Armstrong International

221 Armstrong Blvd, Three Rivers, MI 49093 - U.S.A.

Tel: (269) 279-3602 Fax: (269) 279-3130

Designs, materials, weights, and performance ratings are

approximate and are subject to change without notice.

Visit armstronginternational.com for the most updated information.

Page 2 of 32

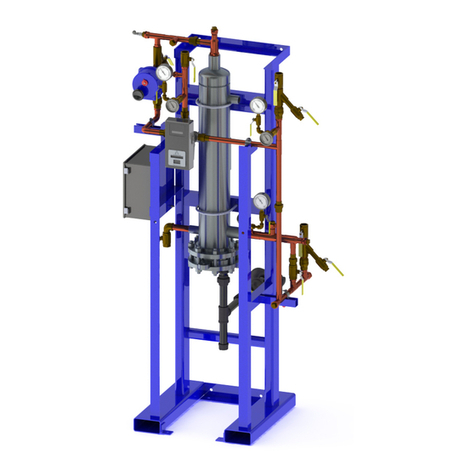

General Description

ReadiTemp®is an instantaneous water heater that heats on demand and store very little hot water. ReadiTemp®transfers heat

from steam to cold water and then precisely blends hot water, cold water, and recirculation return water (if supplied) to deliver

water at a programmable setpoint temperature.

ReadiTemp®water heaters feature an Emech®Digital Control Valve (Models E20W, E25W, E40W, E50WR, or E80WR) that

utilizes ceramic shear action disc technology to provide high-pressure differential capability and long life integrity. ReadiTemp®is

supplied pre-piped and pressure-tested.

Fitted with the electronic actuator and integrated temperature sensor, the Emech®system delivers high performance, stand-

alone, closed-loop temperature control. Even when sudden changes occur in inlet temperature and pressure to the valve,

the actuator works to aggressively minimize outlet temperature variations, making the system ideal for use in process

applications. The Emech®valve’s ability to precisely control water temperature eliminates the requirement for the following

separate components that are typically associated with steam-to-water heat exchangers:

• PID temperature controllers

• High temperature limit thermostats

• High temperature limit controllers

• Cold water injection valves

• Internal circulating pumps

• Compressed air requirements

All ReadiTemp®water heaters may be connected via 4-20mA signals for input and output temperature control and position

signals for interfacing with a building automation system (BAS).

ReadiTemp®is engineered to precision and crafted with pride to deliver years of superior performance and customer satisfaction

provided the following criteria are met:

1. Installation, commissioning, operation, and maintenance are in accordance with the recommendations provided in

this product installation and operation manual (IOM), in addition to generally-accepted plumbing, pipe-fitting, and

maintenance guidelines.

2. Periodic attention is given as necessary to maintaining the product, the accessory fittings and components, and the

overall plumbing/distribution system in sound functional order.

Standard components for a ReadiTemp®system include (see the Typical Layout Diagram):

• Emech®E20W, E25W, E40W, E50WR, or E80WR Digital Control Valve

• Heat exchanger

• Thermometers and pressure gauges

• Check valves

• Isolation valves

An application-related, low surface-temperature option is available that requires a secondary steam control valve for instances

where high mineral content in the supply water can cause excessive scaling in the heat exchanger.

Because the ReadiTemp®can be manufactured in customized configurations, there may be optional components that are not

addressed in this IOM. Armstrong reserves the right to make design or specification changes without notification.