5

General Precautions

The rest of this manual includes step-by-step instructions for setting up the

TempHionTM, calibrating it, and using it in the field. When reading and following the

instructions in these sections, keep these very important considerations in mind:

•Do not handle the surfaces of the sensing electrodes. Oils from fingers can

“blind” the reactive surface. Rough handling can scratch the reactive surface.

•Avoid long-term exposure of silver-based sensing electrodes to bright sunlight.

•Use calibration standards that are accurately prepared. Discard standards after

use. Do not return the used standards to the bottles of “fresh” solution.

•When TempHion’s reference electrode contains filling solution, TempHion must

be stored in water to prevent evaporation of the filling solution.

•For any step-change in temperature (e.g., where calibration standards are at a

different temperature than water to be tested) allow the instrument to come to

complete thermal equilibrium before making measurements. Up to 20 minutes

may be required.

Installation and Operation

Instrument Setup

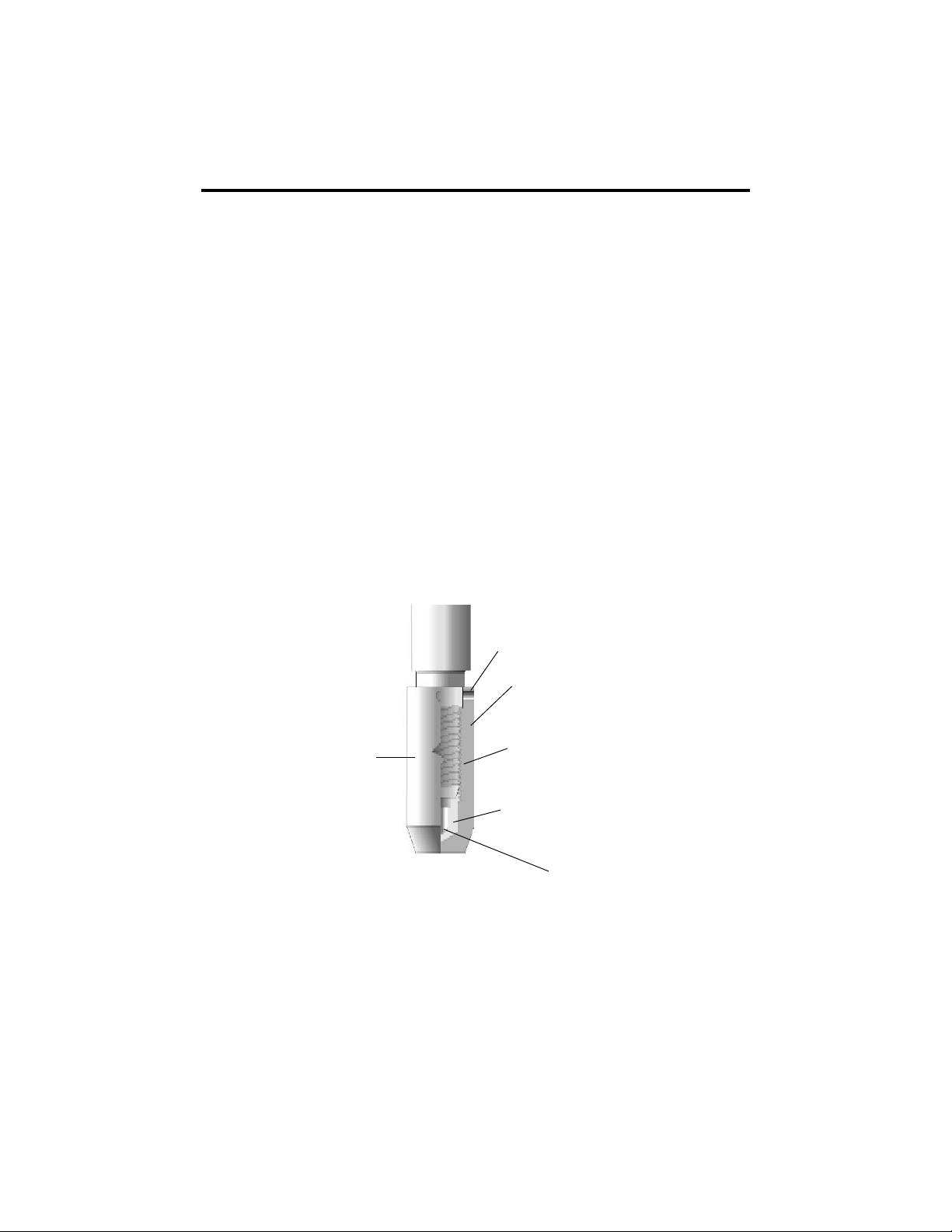

The TempHion is shipped fully assembled, but without filling solution in the reference

electrode. A bottle of filling solution and a plastic syringe are supplied with the instru-

ment. TempHion is shipped with the reference electrode chemically clean and dry, and

the instructions shown below are appropriate for this condition. If you are changing or

replenishing filling solution, or if for any other reason the reference electrode is not

completely clean and dry, please contact INW for proper preparation.

The following steps are needed to put the instrument in service:

1. Remove the white reference electrode outer housing.

CAUTION: Do not grasp the sensing electrodes.

2. Fill the white reference electrode outer housing with reference electrode filling

solution about half full.

3. With a clean tissue, wipe off any droplets of filling solution from the threads of

the bottle and bottle cap and the top and inside of the neck. Replace the red seal

and cap.

4. Holding the TempHion vertical, with the reference electrode pointing down,

reattach the outer housing. Excess solution will be forced out the top of the

outer housing. Tighten firmly. Do this over a sink, bucket, or other waste

container.

CAUTION: Filling solutions are not considered hazardous, but they can be

irritating to the skin, so rubber gloves are advised. Rinse hands or gloves with

fresh water.