Armstrong Monitoring AMC-1222 User manual

1222

CO/NO2

Multidrop

INSTRUCTIONS

Installation and Operation of the

AMC-1222 Dual Electrochemical Sensor

Module with Comfort Zone

IMPORTANT:

Please read these installation and operating instructions completely

and carefully before starting.

File name:3571405A Copyright ©, Aug 2018

The Armstrong Monitoring Corporation

215 Colonnade Road South, Ottawa, Ontario, Canada K2E 7K3

Tel: (613) 225-9531 • Fax: (613) 225-6965 • Canada & U.S. Toll Free: (800) 465-5777

AMC-1222 CO/NO

2

Multidrop

1

TABLE OF CONTENTS

Section Title Page

1WARRANTY..........................................................................................................................3

1.1LIABILITY.......................................................................................................................3

1.2MODIFICATIONS AND SUBSTITUTIONS.....................................................................3

1.3PRODUCT RETURN......................................................................................................3

2PRODUCT INFORMATION...................................................................................................4

2.1Sensor module ...............................................................................................................5

2.2Factory Calibration AMC1222 1/ 2 variants....................................................................5

2.3Factory Calibration AMC-1222-3....................................................................................6

3PRODUCT DESCRIPTION ...................................................................................................7

3.1GENERAL DESCRIPTION.............................................................................................7

3.1.1Internal Features.....................................................................................................7

4INSTALLATION ..................................................................................................................10

4.1LOCATION AND MOUNTING......................................................................................10

4.2CABLE SELECTION AND WIRING .............................................................................13

4.2.1Multi-Unit Interconnection......................................................................................13

4.2.2TERMINATION......................................................................................................13

5OPERATION AND CALIBRATION.....................................................................................15

5.1OPERATION ................................................................................................................15

5.1.1LOW AND HIGH ALARM CONDITIONS...............................................................15

5.1.2COMFORT ZONE.................................................................................................15

5.2CALIBRATION..............................................................................................................16

5.2.1Zero Adjustment (CO)...........................................................................................16

5.2.2Span Adjustment for (CO) 100 PPM (AMC1222-1 and -2 variants)......................16

5.2.3Span Adjustment for (CO) 75 PPM (AMC-1222-3) ...............................................17

5.2.4Zero Adjustment (NO

2

)..........................................................................................18

5.2.5Span Adjustment (NO

2

).........................................................................................18

MAINTENANCE .........................................................................................................................20

5.3GENERAL ....................................................................................................................20

5.4VERIFICATION OF OPERATION ................................................................................20

5.5SENSOR REPLACEMENT ..........................................................................................20

Figure 2-1 AMC-1222 Sensor Module..........................................................................................4

Figure 3-1 Internal Features of the AMC-1222 Sensor Module....................................................9

Figure 4-1 Transmitter Mounting Dimensions.............................................................................11

Figure 4-2 Pole Mount ................................................................................................................12

Figure 4-3 Detail wiring of Sensor Modules................................................................................14

Figure 4-4 Typical System Configuration Layout........................................................................14

Figure 5-1 Calibration Procedure for 1222 CO...........................................................................17

Figure 5-2 Calibration Procedure for 1222 NO2.........................................................................19

AMC-1222 CO/NO

2

Multidrop

2

NOTE

This page intentionally left blank

AMC-1222 CO/NO

2

Multidrop

3

1WARRANTY

The AMC-1222 Module is warranted against defects in material and workmanship for a period of

two years from date of shipment (For sensor warranties see section 2.1). During the warranty

period, The Armstrong Monitoring Corporation will repair or replace components that prove to

be defective in the opinion of AMC. We are not liable for auxiliary interfaced equipment, or

consequential damage. This warranty shall not apply to any product, which has been modified

in any way, which has been repaired by any other party other than a qualified technician or

authorized AMC representative, or when such failure is due to misuse or conditions of use.

1.1 LIABILITY

All AMC products must be installed and maintained according to instructions. Only qualified

technicians should install and maintain the equipment. AMC shall have no liability arising from

auxiliary interfaced equipment, for consequential damage, or the installation and operation of

this equipment. AMC shall have no liability for labour or freight costs, or any other costs or

charges in excess of the amount of the invoice for the products.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

AND SPECIFICALLY THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE

DESCRIPTION ON THE FACE THEREOF.

