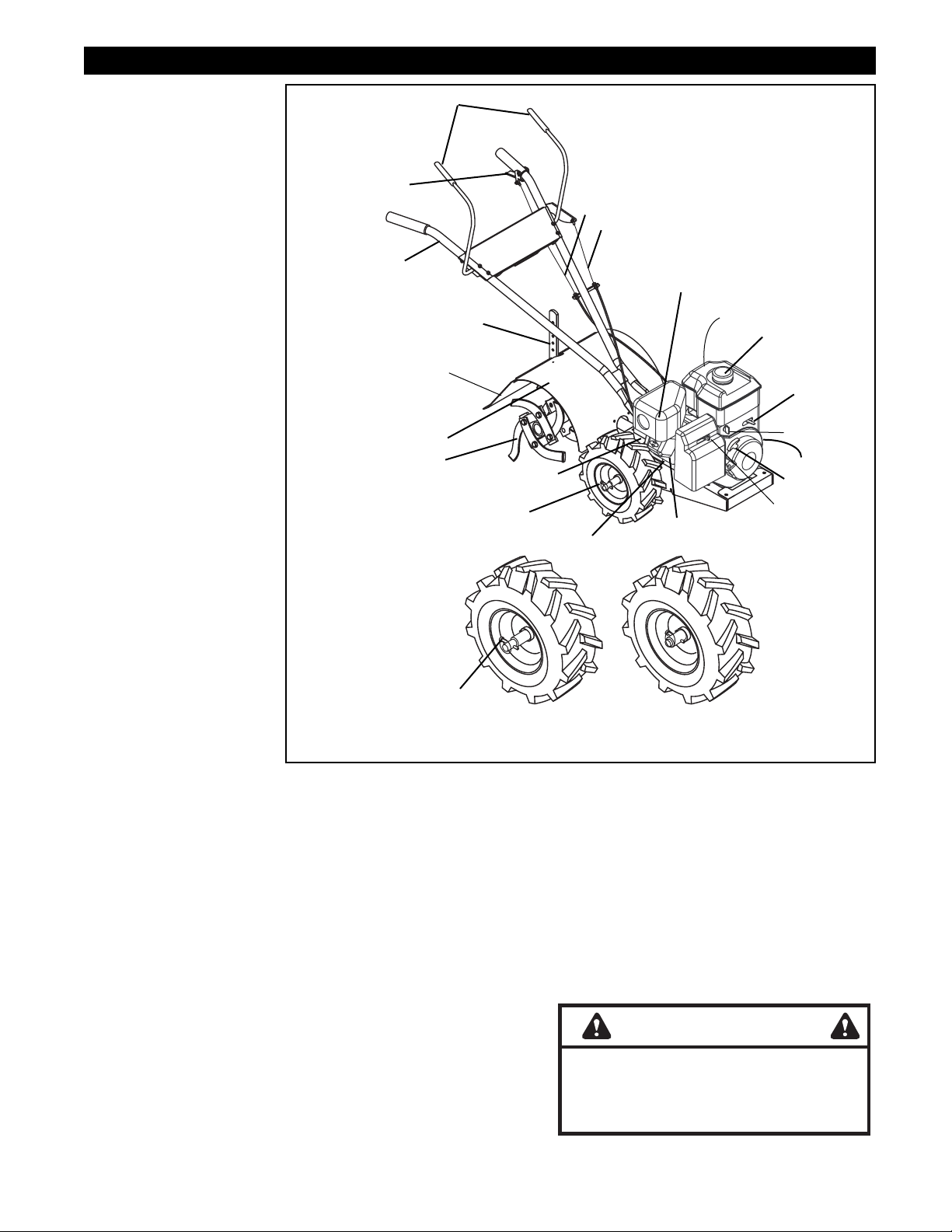

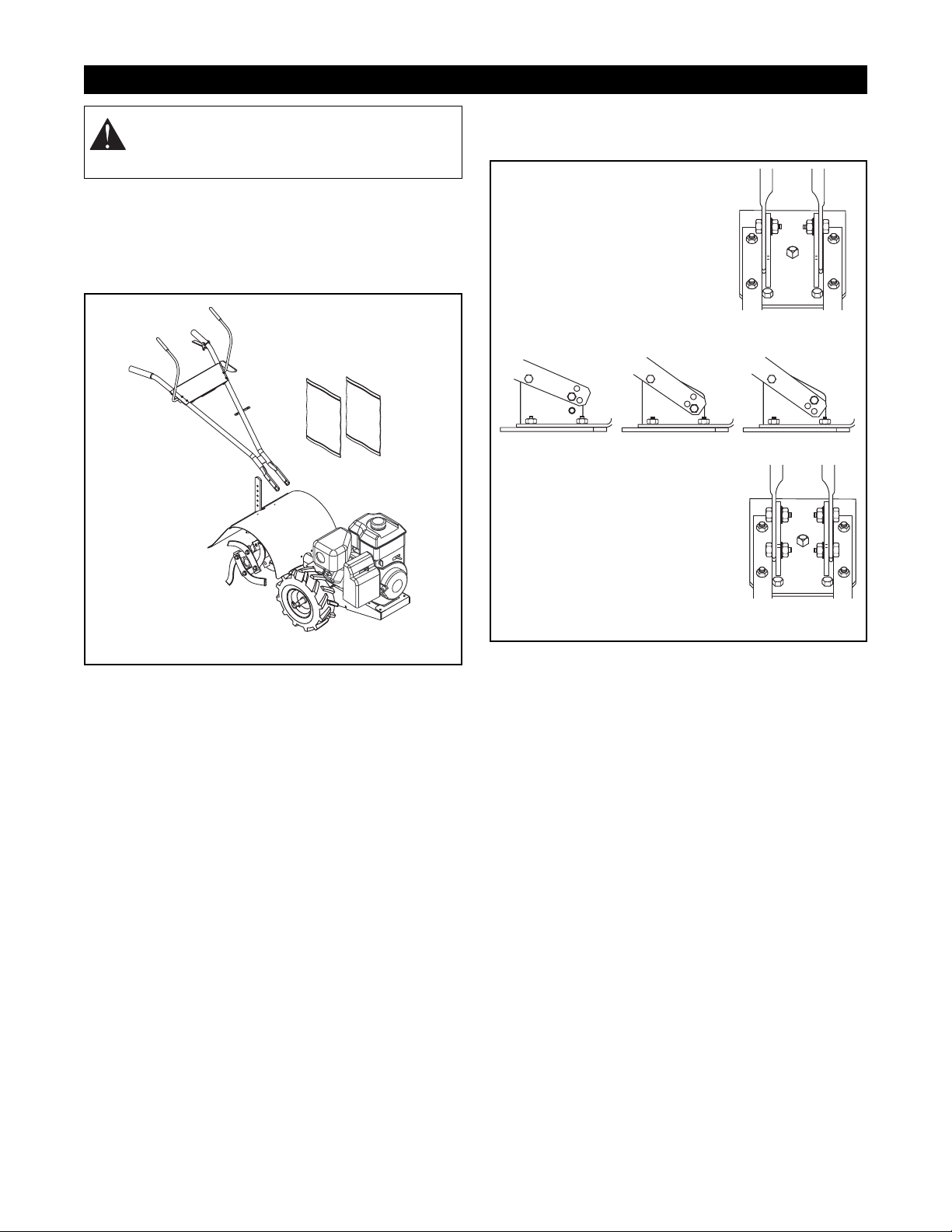

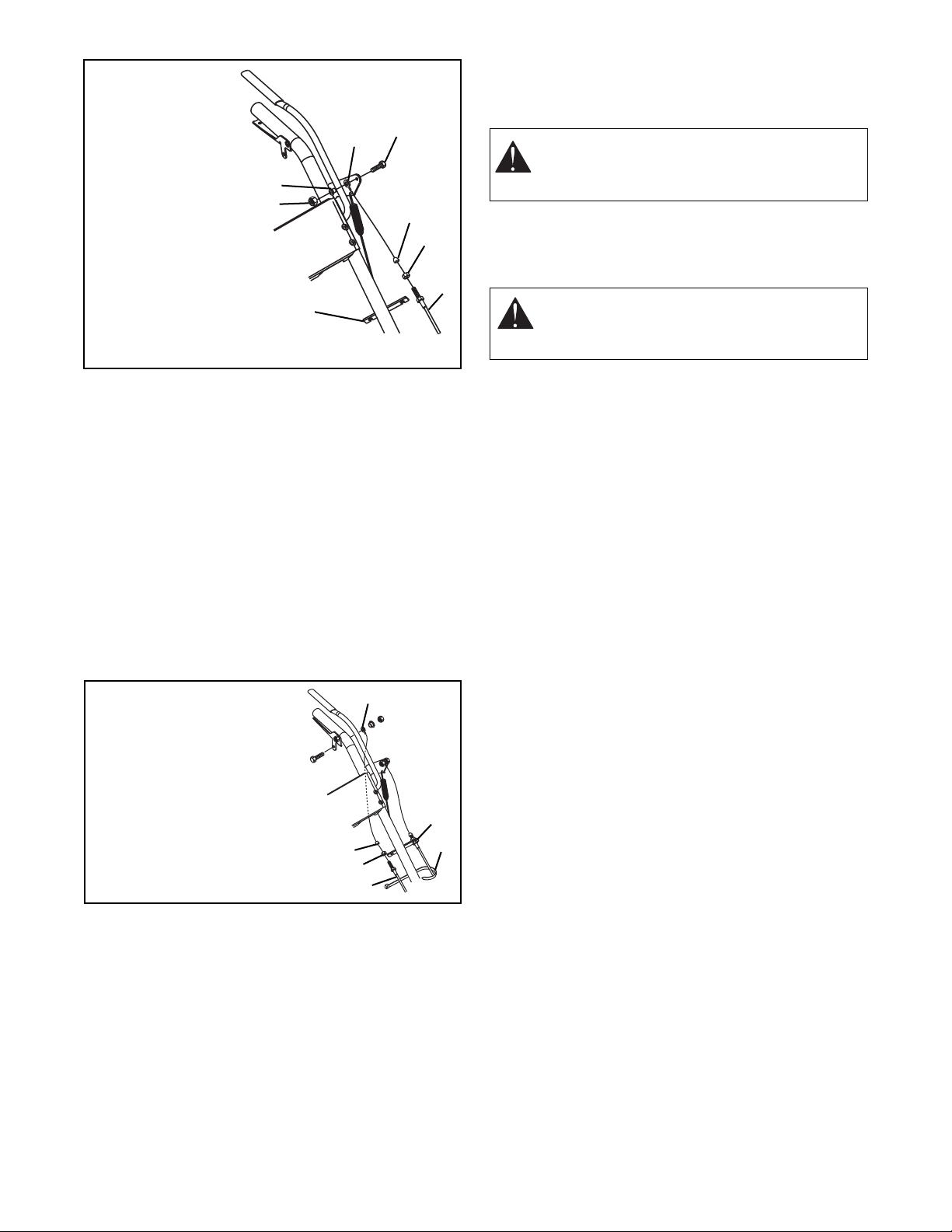

SAFETY DECALS AND LOCATIONS

ALWAYS replace missing or damaged Safety Decals.

Refer to figure below for Safety Decal locations.

1.

WARNING!

Before operating unit, completely read and

understand all manuals provided.

Keep all safety devices and shields in place.

Never allow children or uninstructed adults to

operate machine.

