N63 N63TU DOWNPIPES INSTALLATION GUIDE

TOOLS: 6mm Socket, 8mm Socket, 11mm Socket, 13mm Deep Socket, 15mm Deep Socket

O2 Sensor Socket, 6mm Hex Socket/Allen Key, E8 External Torx, E10 External Torx

12" Extension and Swivel Adapter, Adustable Wrench, Flathead Screwdriver, T30 Torx Bit

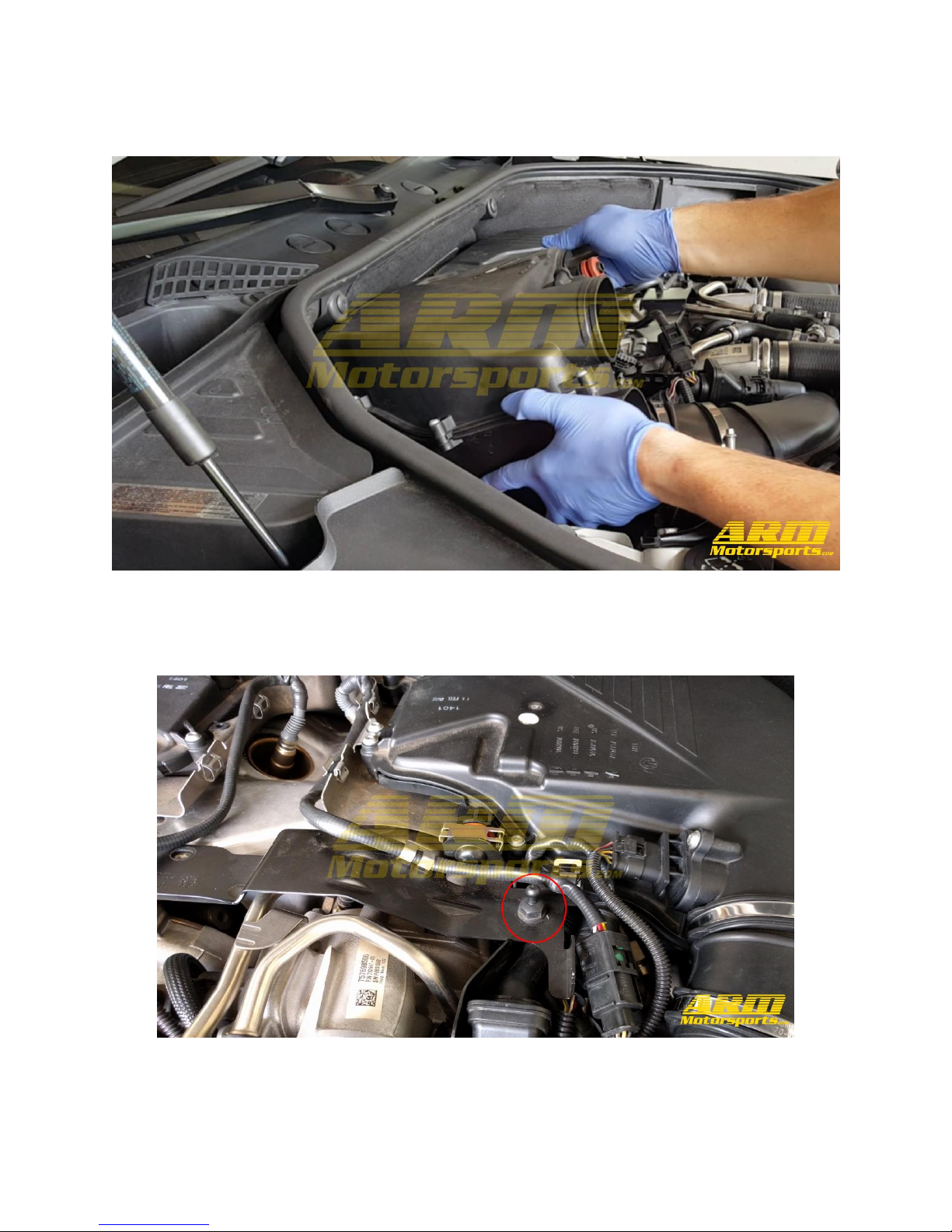