1.2 MODIFICATIONS AND SUBSTITUTIONS

Due to an ongoing development program, AMC reserves the right to substitute components and

change specifications at any time without incurring any obligations.

1.3 PRODUCT RETURN

All products returned for warranty service will be by prepaid freight and they will only be

accepted with a repair number issued by AMC. All products returned to the client will be freight

collect.

WARNING

USING ELECTRICALLY OPERATED EQUIPMENT NEAR GASOLINE, OR GASOLINE

VAPOURS MAY RESULT IN FIRE OR EXPLOSION, CAUSING PERSONAL INJURY AND

PROPERTY DAMAGE. CHECK TO ASSURE THE WORKING AREA IS FREE FROM

SUCH HAZARDS DURING INSTALLATION OR WHEN PERFORMING MAINTENANCE,

AND USE PROPER PRECAUTIONS.

AMC-1222 CO/NO

2

Multidrop

4

2PRODUCT INFORMATION

Figure 2-1 AMC-1222 Sensor Module

AMC-1222 CO/NO

2

Multidrop

5

2.1 Sensor module

Sensor Module Part Number …………………………. AMC 1222

Sensor Module Serial Number ………………………..

CO Sensor Element Part Number .…………………… AMC 91A

CO Sensor Element Serial Number ………………….

CO Sensor Element Warranty Period ………………. year(s)

NO

2

Sensor Element Part Number ….……..………… AMC 98A

NO

2

Sensor Element Serial Number … …………….

NO

2

Sensor Element Warranty Period ……………… year(s)

Power Supply Requirement …………………………... 12 to 24 VDC

Operating Temperature ……………………………….. -20° to 40° C

Operating Pressure ……………………………………. Ambient atmospheric pressure

Relative Humidity ………………………………………. 10 to 95% RH, non-condensing

2.2 Factory Calibration AMC1222 1/ 2 variants

Gas Type ……………………………………... CO NO

2

Low Alarm Setting …………………………… 25 ppm or 35ppm * 1 ppm

High Alarm Setting / Full Scale……… … … 100 ppm 3 ppm

Comfort Zone Alarm ……………………… User Selectable

Sensitivity User Selectable

Sensitivity

Calibration Adapter Part Number………….. N/A N/A

* Variant AMC1222-1 is configured for 35ppm CO Low Alarm Setting, AMC1222-2 is configured

for 25ppm CO Low Alarm Setting.

AMC-1222 CO/NO

2

Multidrop

6

2.3 Factory Calibration AMC-1222-3

Gas Type ……………………………………... CO NO

2

Low Alarm Setting …………………………… 25 ppm 1 ppm

High Alarm Setting / Full Scale……… … … 75 ppm 3 ppm

Comfort Zone Alarm ……………………… User Selectable

Sensitivity User Selectable

Sensitivity

Calibration Adapter Part Number………….. N/A N/A

* Variant AMC1222-3 is configured for 25ppm CO Low Alarm Setting and 75ppm CO High

Alarm Setting.

Note:

All Armstrong Monitoring systems must be installed and maintained according to

instructions, to ensure proper operation. Only qualified technicians should install and

maintain the equipment. Qualified personnel should perform the installation according

to applicable electrical codes, regulations and safety standards. Insure correct cabling

practices are implemented.

AMC-1222 CO/NO

2

Multidrop

7

3PRODUCT DESCRIPTION

In this section a general product description is given followed by a detailed list of the AMC-1222

module's internal features.

3.1 GENERAL DESCRIPTION

The AMC-1222 sensor module provides continuous, reliable surveillance of surrounding air for

traces of hazardous gases (listed in section 2.2 FACTORY CALIBRATION, page 4). This

module is designed to allow interconnection in series as in a "daisy chain" configuration (refer to

Figure 4-3

) to a single or multi-zone AMC 1AD Series monitor or to any other monitor which

can accept voltage or current signal as specified in section 5.1 OPERATION. When using an

AMC 1AD Series monitor, a maximum of eight (8) sensor modules can be connected to each

zone. Each module produces Low alarm, High alarm and Fail signals, which are transferred

from one sensor module up the line of modules to the monitor.