Stop engine and remove spark plug wire

before clearing tines or repairing.

Keep children and others away from unit while

operating.

SAFETY

DANGER:

IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING:

POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD RESULT

in death or serious injury.

CAUTION:

POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

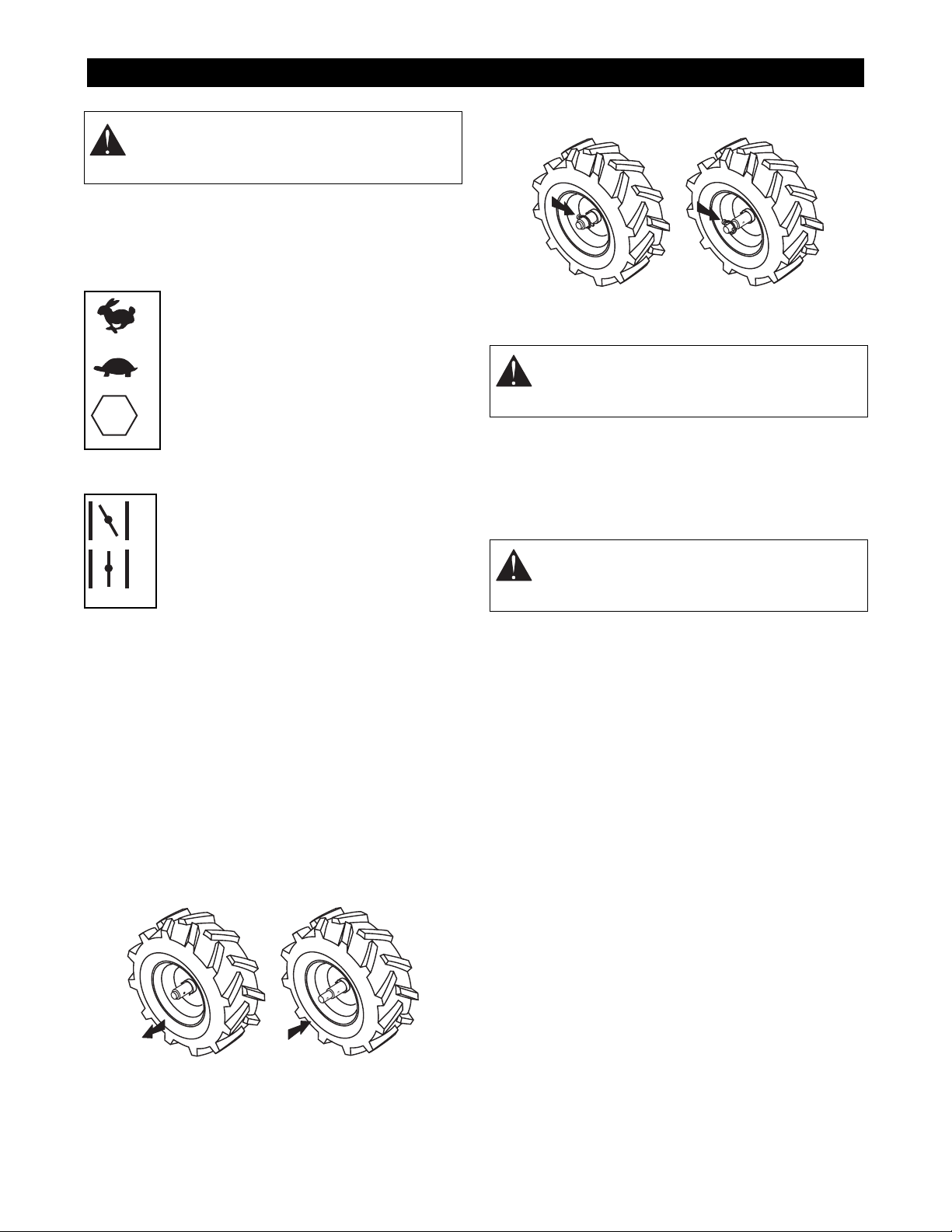

CAUTION

PRUDENCE

080831

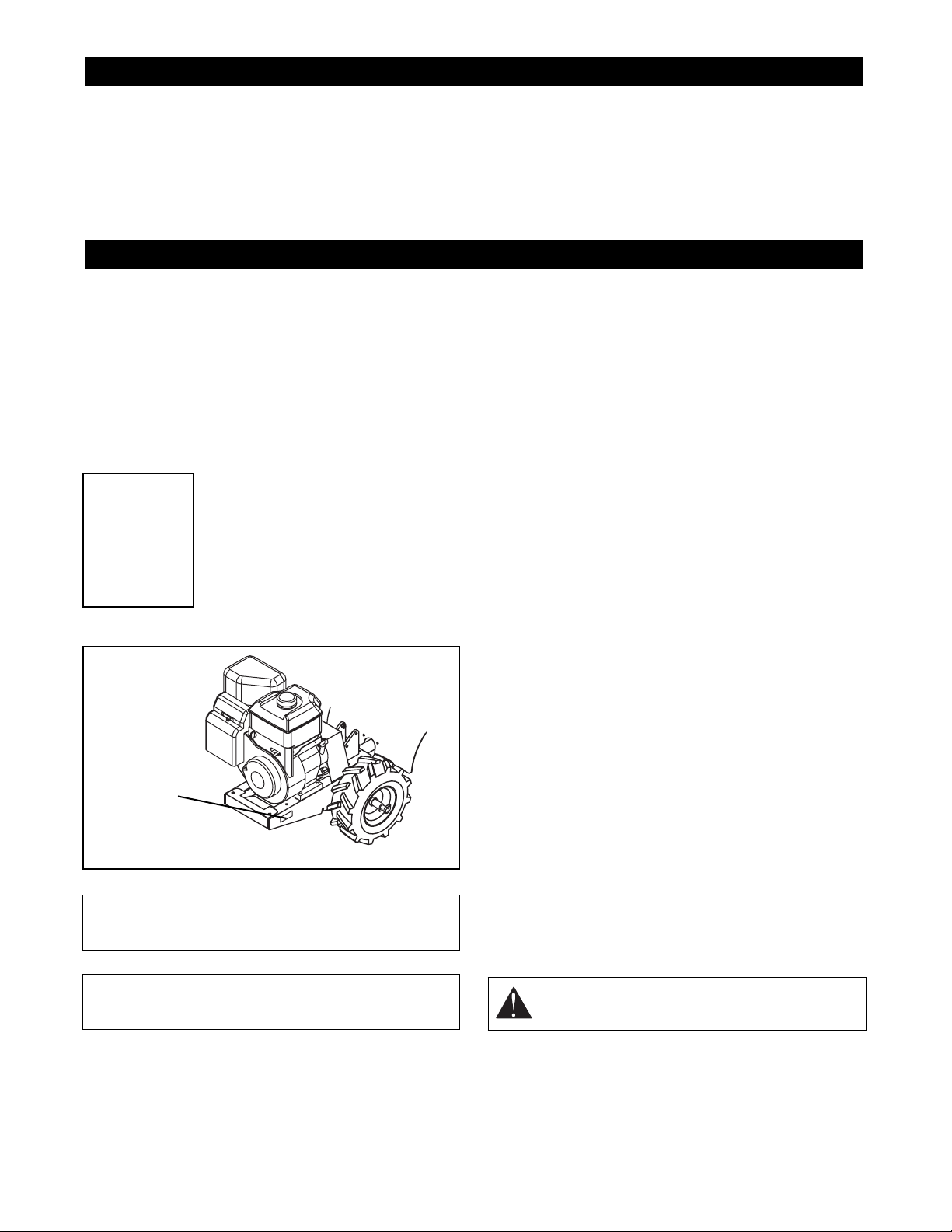

When starting engine

•Make sure clutch is in neutral and

axle drive pins are engaged in wheel

hubs.

