Page 4 of 11 12/2021 REV.19

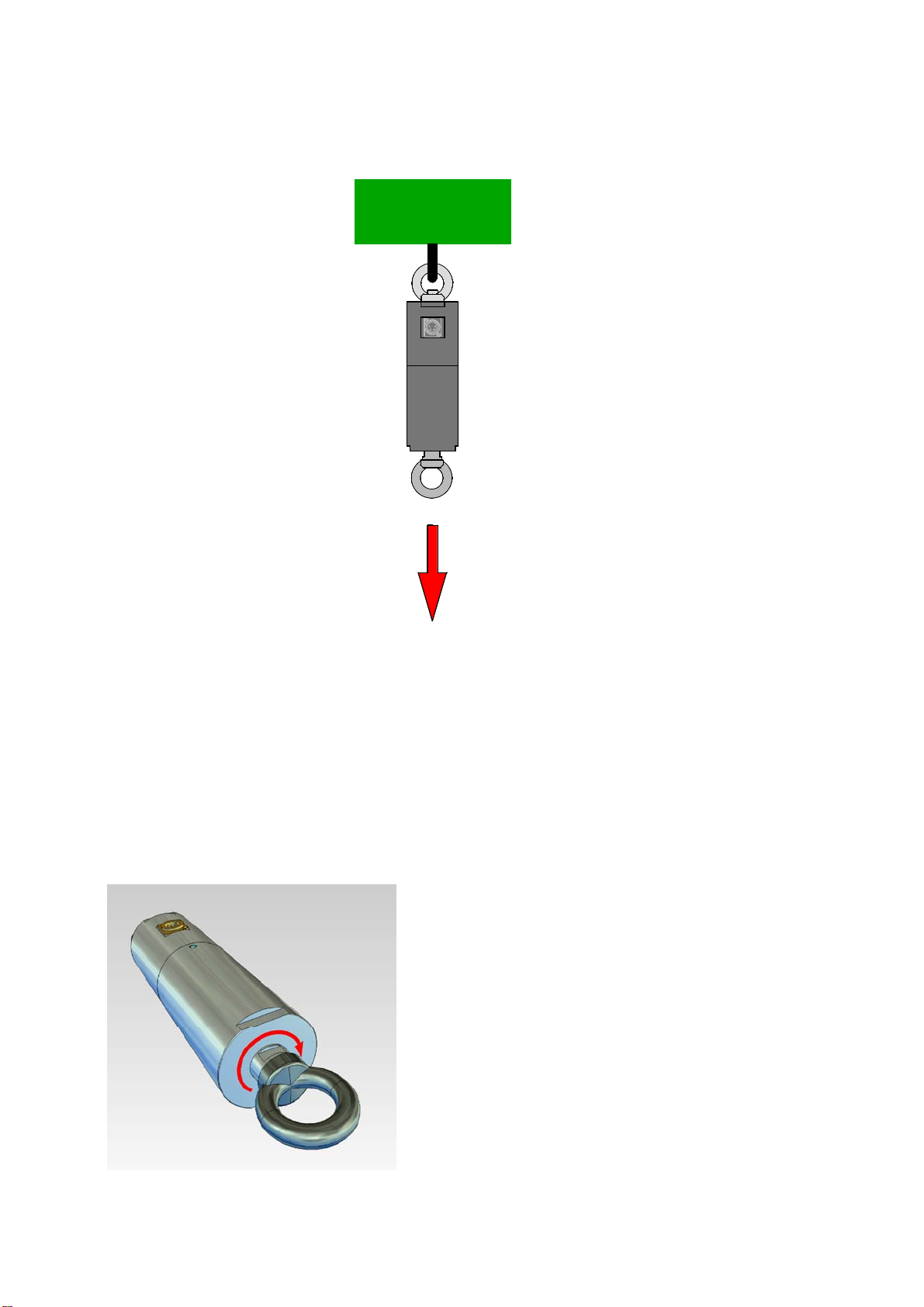

Possible existing additional safety fastenings of the mirror ball or other objects can be

connected with the lower eyebolt. In order to limit the dynamic load of the drive and

the attachment point at the mirror ball, the drop height must be restricted by a

corresponding calculation of the safety wire to less than 20 cm. The use of a safety

wire with a fall brake of the type “Major Saveking” is recommended.

The universal drive UA 500 is a product designed for the application on stages, which

is designed corresponding to the state-of-the-art in a way that risks can be largely

excluded. Nevertheless, drives and drive controls, which do not explicitly fulfill safety

functions, are, according to the general technical view, not permitted for applications

which may endanger persons due to the drive function. Unexpected or non-braked

movements can never be completely excluded without additional safety devices.

Therefore, persons must never stay in the danger zone of the drives, unless

additional adequate protective equipment excludes any danger to persons. This

applies both for the regular operation of the machine as for all maintenance and

commissioning works. In order to avoid personal injuries and damages to property,

adequate precautions shall be taken, if necessary.

The turning range of the driven element must not be entered by persons and / or

must be outside the hand area.

The commissioning, operation and maintenance may only be performed by trained

event technicians. These specialists must know and be familiar with the content of all

technical documentations of this product. Due to their technical training, knowledges

and experiences, these specialists must be able to recognize and avoid dangers.

The specialists must know the common standards, provisions and accident

prevention regulations, which must be complied with during installation, operation

and maintenance of the product. Damaged drives may neither be installed nor

commissioned in order to prevent personal injuries and damages to property.

Changes and modifications of the drives are not permitted and will result in the

voiding of all warranties and liabilities. Please observe that the drive may only be

operated in dry rooms (IP 40).