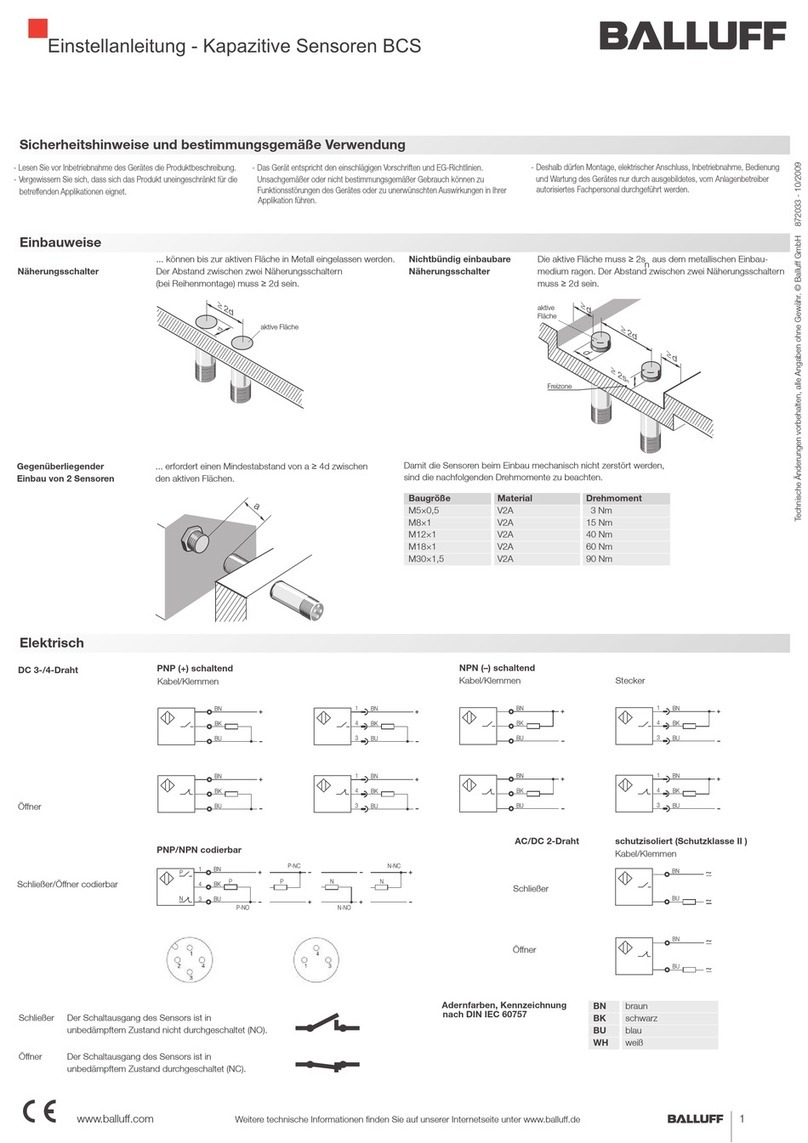

3.1.1 INTERNAL FEATURES

Each sensor module features alarm indicators, adjustment trimmers and connection terminal

blocks, as listed and described below.

1. CO SENSOR: Electrochemical cell, factory calibrated.

2. NO

2

SENSOR: Electrochemical cell, factory calibrated.

3. CO LOW/HIGH ALARM

INDICATOR: Low conditions of CO gas are indicated by a red blinking LED and

High conditions are indicated by a solid red LED.

4. NO

2

LOW/HIGH ALARM

INDICATOR: Low conditions of NO

2

gas are indicated by a red blinking LED

and High conditions are indicated by a solid red LED.

5. COMFORT ZONE

ALARM INDICATOR:

Comfort Zone condition is indicated by an amber LED.

6. POWER/FAIL

INDICATOR: Power is indicated by an illuminated green LED. Fail indicated by

flashing LED.

7. EIGHT POSITION DIP

SWITCH: Each actuator on the DIP switch controls a different circuit as

shown in

Figure 3-1

. If the actuator is set in the RIGHT position,

its corresponding circuit is ON. If the actuator is set in the LEFT

position, the circuit is OFF.

