SAFEFTY INSTRUCTIONS

Readtheoperatinginstructionsinfullbeforestarting

upandfollowthesafetyinstructions.

•Keeptheoperatinginstructionsinaplacewhereitcanbe

accessedbyeveryone.

•Ensurethatonlytrainedstaffworkwiththeinstrument.

•Followthesafetyinstructions,guidelines,occupational

healthandsafetyandaccidentpreventionregulations.

•Becausetheoptionsforcombiningproducts,tools,stirring

vessel,experimentandmediumarenearlyendless,

usersafetycannotbeensuredsimplywithdesignrequirements

onthepartoftheproduct.Forthisreason,itmay

becomenecessaryforuserstotakeotherprecautionary

safetymeasures.Forexample,glassapparatusorother

stirringvesselsthataresensitivetomechanicalstresscan

bedamagedorshatteredbyanimbalance,increasingthe

speedtooquicklyortoolittledistancebetweenthestirring

elementandthestirringvessel.Userscansufferserious

injuryfromglassbreakageorfromthefreelyrotating

stirringelement.

•Uncontrolledreactionscanbetriggeredbymixingthe

heatedmaterialinsufficientlyorbytheenergygenerated

byselectingaspeedthatistoohigh.Incaseofthese

andotherincreasedoperationalhazards,usersmusttake

additionalappropriatesafetyprecautions(e.g.shatter

protection).Inanycase,whenusingcriticalorhazardous

materialsinyourprocesses,Arrow

recommendsusing

additionalappropriatemeasurestoensuresafetyinthe

experiment.Forexample,userscanimplementmeasures

thatinhibitfireorexplosionsorcomprehensivemonitoring

equipment.Furthermore,usersmustmakesurethat

theOFFswitchoftheArrow

productcanbeaccessed

immediately,directlyandwithoutriskatanytime,and

aboveall,incaseoffault.

Ifmainpowerswitchcannotbeaccessedatall

times,anadditionalEMERGENCYSTOP,switchthatcanbeeasily

accessed,mustbeinstalledintheworkarea.

•Onlyprocessmediathatwillnotreactdangerouslytothe

extraenergyproducedthroughprocessing.Thisalsoapplies

toanyextraenergyproducedinotherways(e.g.

throughlightirradiation).

•Donotoperatetheinstrumentinexplosiveatmospheres,

withhazardoussubstancesorunderwater.

•Theinstrumentisnotsuitableformanualoperation.

•Thehightorquedevelopedbythe2000RVdigitalrequires

particularcareinthechoiceofstand,crosssleeve

andanti‐rotationelementfortheagitatingvessel.

•Setupthestandinaspaciousareaonaneven,stable,

clean,non‐slip,dryandfireproofsurface.

•Youmustensurethatthestirringelementissecurely

clampedinthecouplingorchuck.

Whenusingachuck,makesuretoremovethe

chuckkeyfromthechuckbeforeturningonthedevice.

•Usestirringshaftprotectiveequipment!

•Theagitatedvesselsusedforstirringhavetobesecured.

Consideronagoodstabilityoftheentirestructure.

•Protecttheinstrumentandaccessoriesfrombumping

andimpacting.

•Checktheinstrumentandaccessoriesbeforehandfor

damageeachtimeyouusethem.Donotusedamaged

components.

•AlwaysswitchthemainsswitchintheOFFpositionor

disconnectthepowerbeforechangingstirringelement

andfittingallowedaccessories.

•Theinstrumentcanonlybedisconnectedfromtheelectrical

outletsupplybypullingontheplug.Donotpullonthecordto

disconnectpower.

•Thesocketfortheelectriccordmustbeeasilyaccessible.

•Theelectricaloutletmustbegrounded(protectiveground

contact).

