Form 169216 January 2009

1

MacDon M Series Windrower Tractor

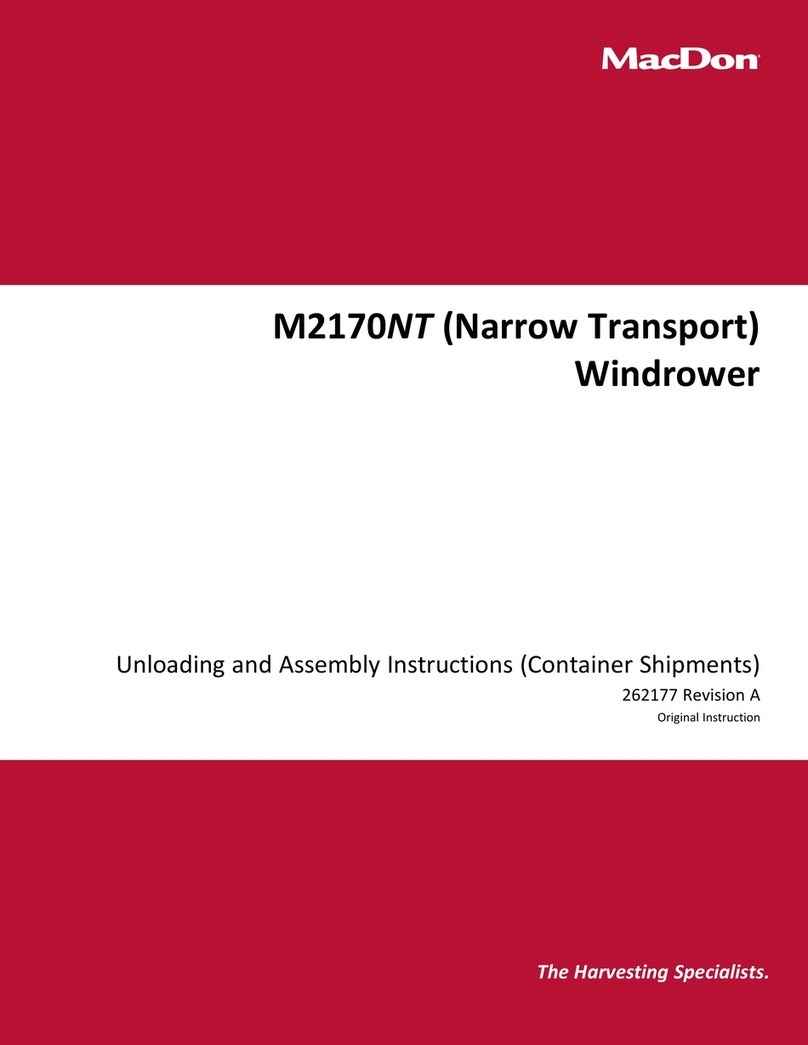

DOUBLE WINDROW ATTACHMENT

TABLE OF CONTENTS

Introduction ............................................................................................................................................. 1

Set-Up Instructions .......................................................................................................................2 - 14

Operation

Safety Sign Locations........................................................................................................................ 14

Safety ................................................................................................................................................ 15

To Raise & Lower Deck..................................................................................................................... 15

Side Delivery Draper Speed.............................................................................................................. 15

Deck Angle ........................................................................................................................................ 16

Deck Height....................................................................................................................................... 17

Conditioner Forming Shield Position................................................................................................. 18

Conditioner Rolls Position ................................................................................................................. 18

Operating Recommendations............................................................................................................ 19

Maintenance/Service

Draper Tension Adjustment............................................................................................................... 20

Draper Tracking Adjustment.............................................................................................................. 20

Draper Replacement ......................................................................................................................... 21

Front Skid Adjustment ....................................................................................................................... 21

Rear Deflector Adjustment ................................................................................................................ 21

Draper Roller Maintenance ......................................................................................................... 22, 23

Lubrication......................................................................................................................................... 23

