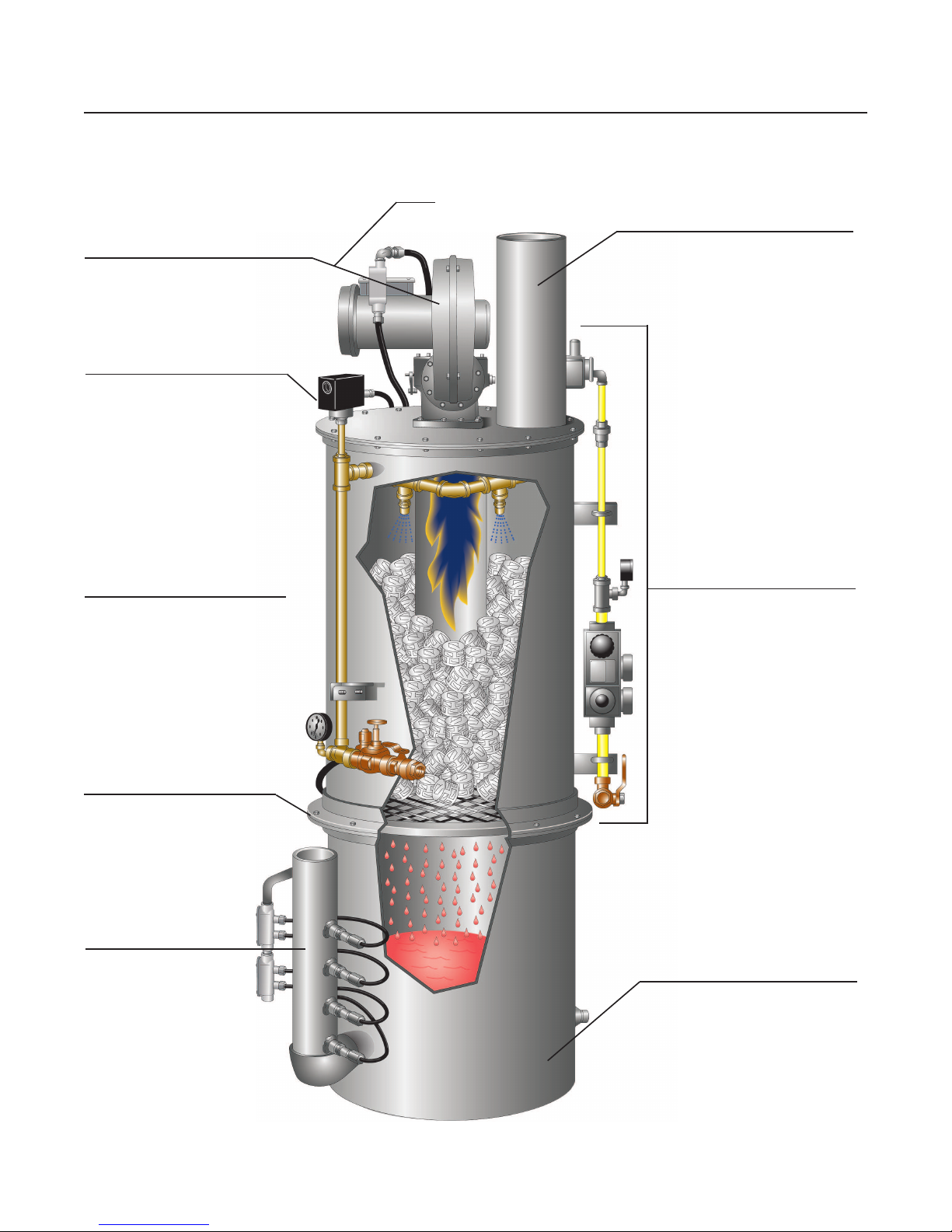

No Scale Build-Up

The Flo-Direct®CTE gas fired water heater’s unique design prevents scale build-up because there are no “hot

spots” internally or externally, and because calcium is prevented from completely falling out of suspension during

operation. As a result, if you have hard water entering the Flo-Direct®CTE gas fired water heater, you will have

the same hard water coming out.

Armstrong Flo-Direct®CTE gas fired water heaters meet CTE Standards

CTE direct contact water heaters, such as the Flo-Direct®, meet five standards not found in older, traditional-meth-

od direct contact water heater technology:

1. CTE units maintain a minimum of 99.7% efficiency in all modes of operation not just under optimal conditions.

2. CTE units have multiple thermal passes. Water and the combustion gasses (or heat from the combustion)

come in contact more than once. This ensures all of the heat or energy from combustion is transferred to

the water.

3. CTE units have a dry combustion chamber. This is vital to maintaining complete combustion at all times during

operation.

4. CTE units maintain complete combustion at all times.

5. CTE units must have a “Fail Safe” water integrity system for water quality. In any mode of failure the CTE unit

will maintain the quality of the water coming out of the heater.