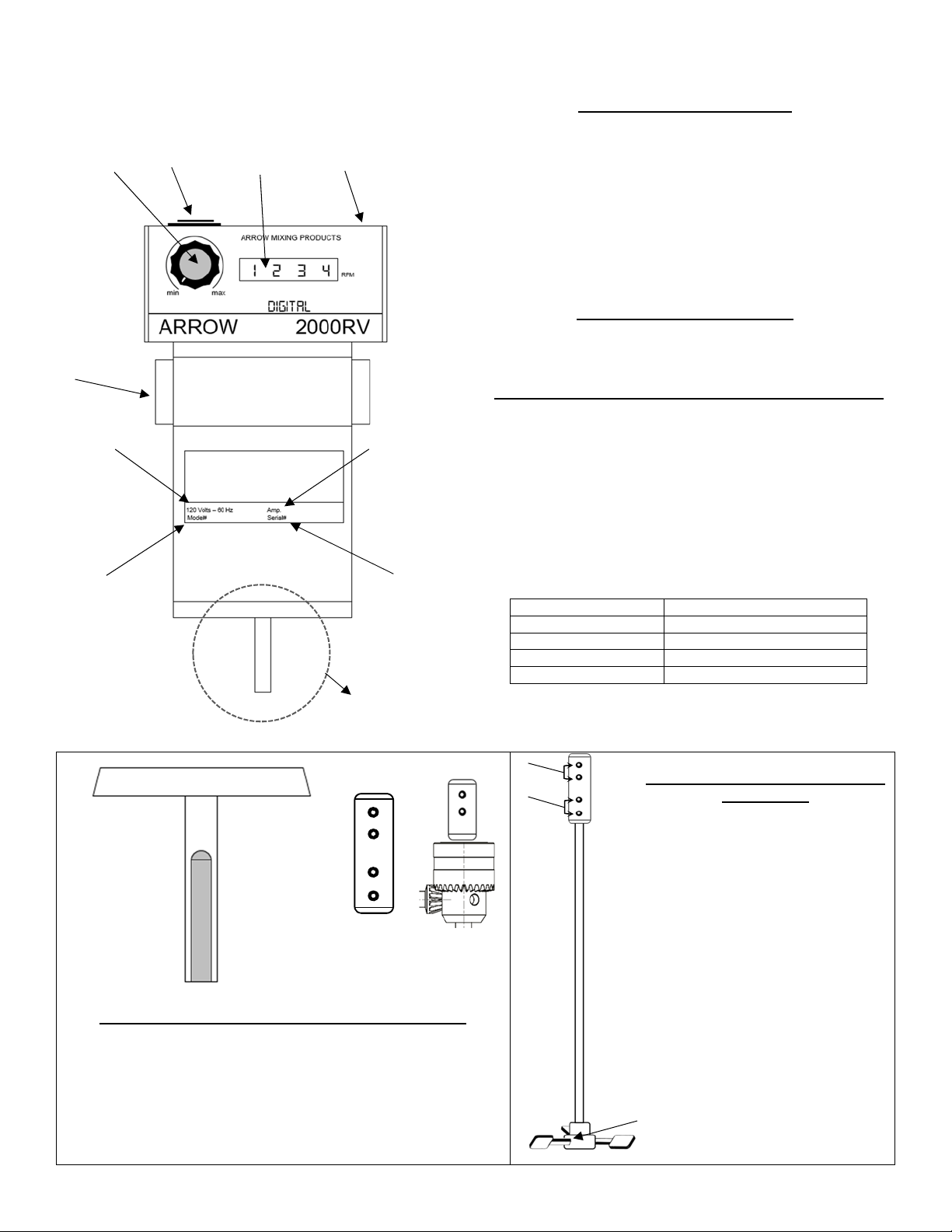

•Thevoltagestatedonthelabel(seeFig.1‐E)mustcorrespond

totheelectricaloutlet’svoltage.

•Pleaseobservethepermittedspeedforthestirringelement.

Neversetathigherspeed.

•Makecertainthattheunitissetatthelowestspeedbefore

turningthepowerswitchon;otherwise,theunitwill

immediatelybeginrunning.Graduallyincreasetorequired

speed.

•Payattentionwhensettingthespeedtoanyimbalanceof

thestirrertoolsandpossiblesprayingofthemediumto

bestirred.

Neveroperatetheinstrumentwiththestirrer

toolsrotatingfreely.Ensurethatpartsofthebody,hair,jewelry

oritemsofclothingcannotbetrappedbytherotatingparts.

Theoperationofafreerotatingshaftendis

dangerous,therefore,forsafetyreasons,onlyinsertthestirring

toolintotheupperedgeofstirringvesselwiththemotoroff.

Whenfinished,turnthemotoroffbeforeliftingthestirringtool

outofthevessel.