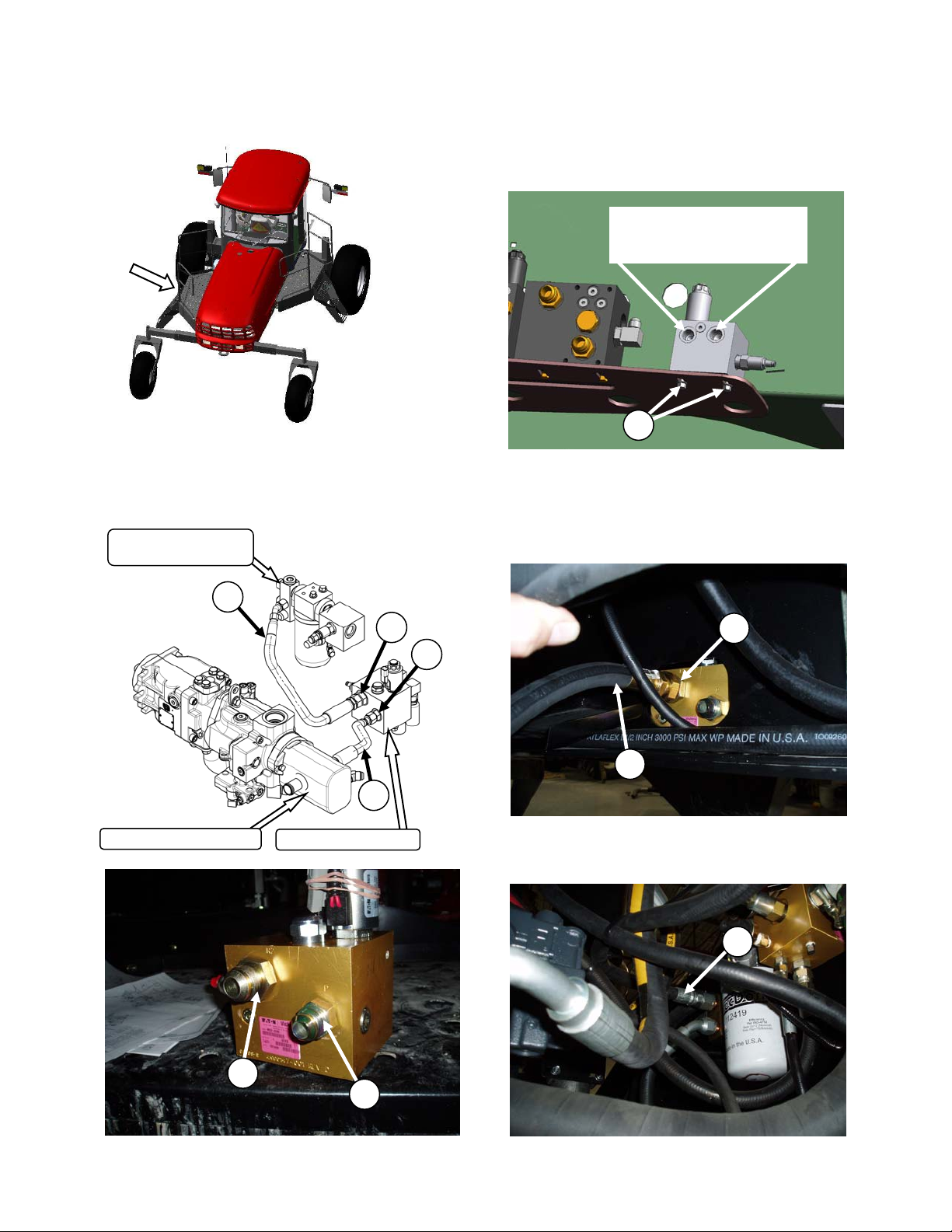

Hydraulic Schematic.......................................................................................................................... 24

Repair Parts........................................................................................................................................... 25

INTRODUCTION

The double windrow attachment (DWA) allows the combining of two windrows of conditioned material

close together to be picked up by a forage chopper. This unit may be mounted on the following MacDon-

built windrower tractors: M150 & M200. The system is for use with Model A30, A40, R80 and D60

headers with HC10 hay conditioners. The conditioned crop is deposited onto the side delivery system

draper and delivered to the side of the tractor when required. Raising the side delivery system shuts off

the draper and allows the crop to be deposited between the tractor wheels as it would be without the side

delivery system.