7-1 EOL (end of line) DIP

SWITCH: The EOL is switched on for the last module in a chain and is off

for all others. Refer to section 4.2.2 TERMINATION, for more

details.

7-2 Comfort Zone DIP

SWITCH This Switch is used to enable (ON) or Disable (OFF) the comfort

zone alarm feature. Default setting for this switch is OFF

AMC-1222 CO/NO

2

Multidrop

8

7-3 TD DIP SWITCH: 5 minute alarm output activation time delay for CO sensor only.

7-4 MR DIP SWITCH: Keeps the output signal on the last alarm level on for 5 minutes

longer after the alarm condition has cleared

7-5 DIP SWITCH:

Dip switch positions used to set the comfort zone sensitivity.

SW5(A) SW6(B) SW7(C) SW8(D) Sensitivity

7-6 A DIP SWITCHES:

OFF OFF OFF OFF Super High

7-7 B DIP SWITCHES:

OFF ON OFF ON High

7-8 C DIP SWITCHES:

ON OFF ON OFF Med

7-8 D DIP SWITCHES:

ON ON ON ON Low

8-A CO SPAN SIGNAL

ADJUSTMENT:

Sets the sensitivity of the CO sensor.

8-B NO

2

SPAN SIGNAL

ADJUSTMENT:

Sets the sensitivity of the NO

2

sensor.

8-C NO

2

ZERO SIGNAL

ADJUSTMENT:

Sets the zero NO

2

signal.

8-D CO ZERO SIGNAL

ADJUSTMENT:

Sets the zero CO signal.

9. INPUT The input terminal block is used to connect additional sensor

modules. If input terminal block is not used, EOL is switched ON

10. OUTPUT The output terminal block connects to the monitor or the input

terminal of another module.

11. CURRENT/VOLTAGE

JUMPERS Configure between current or voltage output. Jumpers on “I” for

current output and on “V” for voltage output.

12. NO2 SPAN

CALIBRATION

JUMPER

Configure NO2 calibration gas concentration. Jumper on “A” for

normal and on ”B” for double gas concentration calibration.

AMC-1222 CO/NO

2

Multidrop

9

B

A

+-

-S+

INPUT

OUTPUT

S

1

2

3

4

5

6

7

8

EOL

CZ

TD

MR

A

B

C

D

7.

OFF/ON

2.

3.

4.

5.

6.

8.

9.

10.

11.

12.

1.

Electrochemical

CO Sensor

NO2 Sensor

Electrochemical

NO2 Alarm LED

CO Alarm LED

Reset

Test Header

COM Test Point

ICSP

CO Test Point

NO2 Test Point

Jumper setting for I

Jumper setting for V

JP1

Input

Output

Comfort Zone

Alarm LED

A

A) CO Span

D) CO Zero

C) NO2 Zero

B) NO2 Span

B

Power LED

JP2

Figure 3-1 Internal Features of the AMC-1222 Sensor Module

AMC-1222 CO/NO

2

Multidrop

10

4INSTALLATION

This section relates to the proper installation of the AMC-1222 module. The topics of proper

location, sensor wiring selection, and multi-unit interconnection are all discussed in detail.

4.1 LOCATION AND MOUNTING

Mount the sensor module on a solid, non-vibrating surface or structure, easily accessible for

status checking and calibration. The module must be mounted in an area where the local

concentration of gas is unaffected by the presence of ventilation systems. Mounting height of

modules must be in compliance with local legislations and regulations.

4.1.1 MOUNTING

1. Remove cover and mounting bracket with transmitter.

2. Mount housing using defines mounting holes. See

Figure 4-1

or

Figure 4-2

.

3. Drill holes for conduit and then install conduit. See Warning below.

4. Reattach cover and bracket.

Warning:

Conduit should enter the housing from the bottom to ensure best protection against

ingress of condensation.

Conduit entry from the top from the top of the housing is Not Recommended, and will

Void the Warranty. However, if conduit entry through the top is the only available

option, a Condensation Drip Shield is provided to help protect the electronics from

water ingress due to condensation from the EMT conduit. If conduit entry is through

the top of the housing, a drain hole must be drilled into the bottom side of the housing

to allow the condensation to exit the housing.