•Place feet firmly on the ground and

keep free hand clear of machine.

En démarrant le moteur

•S'assurer que l'embrayage est libre

et que les goupilles d'entraînement

de l'essieu sont engagées dans les

moyeux des roues.

•Se mettre en position stable et dégager

la main de libre de la machine.

CUIDADO

Al arrancar el motor

•Asegúrese que el embrague estéen

neutro y que los dedos de arrastre

del eje impulsor estén enganchados

a los bujes de la rueda.

•Coloque los pies firmemente sobre el

suelo y mantenga su mano libre

alejada de la máquina.

CAUTION

PRUDENCE

CUIDADO

Drive system may

be hot.

080830

Le système

d'entraînement peut

être chaud.

El sistema conductor

puede estar caliente.

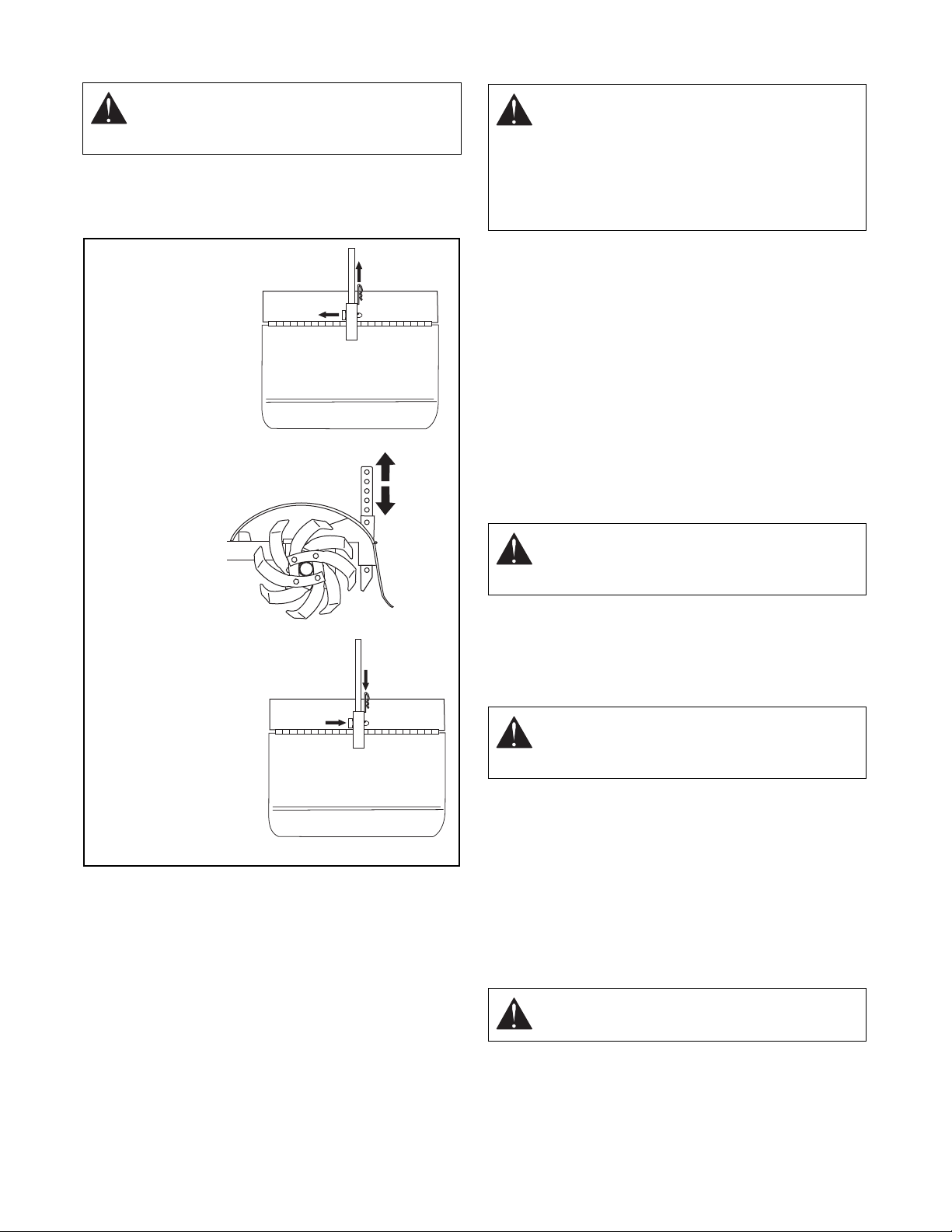

077541

DANGER

ROTATING TINES

• Keep hands and feet away.

• Disengage clutch, stop engine and

remove spark plug wire before

clearing.

ROTATION DES DENTS

• Éloigner les mains et les pieds.

• Débrayer, arrêter le moteur et retirer le

câble de la bougie avant dégagement.

ROTACIÓN DE LOS DIENTES

• Mantenga las manos y los pies alejados.

• Desenganche el embrague, pare el motor

y retire el alambre de la bujía de encendido

antes de limpiarlos.

PELIGRO

DANGER

TO AVOID SERIOUS INJURY

• Before operating unit, completely read

and understand all manuals provided.

• Keep all safety devices and shields in

place.

• Never allow children or uninstructed

adults to operate machine.

• Stop engine and remove spark plug

wire before clearing tines or repairing.

• Keep children and others away from

unit while operating.

• Use extreme caution when reversing or

pulling tiller toward you.

• Know location and function of all

controls.

• Do not operate tines with wheel hub

drive pins disengaged. Loss of control

may result.

• Stop engine when travelling between

work areas.