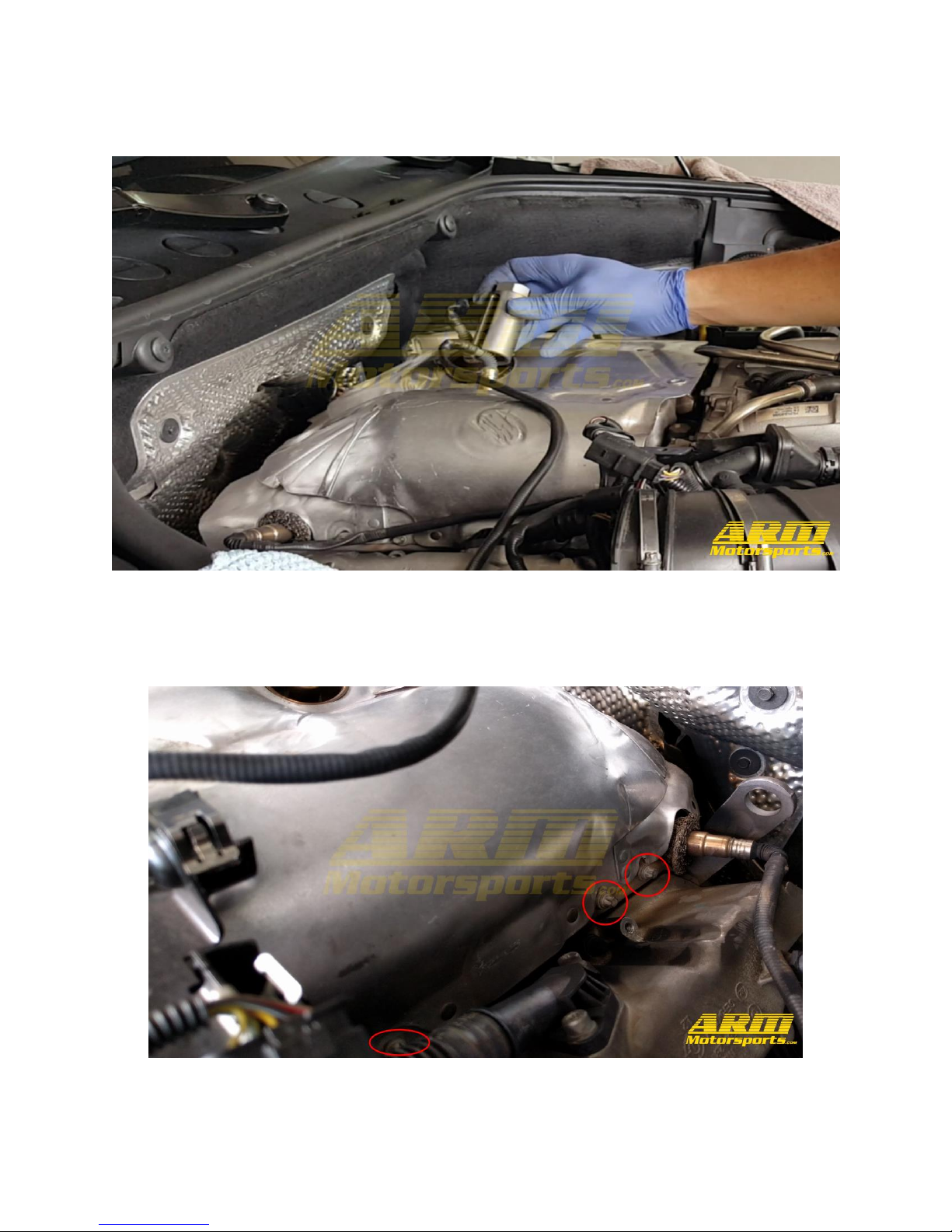

PHASE 1: REMOVE INTAKE

For those of you lifting the vehicle the old fashioned way this installation will only require the front end

of the car to be lifted off of the ground. That said, never work on a car being supported only by a jack.

Always utilize jack stands that meet the weight requirements of your vehicle.