List of Contents

1. Introduction..................................................................................................................................................................... 4

1.1. Operating Principle 4

1.2. Applications 4

1.3. Safety Instructions 4

1.4. Unpacking the flowmeter 4

2. Installation....................................................................................................................................................................... 5

2.1. Remote or Compact 5

2.2. Sensor installation 5

2.3. Dry liner 6

2.4. Installation of the transmitter 7

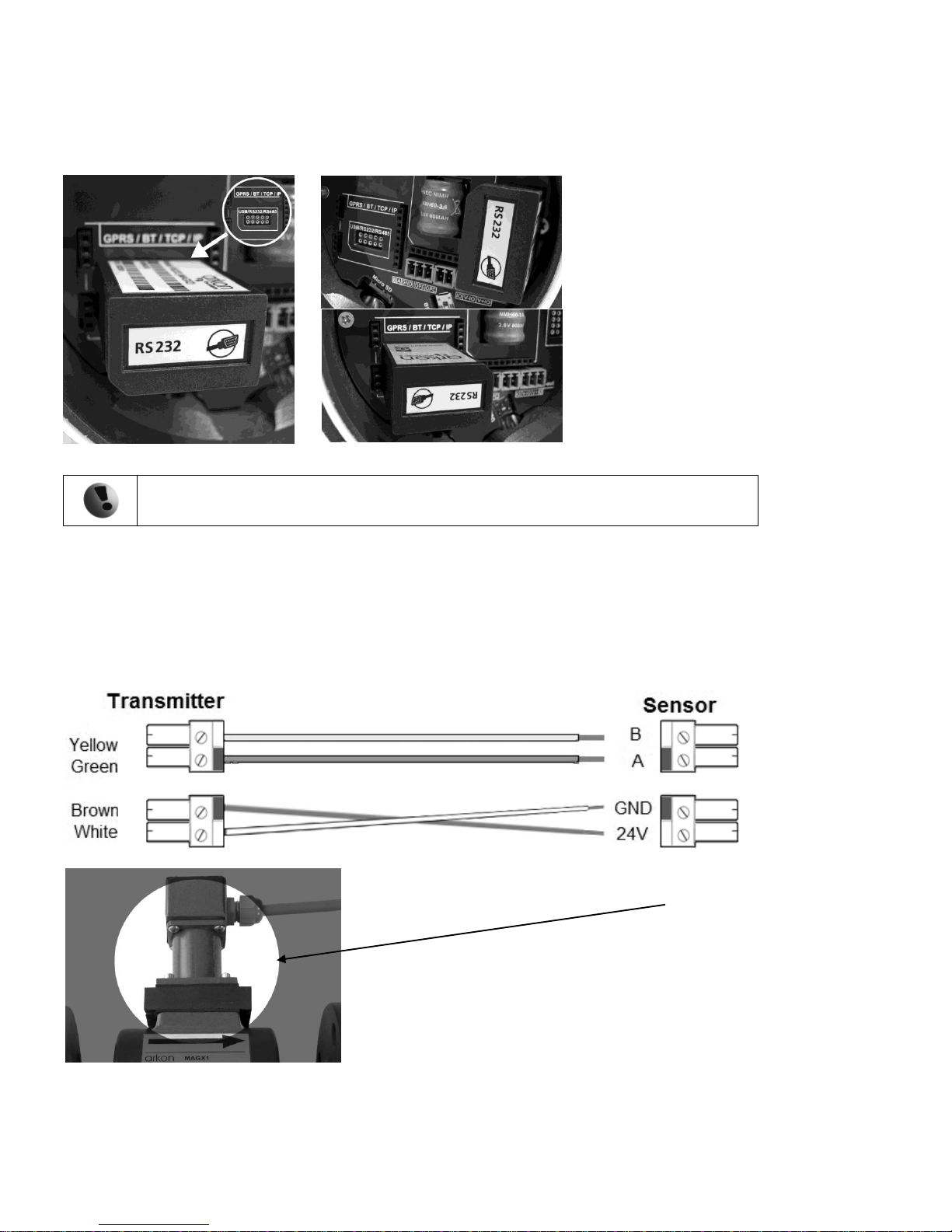

2.5. Module installation 8

2.6. Cables connections 9

2.7. Potting the remote sensor terminal box for sensor communication module 11

2.8. Fill up of a cable gland of MAGX2 IP68 housing 12

2.9. Ambient conditions 12

3. MAGX2 Transmitter Unit............................................................................................................................................ 13

3.1. Main screen 13

3.2. Flowmeter Menu 16

3.3. Info menu 16

3.4. Display menu 17

3.4.1. Display > Unit Flow..................................................................................................................................... 17

3.4.2. Display > Unit Volume ................................................................................................................................ 17

3.4.3. Display > Unit Temperature......................................................................................................................... 17

3.4.4. Display > Unit Pressure................................................................................................................................ 17

3.4.5. Display > Language...................................................................................................................................... 18

3.4.6. Display > Contrast........................................................................................................................................ 18

3.4.7. Display > Backlight...................................................................................................................................... 18

3.5. User Settings Menu 18

3.5.1. User Settings > Measurement....................................................................................................................... 18

3.5.2. User Settings > Datalogger Interval ............................................................................................................. 19

3.5.3. User Settings > CSV Format........................................................................................................................ 19

3.5.4. User Settings > Air Detector ........................................................................................................................ 19

3.5.5. User Settings > Air Constant........................................................................................................................ 19

3.5.6. User Settings > Delete Auxiliary Volume.................................................................................................... 20

3.5.7. User Settings > Start Delay .......................................................................................................................... 20

3.5.8. User Settings > Samples per Avg................................................................................................................. 20

3.5.9. User Settings > Low Flow Cut-off............................................................................................................... 20

3.5.10.User Settings > Flow Qn .............................................................................................................................. 20

3.5.11.User Settings > Invert Flow.......................................................................................................................... 20

3.5.12.User Settings > Current Loop....................................................................................................................... 21

3.5.13.User Settings > Pulse Output........................................................................................................................ 22

3.5.14.User Settings > Frequency output ................................................................................................................ 25

3.5.15.User Settings > Load Default Settings ......................................................................................................... 26

3.5.16.User Settings > Date Setting......................................................................................................................... 26

3.5.17.User Settings > Time Setting........................................................................................................................ 26

3.5.18.User Settings > Password Setup................................................................................................................... 26

3.5.19.User Settings > Modbus ............................................................................................................................... 26

3.5.20.User Settings > Electrode Cleaning.............................................................................................................. 27

3.5.21.User Settings > Totalizer Cycling ................................................................................................................ 28

3.5.22.User Settings > GSM Settings...................................................................................................................... 28

3.5.23.User Settings > Wi-Fi AP mode................................................................................................................... 29