Contents

Glossary .................................................................................................5

1 General ..................................................................................................6

1.1 Principles ...........................................................................................................6

1.2 Installation of partly completed machinery .................................................... 6

1.3 Target group ..................................................................................................... 6

1.4 Other applicable documents ............................................................................ 6

1.5 Symbols .............................................................................................................6

2 Safety .....................................................................................................7

2.1 Key to safety symbols/markings ....................................................................... 7

2.2 General .............................................................................................................. 7

2.3 Personnel qualification and training ............................................................... 7

2.4 Consequences and risks caused by non-compliance with these operating

instructions ........................................................................................................ 8

2.5 Safety awareness ..............................................................................................8

2.6 Safety instructions for the operator/user ........................................................ 8

2.7 Safety instructions for maintenance, inspection and installation work ....... 8

2.8 Unauthorised modes of operation .................................................................. 9

2.9 Intended use .....................................................................................................9

3 Transport/Temporary Storage/Disposal .............................................10

3.1 Checking the condition upon delivery .......................................................... 10

3.2 Transport ......................................................................................................... 10

3.3 Storage/Preservation ...................................................................................... 10

3.4 Return to supplier ........................................................................................... 10

3.5 Disposal ...........................................................................................................11

4 Description ..........................................................................................12

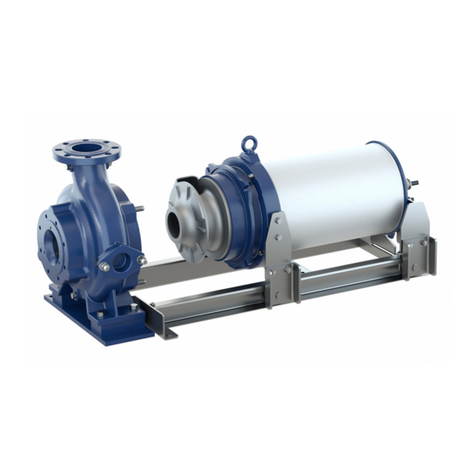

4.1 General description ........................................................................................ 12

4.2 Designation ..................................................................................................... 12

4.3 Name plate ...................................................................................................... 12

4.4 Design details .................................................................................................. 12

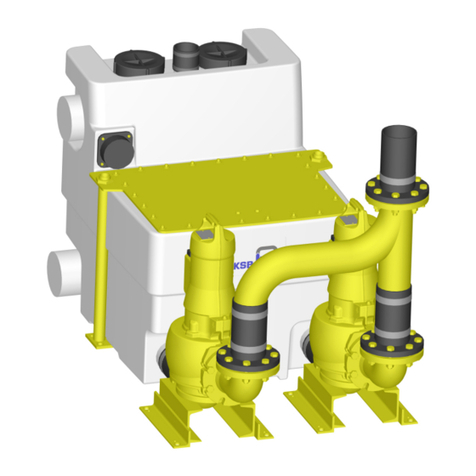

4.5 Configuration and function ........................................................................... 14

4.6 Scope of supply ............................................................................................... 15

4.7 Dimensions and weights ................................................................................16

5 Installation at Site ...............................................................................17

5.1 Safety regulations ........................................................................................... 17

5.2 Checks to be carried out prior to installation ............................................... 17

5.3 Preparing the collecting tank ........................................................................18

5.4 Connecting the piping ...................................................................................21

5.5 Installing the pump(s) and pipe(s) in the collecting tank ............................ 31

5.6 Fitting the cover ............................................................................................. 38

Contents

Evamatic-Box N 3 of 60