Note:

Mounting arrangement of the housing depends on the location and mounting surface.

Mounting hardware is NOT supplied.

AMC-1222 CO/NO

2

Multidrop

11

Figure 4-1 Transmitter Mounting Dimensions

AMC-1222 CO/NO

2

Multidrop

12

Figure 4-2 Pole Mount

AMC-1222 CO/NO

2

Multidrop

13

4.2 CABLE SELECTION AND WIRING

To gain access to the terminal blocks, remove the four (4) screws and front panel from the

housing. This will expose the field wiring terminals. The sensor module output (-,OUT,+)

terminal block, connects to the input (-,IN,+) terminal block of the next module towards the

monitor, or to the sensor/transmitter terminal block in the monitor, as shown in

Figure 4-3

.

Connection should be made using 3-conductor, shielded cable (shield must be grounded at the

monitor). Run cable through steel conduit for best signal transmission and maximum noise

rejection. When using an AMC 1AD Series monitor and with eight (8) modules, a maximum

length of 150 feet of 18 AWG size cable is allowed between each module as well as between

the monitor and first module. For other distances or cable sizes, consult with The Armstrong

Monitoring Corporation.

4.2.1 MULTI-UNIT INTERCONNECTION

Each sensor module is designed to interconnect to other modules in series configuration.

Typical configuration is shown in

Figure 4-4

. Since each module is pre-calibrated, additional

modules can be added to a system without altering the monitor settings. When multiple modules

are interconnected, the EOL switch is in the off position except for the last one (refer to section

4.2.2 TERMINATION and

Figure 4-3

).

4.2.2 TERMINATION

The input terminal block for the last module in the chain will be empty and the EOL (end of line)

DIP switch is switched on.

AMC-1222 CO/NO

2

Multidrop

14

s

s

INPUT

s

s

OUTPUT

MONITOR

Up to 8 1222s can be

Daisy-chained

Max 150ft 18AWG wire

between each module

To next Module

_S+

Figure 4-3 Detail wiring of Sensor Modules

Figure 4-4 Typical System Configuration Layout

AMC-1222 CO/NO

2

Multidrop

15

5OPERATION AND CALIBRATION

This section covers instructions for the proper operation and calibration of the AMC-1222

module. The operation principles are described in further detail, followed by different types of

periodic adjustments that might be required throughout the lifetime of the equipment.

5.1 OPERATION

In general, after the stabilization period and in a clean air environment, the sensor module

should be displaying a GREEN Power ON LED. This green indicator, as well as the two red

alarm indictors and the amber logic indictor, are all visible through windows on the front panel.

Fail is indicated by a flashing power LED.

Input and Output Magnitudes in Various Conditions in Current or Voltage Mode:

Operation condition Voltage Mode Current Mode

Fail 0 VDC 0 mA

Normal 1 VDC 4 mA

Low Alarm 2 VDC 8 mA

High Alarm 3 VDC 12 mA

5.1.1 LOW AND HIGH ALARM CONDITIONS

If any gas exceeds the LOW alarm trip point setting, the red LED will start flashing and the

module will transmit a Low Alarm signal, and when using an AMC 1AD Series monitor, it also

turns ON the yellow LED at the monitor. Likewise, if any gas exceeds the HIGH alarm trip point

setting, the red LED's will turn ON and transmit a High Alarm signal to the monitor.

5.1.2 COMFORT ZONE

The comfort zone alarm condition is user selectable by using four DIP switches; three switches

for CO gas and one for NO

2

gas. When activated the amber LED turns ON and outputs to the

monitor the same as the Low Alarm condition.

SW5(A) SW6(B) SW7(C) SW8(D) Sensitivity

OFF OFF OFF OFF Super High

OFF ON OFF ON High

ON OFF ON OFF Med

ON ON ON ON Low

AMC-1222 CO/NO

2

Multidrop

16

5.2 CALIBRATION

The AMC-1222 sensor module is factory calibrated at levels based on set standards.

Calibration of the module should last for the life of the sensor, with few periodic adjustments. All

on-site adjustments are made at each sensor module. Recalibration is necessary when

replacing the sensor. Factory or on-site calibration services, customer training, and/or

calibration adapter can be provided. Specify each sensor module’s model number and gas

when requesting any of the above. Refer to sections 2.1 Sensor module and/or 2.2 FACTORY

CALIBRATION for any of the above required information.

