Electromagnetic Flowmeter M-910

2 Operation manual

1Basic information _______________________________________________________ 4

1.1

Basic features _______________________________________________________________4

1.2

Standards and approvals_______________________________________________________4

1.3

Warranty ___________________________________________________________________5

2Preparing for start up ____________________________________________________ 6

2.1

Inspecting contents of the package ______________________________________________6

2.2

Fuse replacement ____________________________________________________________6

2.3

Power supply ________________________________________________________________7

3Installation ____________________________________________________________ 8

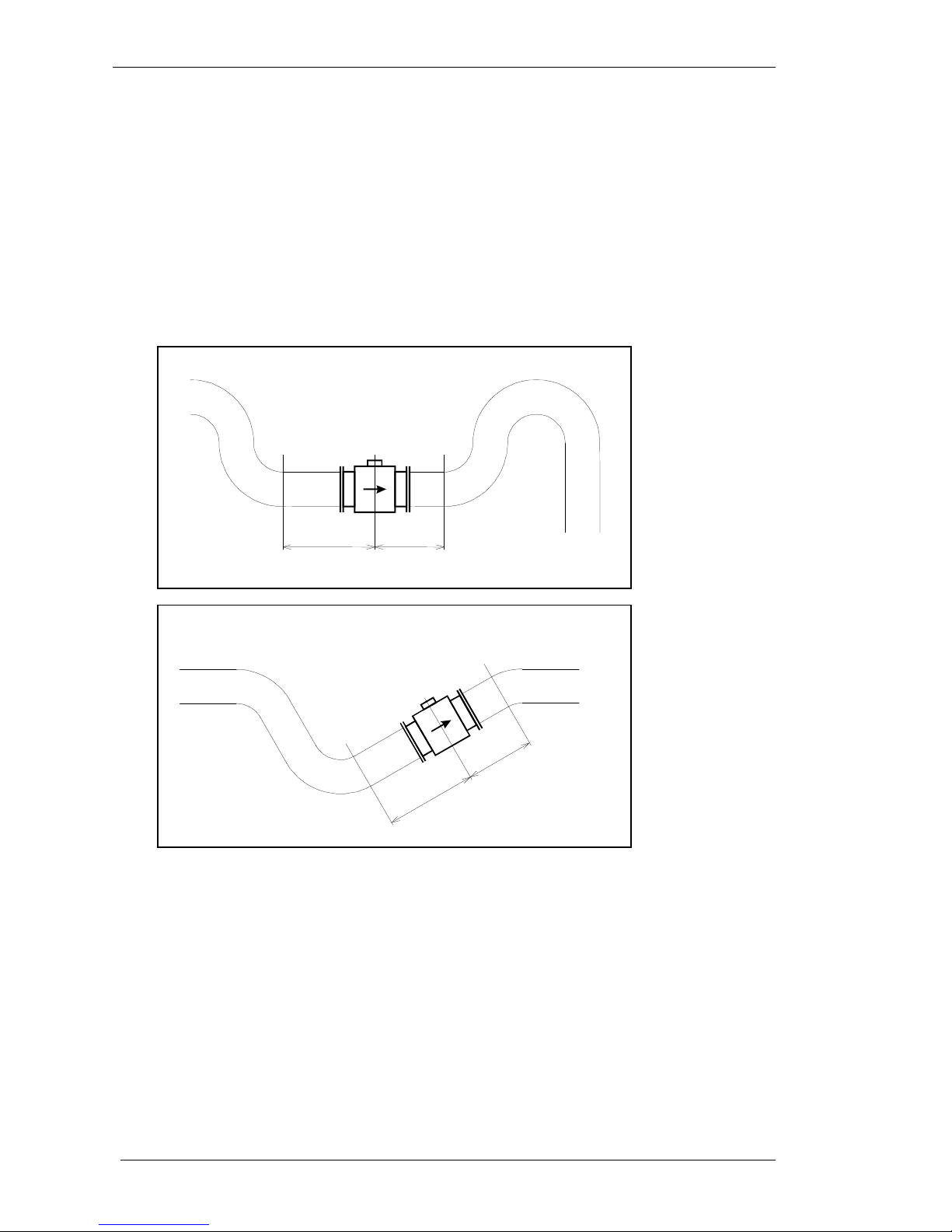

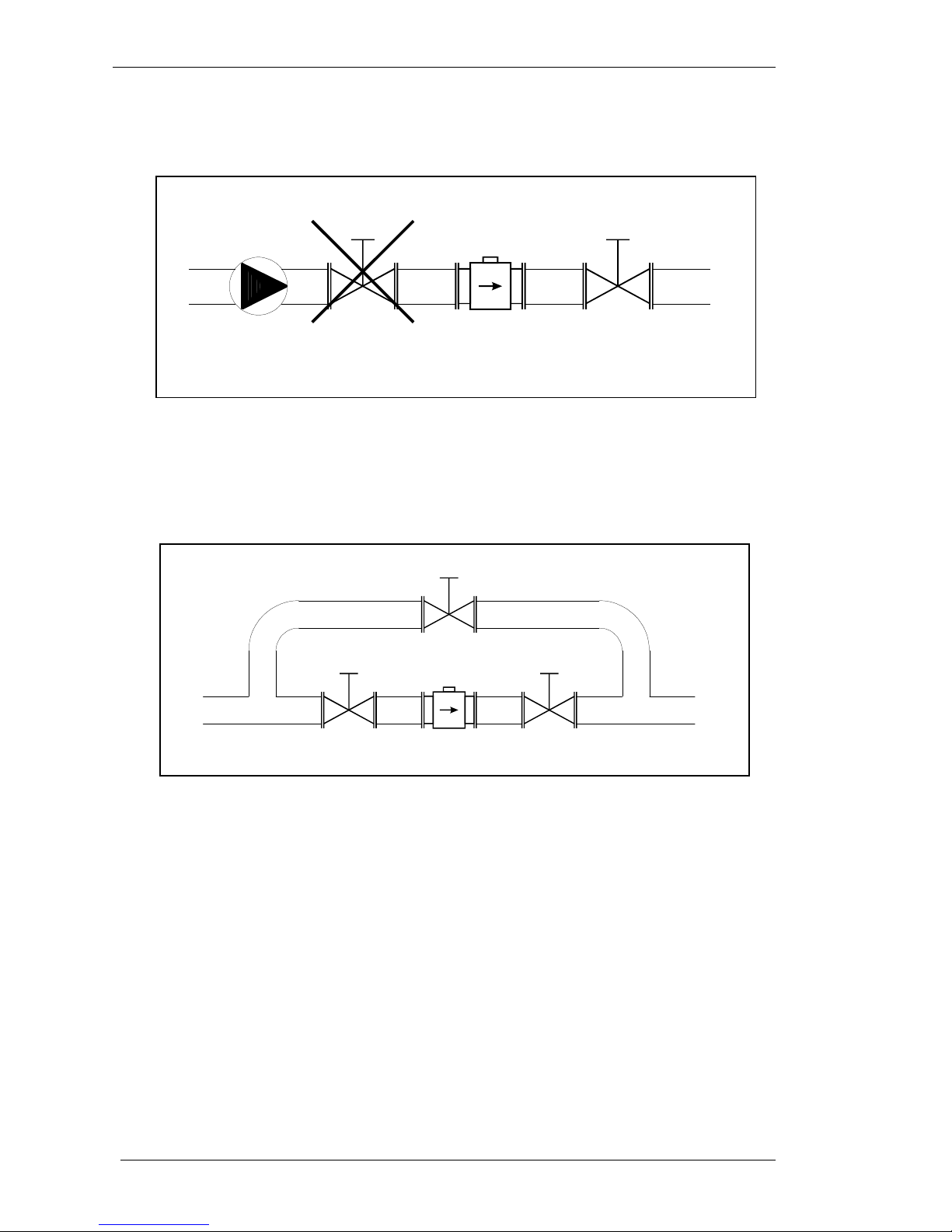

3.1

Sensor location ______________________________________________________________8

3.2

Electrical connection ________________________________________________________11

3.2.1

Compact version ______________________________________________________________ 11

3.3

Sensor grounding ___________________________________________________________12

3.4

Turning the display panel _____________________________________________________12

4Electronic unit description _______________________________________________ 13

4.1

Front panel (display)_________________________________________________________13

4.2

Rear panel (inputs/outputs) ___________________________________________________14

4.3

Signal terminals ____________________________________________________________15

4.3.1

Current loop output____________________________________________________________ 15

4.3.2

Frequency output______________________________________________________________ 16

4.3.3

Impulse output ________________________________________________________________ 16

4.3.4

Status output _________________________________________________________________ 17

4.3.5

PLC digital input ______________________________________________________________ 17

4.3.6

Serial port RS485______________________________________________________________ 17

4.4

Serial port RS232 ___________________________________________________________19

