3

North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim

armstronginternational.com

Make sure that the Rada MX1 is installed by a competent installer.

The product commissioning, clock (date/time) and tap set up can only be done in

conjunction with the “RADA AP1” available from the Apple App store. Time and

date setting is critical to ensure data reporting is correct.

The use of the word ‘failsafe’ to describe the function of any thermostatic mixing

valve is both incorrect and misleading. In keeping with every other mechanism it

cannot be considered as being functionally infallible.

Malfunction of thermostatic mixing valves can be detected by the use of proper

temperature checking and maintenance routines.

Certain types of system can result in the thermostatic mixing valve having

excessive ‘dead-legs’ of pipework. Such systems can disguise the onset of

thermostatic mixing valve malfunction. Ultimately, the user must exercise due

diligence to ensure that the delivery of warm water is at a stable, safe temperature

Make sure that the water delivery does not cause splashing or overflow.

Note: Clock settings are lost after a period of 24hrs without mains power.

When power is restored clock settings return to factory default (1st

February 2000) and will need to be reset via the App.

Shut off the main water and electrical supply.

Observe all local plumbing and building codes.

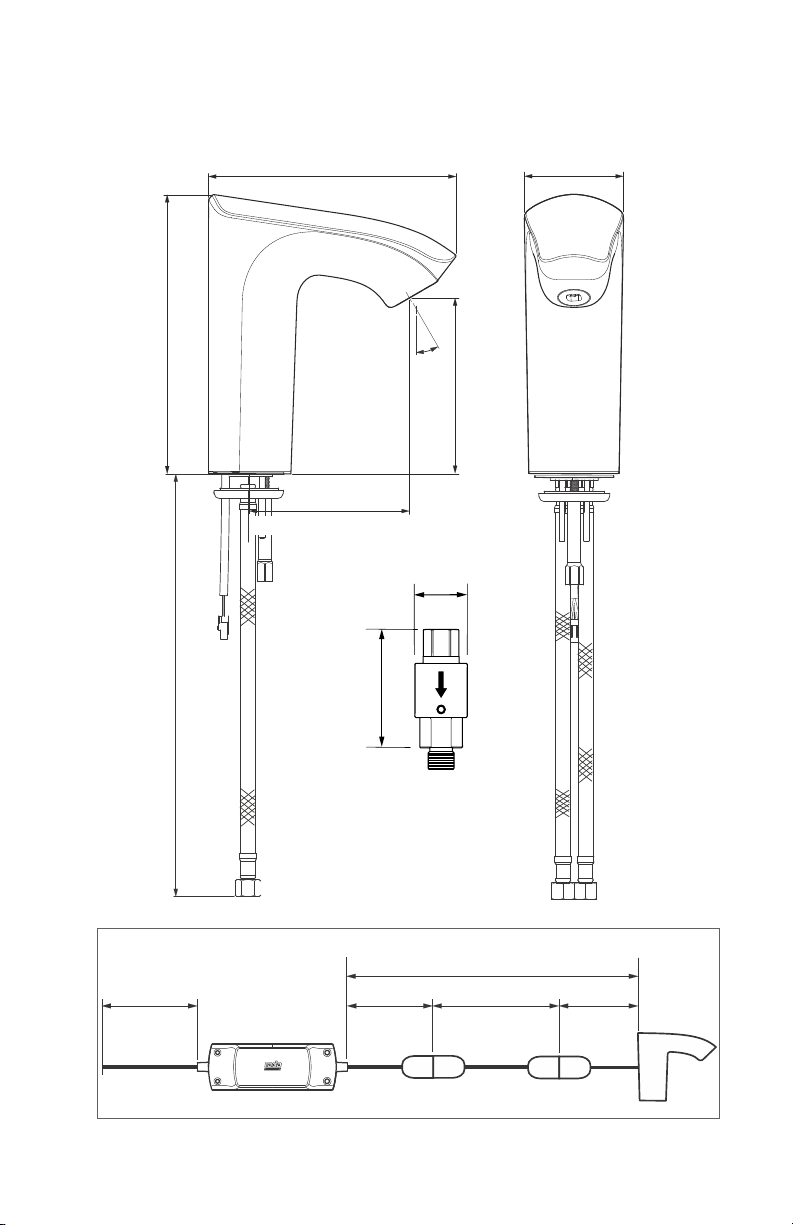

The Rada MX1 is a type 1, electronic, electrically operated, independently mounted

valve. It is intended for surface mounting and is for connection to the mains water

supply.

Isolator / Check valve / Filter housing supplied is an integral component of the tap,

failing to install will invalidate the product’s warranty.

The Rada MX1 must only be supplied from the power adaptor provided.

The power adaptor must be connected to the fixed wiring of the electrical supply

via a switched 3A fused spur.

If the power adaptor supply cord is damaged the power adapter must be replaced

by a competent person.

Where chlorine disinfection is practiced, DO NOT exceed a chlorine concentration

of 50 mg/l (ppm) in water, per one hour dwell time. Such procedures must

be conducted strictly in accordance with the information supplied with the

disinfectant and with all relevant Guidelines/Approved Codes of Practice.

Important Safety Information

General