Notes:

- The calibration procedure is the same whether the module is in current or voltage mode.

Voltage is measured at the test points when the module is in either mode.

Equipment Required:

Digital Multimeter

Miniature slot screw driver

CO and NO

2

Calibration Adapters

Zero & Span gases and regulator (Contact factory for information)

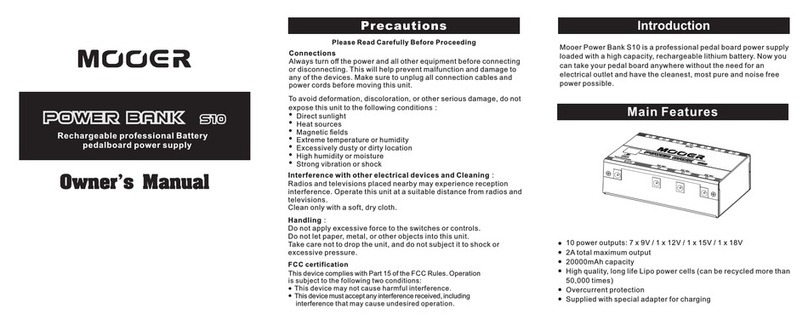

5.2.1 ZERO ADJUSTMENT (CO)

Step 1 Remove cover

Step 2 Power unit from 12-24VDC Supply, Ensure green power LED illuminates. If power LED

is flashing ensure EOL (end of line) Switch(es) are set correctly.

Step 3 Set multimeter to DC voltage range suitable for reading 2.00VDC

Step 4 Connect Multimeter to COM(-) and TP2 as shown in

Figure 5-1

Step 5 Apply Zero gas @ 1L/min

Step 6 After signal reading has stabilized (approx 1 min) adjust Zero Potentiometer to

0.00VDC

Step 7 Remove calibration gas

5.2.2 SPAN ADJUSTMENT FOR (CO) 100 PPM (AMC1222-1 AND -2 VARIANTS)

Step 8 Apply CO span gas, CO span gas concentration should be in 25ppm to 100ppm CO

range

Step 9 After the signal reading has stabilized (approx 3 min) adjust Span potentiometer to

2.00VDC/100*Span gas concentration. i.e. if using 50 ppm CO

2.00VDC/100*50=1.00VDC

Step 10 If Signal > .7VDC verify CO Alarm LED Flashes, If Signal > 2.00VDC verify CO Alarm

LED Illuminates steady State

Step 11 Remove Gas, Calibration complete

AMC-1222 CO/NO

2

Multidrop

17

5.2.3 SPAN ADJUSTMENT FOR (CO) 75 PPM (AMC-1222-3)

Step 8 Apply CO span gas, CO span gas concentration should be in 25ppm to 75ppm CO

range

Step 9 After the signal reading has stabilized (approx 3 min) adjust Span potentiometer to

2.00VDC/75*Span gas concentration. i.e. if using 25 ppm CO

2.00VDC/75*25=0.6667VDC

Step 10 If Signal > .7VDC verify CO Alarm LED Flashes, If Signal > 2.00VDC verify CO Alarm