5Operation_____________________________________________________________ 20

5.1

Main menu ________________________________________________________________20

5.1.1

Current Flowrate / Total Volume_________________________________________________ 20

5.1.2

Positive Volume _______________________________________________________________ 20

5.1.3

Negative Volume ______________________________________________________________ 20

5.1.4

Auxiliary Volume______________________________________________________________ 20

5.1.5

Maximum Flowrate / Maximum Flowrate Time_____________________________________ 20

5.1.6

Minimum Flowrate / Minimum Flowrate Time _____________________________________ 20

5.1.7

Datalogger ___________________________________________________________________ 21

5.2

Setup menu ________________________________________________________________21

5.2.1

Input and outputs configuration (1 INPUT/OUTPUT) _______________________________ 21

5.2.1.1

Current loop output (1.1 CURRENT)___________________________________________ 21

5.2.1.2

Frequency output (1.2 OUTPUT F) ____________________________________________ 22

5.2.1.3

Impulse output (1.3 OUTPUT P) ______________________________________________ 23

5.2.1.4

Pulse width (1.4 PULSE WIDTH)______________________________________________ 24

5.2.1.5

Status output (1.5 OUTPUT S)________________________________________________ 24

5.2.1.6

PLC digital input (1.6 INPUT) ________________________________________________ 25

5.2.1.7

Low flowrate limit (1.7 LIMIT PF1) ___________________________________________ 26

5.2.1.8

High flowrate limit (1.8 LIMIT PF2) ___________________________________________ 26

5.2.1.9

Hysteresis of flowrate limits (1.9 HYSTERESIS) _________________________________ 26

5.2.1.10

RS485 baud rate (1.A RS485 B.R.) ____________________________________________ 26

5.2.1.11

RS485 address (1.B RS485 ADDR.) ___________________________________________ 27

5.2.2

Flowmeter configuration (2 FLOWMETER) _______________________________________ 27

5.2.2.1

Flowrate units (2.1 FLOW UNIT) _____________________________________________ 27

5.2.2.2

Flowrate resolution (2.2 FLOW RESOL.) _______________________________________ 27

5.2.2.3

Volume units (2.3 VOLUME UNIT) ___________________________________________ 28