Complete Combustion = Complete Water Quality.

While many traditional-method direct contact water heaters spray water directly on the flame – sometimes called

“flame quenching” – Flo-Direct®, using CTE technology, avoids this process altogether. According to the Industrial

Heating Equipment Association’s “Combustion Technology Manual*,” flame quenching promotes incomplete com-

bustion, and produces alcohols, aldehyde, formic acid, higher order acids, carbon monoxide, as well as carbon

dioxide and water vapor. Because it uses CTE technology, Flo-Direct®maintains 99.7% combustion efficiency,

while maintaining water quality at all times. In addition, Flo-Direct®has a built-in fail-safe system for heating water

that maintains water quality despite any type of failure.

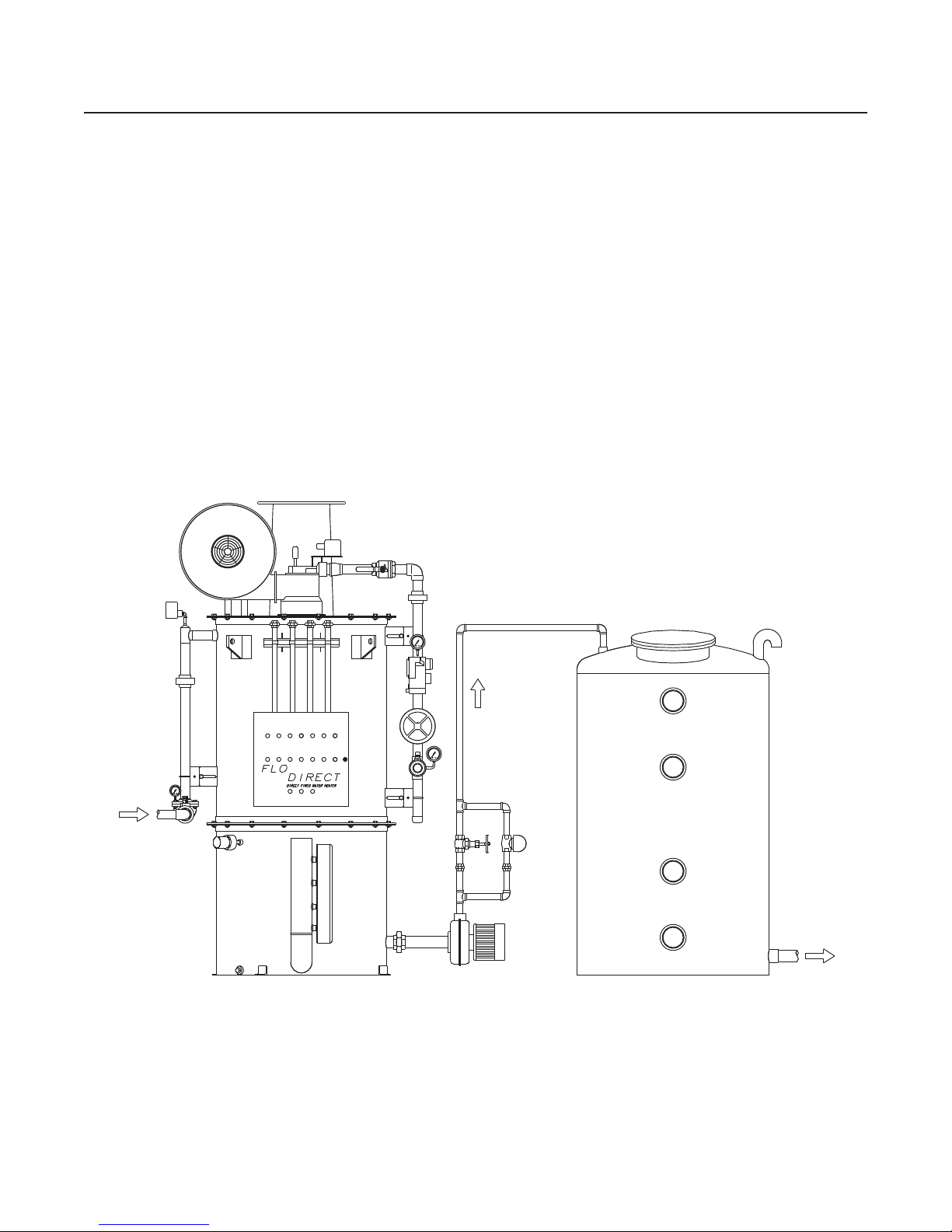

Flo-Direct®Complete Thermal Exchange Gas Fired Water Heater

It is impossible to get the full BTU value from the fuel unless you have complete combustion.