WARNING

POUR ÉVITER LES BLESSURES GRAVES

• Avant de mettre l'appareil en marche, lire entièrement

et bien comprendre tous les manuels fournis.

• S’assurer que tous les garants et autres dispositifs

de sécurité sont en place et fonctionnent correctement.

• Ne jamais autoriser des enfants ou des adultes non

conpétents à utiliser la machine.

• Arrêter le moteur et retirer le câble de la bougie avant

de dégager les dents ou avant réparation.

• Éloigner les enfants et toute autre personne pendant

le fonctionnement de la machine.

• Êrte extrêmement prudent en faisant marche arrière

ou en tirant la machine vers soi.

• Se familiariser avel l’émplacement et la fonction de

toutes les commandes.

• Ne pas faire fonctionner les dents avec les goupilles

activant le moyeu des roues non engagées, ceci

pourrait entraîner une perte de contrôle.

• Arrêter le moteur pendant le déplacement d'un point

de travail à l'autre.

PARA EVITAR LESIONES GRAVES

• Antes de operar la unidad, lea y comprenda

totalmente todos los manuales provistos.

• Mantener todos los dispositivos de securidad y

protectores colocados y funcionando

correctamente.

• No permitir nunca que niños o personas ajenas

operen la máquina.

• Pare el motor y retire el alambre de la bujía de

encendido antes de limpiar o reparar los dientes.

• Mantenga la unidad alejada de los niños u otras

personas cuando esté en funcionamiento.

• Usar precaución extrema al tirar de o empujar la

máquina.

• Conocer la ubicación y función de todos los

controles.

• No opere los dientes del motocultor con los dedos

de arrastre del buje de la rueda desenganchados.

Esto puede resultar en una pérdida de control.

• Pare el motor al desplazarse entre áreas de trabajo.

ADVERTENCIA

080833

AVERTISSEMENT

1

2

3

4

OB0721

Figure 3

OL1801

OL4630

OL4640

OL4650

OL4370