FEATURES AND CONTROLS

®IGNITION AND STARTER SWITCH —FIGURE 1

The ignition and starter switch has three positions: “OFF",

“RUN", and “START”. Start the engine by turning the key

fully clockwise to “START" position and then release the key as

soon as the engine starts. Stop the engine by turning the key

counterclockwise to the “OFF" position.

®THROTTLE-CHOKE CONTROL LEVER —FIGURE 1

This control operates both the throttle and choke. When starting

acold engine, raise the lever past the offset and into the

"CHOKE” position. After the engine has started, lower the lever

to the throttle operating range and allow the engine to warm at

1/2 throttle. Select the appropriate engine speed in the throttle

range after the engine has warmed up.

NOTE: UNLESS OTHERWISE SPECIFIED, THE ATTACHMENTS

SHOULD BE OPERATED AT FULL THROTTLE. THE THROTTLE IS

NOT TO BE USED TO SELECT DESIRED TRAVEL SPEEDS.

OPERATE AT FULL THROTTLE AND REGULATE GROUND SPEED

WITH THE GEAR SHIFT LEVER.

©LIGHT SWITCH —FIGURE 1

Turn lights on by pulling the control knob out. Turn lights off by

pushing the knob in.

@ATTACHMENT LIFT LEVER —FIGURE 1

To raise the attachment, depress thumb button, pull the lever to

the rear, and release thumb button. This will hold the attachment

in the raised position. When using the mower attachment, select

the “notch" that allows the mower to cut at the desired height.

To lower the attachment, pull the lever to the rear, depress the

button to release the latch and allow the lever to move forward.

©IMPLEMENT POWER CONTROL —FIGURE 1

The Implement Power Control is used to operate the at-

tachments. Push the lever forward to engage the clutch and

drive the attachment. Pull the lever rearward to disengage the

clutch and stop the attachment. The lever must be in the rear

(disengaged) position to start the engine. THIS IS ASAFETY

FEATURE. The engine will not start until the lever has been

placed in the disengaged position.

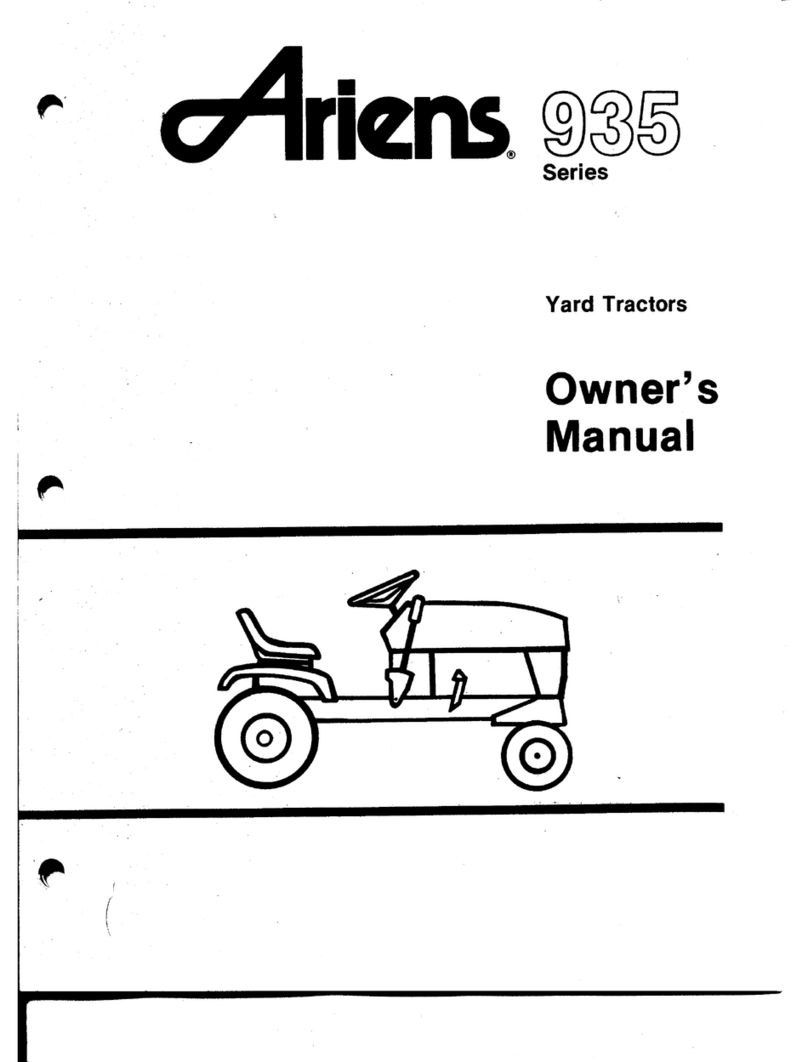

©SPEED SELECTOR LEVER -FIGURE 2

The Speed Selector Lever is used to select any of three forward

gears or one reverse gear. The markings “1, 2, 3“ and "R” on

the floor plate indicate the locations of the gears. The slowest

forward gear is indicated by “1 ", the secondary gear, "2", and

the fastest gear, "3”. The "R" indicates reverse. The Speed

Selector Lever must be in the “NEUTRAL" position as shown in

Figure 2to start the engine. THIS IS ASAFETY FEATURE.

©HIGH-LOW SPEED RANGE SELECTOR -FIGURE 2

The High-Low Speed Selector gives achoice of six forward

speeds; three in “HIGH" range; and three in “LOW" range.

The speed in reverse gear is the same in both ranges.

FIGURE 2

©CLUTCH PEDAL -FIGURE 1

Depressing the Clutch pedal disengages the transaxle from the

engine and permits shifting the speed selector to any desired

gear. Always release the clutch pedal slowly' for smooth ac-

celeration. Do not allow foot to rest on pedal except when

clutching.

IMPORTANT: ALWAYS DEPRESS CLUTCH PEDAL TO EASE

ENGINE STARTING. DEPRESSING CLUTCH PEDAL RELEASES

PARKING BRAKE. BE READY TO APPLY FOOT BRAKE WHEN

STARTING FROM PARK POSITION.

©BRAKE PEDAL —FIGURE 1

Depressing the brake pedal applies pressure to the disk brake

and stops the tractor (with the clutch depressed). Be sure to

depress clutch pedal to disengage the clutch before braking.

Brake will not stop tractor without depressing clutch pedal.

©PARKING BRAKE LOCK -FIGURE 3

AParking Brake Lock is provided to prevent the tractor from

moving when parked or left unattended. To lock the brake, pull

the parking brake lock up with the pedal fully depressed. Then

release the brake pedal. Figure 3shows the parking brake lock

engaged. Clutch pedal must not be depressed when locking

brake. Parking brake lock may be disengaged by depressing

either brake or clutch pedal.

-4-