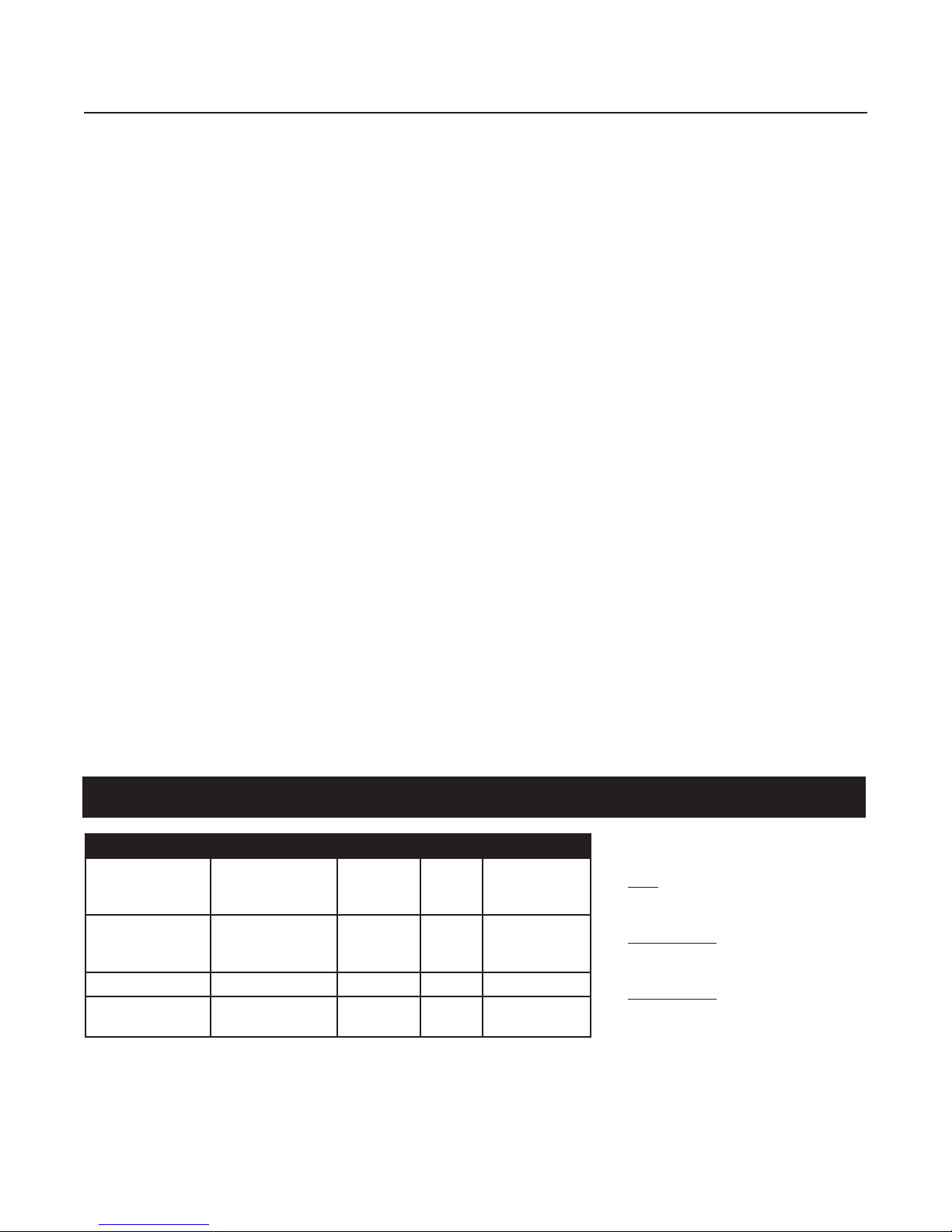

Costs for Heating 10,000 Gallons of Water

Type of Heater Typical Sizes

Btu/hour Available

Total

System

Efficiency †

Max.

gpm*

Cost to Heat

10,000

Gallons**

Commercial water

heater (atmospheric

burner)

0.1 - 2.0 MM 70 - 85% 34 gpm $159.93 @ 75%

Steam Boiler 1.0 - 50.0 MM 55 - 75% 833 gpm $184.54 @ 65%

Flo-Direct®

1.0 - 25.0 MM 99.7% 416 gpm $120.31 @

99.7%

Sizing Formulas

gpm x ∆T = AFD Model

2

(AFD model) x 2 = gpm

∆T

(AFD model) x 2 = ∆T

Formula Key

gpm = Gallons per minute

∆T = Temperature rise (°F)

AFD = Armstrong Flo-Direct®

Note: Use the Flo-Direct®sizing tool at www.armstronginternational.com/flo-direct

*Maximum gallons per minute with a 120°F rise using largest heater.

**Direct fuel costs are calculated using $12.00 per MMBtu and a 120°F rise.

†System defined from natual gas in to hot water out.