LED Illuminates steady State

Step 11 Remove Gas, Calibration complete

Figure 5-1 Calibration Procedure for 1222 CO

AMC-1222 CO/NO

2

Multidrop

18

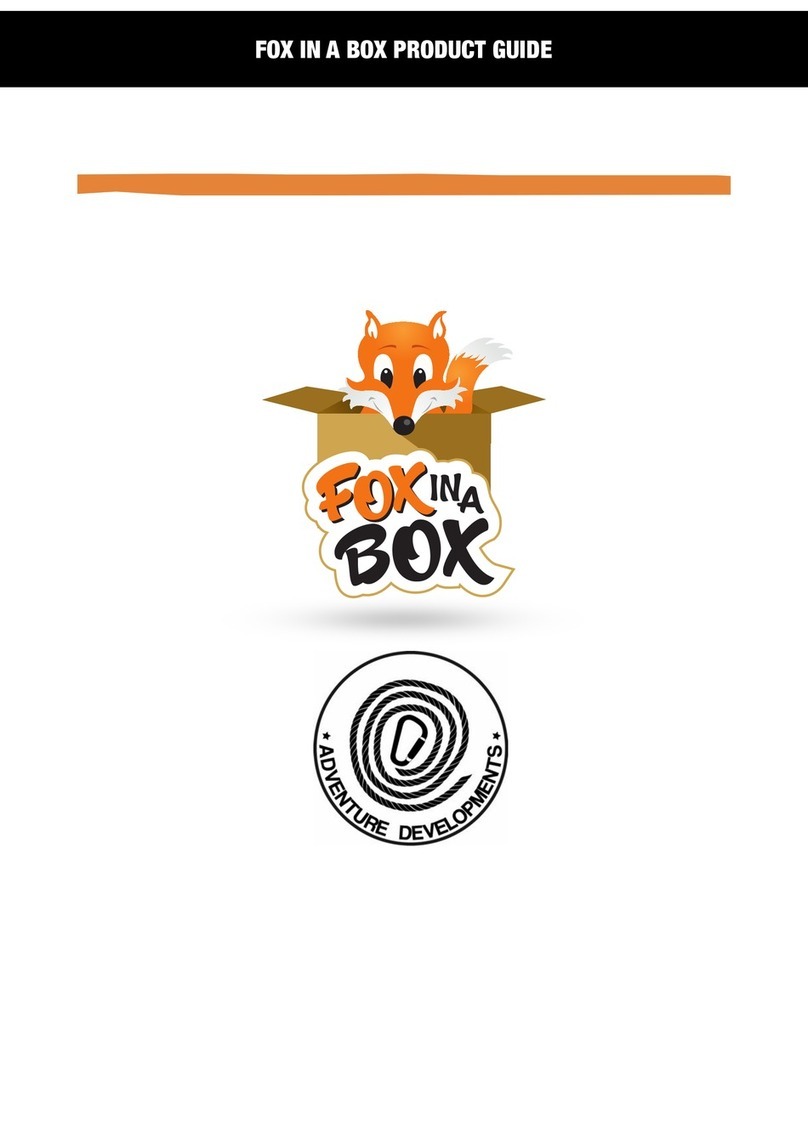

5.2.4 ZERO ADJUSTMENT (NO

2

)

Step 1 Remove cover

Step 2 Power unit from 12-24VDC Supply, Ensure green power LED illuminates. If power LED

is flashing ensure EOL (end of line) Switch(es) are set correctly.

Step 3 Set multimeter to DC voltage range suitable for reading 2.00VDC

Step 4 Connect Multimeter to COM(-) and TP1 as shown in

Figure 5-2

Step 5 Apply Zero gas @ 1L/min

Step 6 After signal reading has stabilized (approx 1 min) adjust Zero Potentiometer to

0.00VDC

Step 7 Remove calibration gas

5.2.5 SPAN ADJUSTMENT (NO

2

)

There are two possible calibration modes; A and B. They are selectable using NO2 span

calibration jumper, JP2, see section 3.1.1 item 12. Mode A is normal mode. Mode B allows the

AMC 1222 to measure only half of the calibration gas. This is useful as 2.5 or 3ppm calibration

gas is not common to purchase but 5 or 6ppm is.

Step 8 Using Teflon hose apply NO2 span gas, NO2 Span gas concentration should be in 1ppm

to 3ppm NO2 range

Step 9 After the signal reading has stabilized (approx 3 min) adjust Span potentiometer to

2.00VDC/3*Span gas concentration. i.e. if using 1.5 ppm NO2

2.00VDC/3*1.5=1.00VDC

Note: If mode B calibration is use, divide span gas concentration by 2 before using the

above calculation. i.e. if using 5ppm NO2

2.00VDC/3*5/2=1.67VDC

Step 10 If Signal > .66VDC verify NO2 Alarm LED Flashes, If Signal > 2.00VDC verify NO2

Alarm LED Illuminates steady State

Step 11 Remove Gas and unit must be in mode A for normal operation, Calibration complete

AMC-1222 CO/NO

2

Multidrop

19

Figure 5-2 Calibration Procedure for 1222 NO2

Table of contents